Home » sanitation

Articles Tagged with ''sanitation''

Alfa Laval Fluid Handling Application & Innovation Centre opens in Denmark

The center will reinforce the company's technology leadership within hygienic fluid handling and put Alfa Laval squarely at the forefront of customer engagement, product innovation and optimization of customers' processes.

October 8, 2020

Snack and bakery companies uphold infrastructure maintenance

Ongoing maintenance is important for both new and legacy facilities.

September 24, 2020

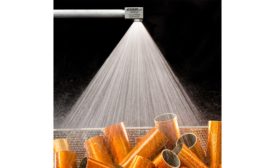

Washing systems help automate sanitation for bakery pans and more

Snack and bakery customers have options to streamline procedures for washing pans, buckets, and more.

August 21, 2020

Updated bakery mixers for improved safety and automation

Manufacturers of dough mixing equipment add improvements related to safety, preserving product quality, and automation.

August 18, 2020

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing