Home » sanitation

Articles Tagged with ''sanitation''

MADISAN 75 sanitizer kills human coronavirus

Ideal for food processing and foodservice facilities

May 13, 2020

Advances in bakery pans help streamline production

Pan release agents aim for better environmental health, while washers target versatility

March 13, 2020

Improving food safety and sanitation through facility layout and design

Streamlining sanitation needs from the start will improve food safety and cleaning efficiency

February 18, 2020

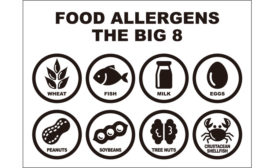

Allergen control and training for snack and bakery production

Companies rise to the challenge of allergen control

January 20, 2020

Hygiene, flexibility among top priorities for belt, conveyor customers

Customers want easy-to-use belts and conveyors that also maximize energy efficiency and durability.

January 15, 2020

Companies employ pest prevention to keep snack and bakery facilities safe and sanitary

Pest-prevention strategies depend on the types of products produced, facility type, and other factors

December 11, 2019

Improving food safety through sanitation, managing carcinogens and implementing new technologies

Sanitation, carcinogens and new technology bring food safety into focus

December 10, 2019

Machine essentials for lubricants in snack and bakery production

Proper storage, use, employee training and documentation helps ensure safe use of machine lubricants

November 19, 2019

Snack and bakery customers seeking new slicers and cutters look for innovation

Shapes, sizes, sanitation, automation are among the top-ranked criteria for today’s slicing and cutting equipment.

November 15, 2019

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing