Innovations in bagging and closing equipment for snacks and baked goods

Upgrades include efficiency, hygienic design, smart technology and sustainability.

Packaging equipment manufacturers are upgrading bagging and closing equipment to improve operational efficiency and hygienic design, while also adding touches of smart technology and sustainability. This is good news for snack producers and bakeries as they strive to meet consumer demands for product freshness, and retailer demands for improved shelf presence.

In-demand features

Flexible packaging and standup pouches are fast-growing formats, driven by cost, convenience and aesthetics. High-value attributes for consumers, as well as retailers, include resealability for freshness, as well as vertical formats for shelf economy without compromising package appearance.

John Panaseny, CEO, Rovema North America, Norcross, GA, sees three key trends in this area:

- More transition to standup bags. As the technology for making these bags on vertical machines has improved, interest has increased. One reason is they save on floor space.

- Continued interest in hygienic design. Fewer machines use tubular steel for frames because of hollow spaces that can harbor bacteria. To address this concern, Rovema re-launched its machine portfolio with the BVC Series.

- A move to smart technology. Some areas that are beginning to gain traction are live machine monitoring for predictive maintenance and the use of machine sensors to anticipate part failure.

Steven Wolfe, general manager, TNA North America, Dallas, sees increased levels of speed and automation in bagging and closing equipment. The latest advances have resulted in VFFS technology that is able to strike a balance between high packaging speeds, low waste and quality. “For example, our tna robag 5 VFFS system and tna ropac 5 case packer offer speeds of up to 300 bags per minute with less than 0.5 percent waste within a small footprint,” he says.

As for consumer demand, millennials have demonstrated a preference for single-portion snack foods over traditional sit-down meals, and the number of one-person households is rising. As a result, bag sizes have gradually decreased over the years. “In fact, 100-calorie, bite-size snack bags are now ubiquitous in grocery aisles. For many manufacturers, reducing the size of their bags is the best way to offer consumers convenience and calorie control without jeopardizing brand loyalty,” Wolfe adds.

Jimmy Belval, product team leader, AMF Bakery Systems, Richmond, VA, sees growth in the artisan breads segment, which affects bag characteristics. “We have some customers seeking packaging solutions with paper bags to create an in-house, craft baking appearance. Also, we have adapted our Mark75 Bagger to enable customers to bag modified-atmosphere packaging wrapped products in conventional poly bags. We are helping other customers by converting the bag wicket system to accommodate both poly and paper bags.”

Ongoing advancements

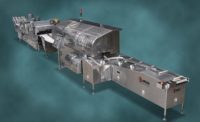

Rovema North America has unveiled the BVC 145 Twin bagger, which can produce up to 500 bags per minute. It features auto web tracking and independent cross seal drives. This allows greater control of the film and a high degree of seal integrity, which results in longer shelf life, according to Panaseny.

Lawrence/Hartmann Equipment, El Monte, CA, offers an array of automatic bagging and sealing machinery that can be provided with multiple closing options to operate within the unit, with goods discharged ready for boxing or trays. “Heat sealing with multiple seal closure or 12-mm band seal are most popular for flatbreads, offering the best way to close premade bags, which incorporate a zip lock or other resealing feature,” says Glenn Shelton, product manager.

All Packaging Machinery Corp., Ronkonkoma, NY, manufactures bag sealers for customers based on their specific application requirements. Its line is modified for bag types and requests for packages-per-minute requirements. “Airtight seals help keep products fresh longer; however, the choice of the bag made by the customer is important, as well,” says Lynn Miranda, sales and marketing manager.

All Packaging Machinery also manufactures vertical and horizontal band sealers. “Products in standup pouches, such as snack mixes and baking mixes, are most often sealed on our vertical conveyorized band sealers. Products such as tortillas or flatbreads—items that need to be laid flat on a conveyor—are often sealed on our horizontal conveyorized band sealers,” Miranda notes.

Advances are being made in the area of twist ties, clips and zippers, as well. Burford Corp., Maysville, OK, offers Twist Tyer machines for horizontal or vertical fill applications that operate within a wide speed range. “We have three models available, and each can help improve freshness and increase production speeds in small, mid-size and high-speed bakery production lines. Twist tie materials are available with both metal cores and in all-plastic versions,” says Mitch Lindsey, senior sales account manager.

Burford Corp. also offers a Tamper Evident Closure System (heat seal), which can be used by itself or with a Twist Tyer. When coupled with a Twist Tyer, it provides tamper evidence along with a method of reclosure. “Unlike traditional band sealers, the design allows for line stoppages without melting through the package,” Lindsey notes.

A reliable reseal feature is most likely to motivate shoppers to select one product over another, according to Erin Henry, global director of innovation and marketing, Zip-Pak, Carol Stream, IL. “A zipper reseal feature ensures that a package is securely closed to seal in freshness and prevent food spillage and spoilage. Zip-Pak applicators integrate with many types of packaging machines, ensuring that applications are efficient. Sealing the zipper to the package ensures that it will not become detached during downstream processes.”

Sustainability matters

A key industry trend is sustainability, as food manufacturers look for systems that will help them meet green objectives. “Our packaging equipment is designed to use minimal air and power consumption, and comes with standby options to turn off power to non-essential functions when not in use,” Wolfe says.

Kwik Lok, Yakima, WA, has embarked on a Fresh Start initiative that includes new products and process improvements designed to lower the carbon footprint of its products, according to Ron Cardey, vice president of sales and marketing.

Kwik Lok recently worked with Mathews Marking Systems to develop an eco-friendly 912 Fiber Laser coding system. “The system eliminates waste while combining reliability, efficiency and virtually no consumable costs,” Cardey says. The company also plans to launch a sustainable bag closure lock later this year. “It will feature a blend of biopolymers and polyethylene called ‘NuPlastiQ’ to create the same quality product with 50 percent less fossil fuels needed in the manufacturing process.”

Ultrasonic sealing is also making inroads in snack and bakery production. The baked goods segment needs innovations for self-closing and resealable packaging, because current versions do not work well in areas where there is a lot of fine powder (e.g., flour from baking), according to Sean Riley, senior director, media and industry communications, PMMI, Reston, VA.

Ultrasonic sealing is one technology that thrives in this area. “Rather than glues or solvents, vibrations at the interface of the plastic parts being joined cause the plastic material to soften and flow in a fraction of a second. When the material is pressed together and solidifies, the bond is made. Baked goods producers can use ultrasonic technology, because it seals right through the product for an airtight seal,” Riley explains.

Ultrasonic sealing is now an established alternative to heat sealing—providing tight seals, high output and the ability to monitor seal quality, according Ken Hundley, sales engineer, Herrmann Ultrasonics, Bartlett, IL. “For packaging materials with thermoplastic layers such as capsules, pouches, cups and trays, ultrasonic sealing offers a number of technological advantages.”

The technology also can help snack producers and bakeries in their quest to decrease waste, material usage and package size. “Ultrasonic sealing can contribute to this initiative, because the process can create high-quality and repeatable hermetic seals even if product contamination is present in the seal area,” Hundley notes.

Manufacturers still face challenges when designing bagging and closing equipment for snack and bakery plants. One of the biggest is temperature control. “Creating a zipper that can handle the transition from a warm environment to a frozen environment requires expertise in material application for both the zipper and film to which it is attached,” says Henry.

Creating a space-conscious solution is another challenge, adds Cardy, who notes that bakeries have become increasingly complex, while the space available has not grown along with equipment needs. “As we develop solutions to help our customers, we are aware that they must fit within the current line structure and take up the least amount of space possible.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!