Fryer customers focus on flexibility, adaptability, energy efficiency

Other priorities include frying more than one product concurrently, handling both older and newer snack and bakery formulations.

The Bottom Line:

- Flexibility in frying

- Energy efficiency is king

- Uptick in plant-based foods inquiries

Snack food and wholesale bakery companies in the market for new fryer equipment traditionally have focused on which machines keep down the cost of producing their SKUs, the oil turnover time, and the quality of the filtration systems that keep the oil clean.

More recently, such fryer customers also have been increasingly focused on priorities like the flexibility to fry more than one product at a time, the ability to seamlessly handle both old-school products like tortilla chips as well as newer snack and bakery formulations, the capacity to produce more on an hourly basis, and more energy-efficient solutions.

“It becomes more challenging to ensure that [fryers] can be designed to suit two different products that would have different heat requirements and cook times,” says Neil Anderson, vice president of business development, PPM Technologies, Newberg, OR. “They would have to have the flexibility to adjust from maybe a 2½ minute cook time to a 3½ minute cook time.”

Anderson adds that his company has seen an uptick in inquiries coming from traditional product sectors like tortilla chips, other tortilla-based products, and bread-based products, but that fryer manufacturers need to also serve manufacturers of rising categories, as well. “One of the newer industries [in that regard] is plant-based foods,” he says.

Customers of tna Processing Solutions, Coppell, TX, have several priorities, according to Daniel Luna, processing solution specialist, TNA North America. “The tendency is toward higher hourly capacities, more energy-efficient solutions, and easy to set up and maintain systems that offer flexibility in different product applications—different cut styles, coating, different textures, reduced oil content for low calorie-per-bag products, etc.,” he says.

“The need to reduce the CO2 footprint of the food industry becomes an ever-more important aspect, whereby large industrial fryers cannot simply be electrically heated due to high energy requirements to heat product and evaporate water, simply because of physics; smaller snack fryers can, and we offer these solutions so that customers can run on green electricity,” Luna adds. “Regulations as set out in the Paris Treaty as well as even more ambitious goals set by multinational companies themselves, require tna to develop solutions that are helping to achieve those goals to move from fossil-based energy to renewable energy sources.”

Company

PPM Technologies

Featured Product

Snack Frying System, Linear Frying System

In recent months, PPM Technologies has added a gas-fired model to its line of rotary fryers designed for extruded and pellet snacks that ideally cook for between 40 and 60 seconds, Anderson says. The Snack Frying System comes in three sizes based on the capacity of the oil volume each one contains, designated as the SFS35, SFS80, and SFS140.

“Instead of being linear, it’s more like a Ferris wheel, inside a chamber, which pushes the product down under the oil at 3 o’clock and as the wheel rotates, then exits at 8 o’clock. The speed of the wheel determines to cook times as it’s being conveyed through the oil,” he says.

The traditional model of this Snack Frying System was powered by electricity that heated the oil, but the gas-fired model, which comes with an immersion tube that dispenses the heat into the oil chamber, will save costs in the United States, where gas in cheaper than electricity—and that’s the market it’s aimed at, Anderson says.

“In Latin America, it’s the opposite,” he says. “They don’t have any natural gas down there. There’s a cost-benefit and sustainability [factor], since the gas-fired design will last much longer than the electrical elements. … The footprint, which is the same as when it was electric, is also a main benefit—it’s a much smaller footprint than the linear footprint.”

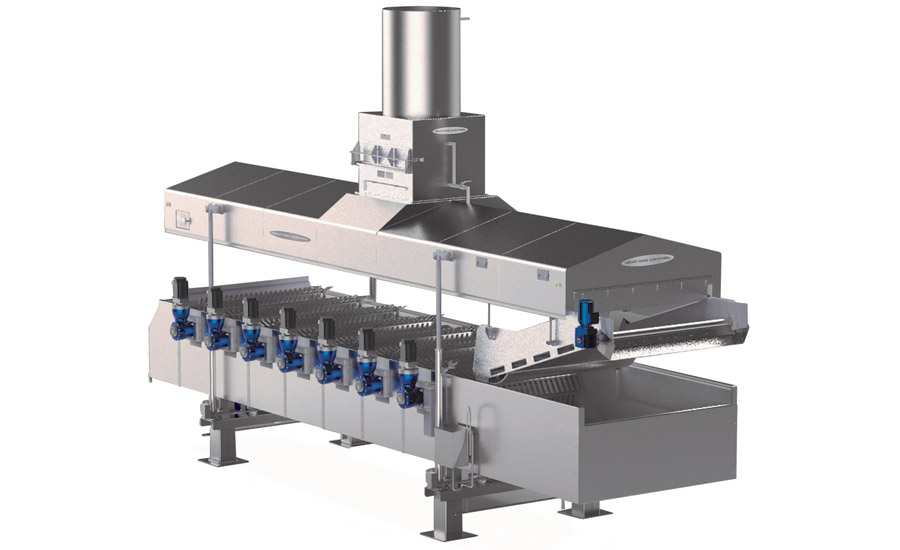

PPM Technologies also offers a range of products known as the Linear Frying System that are also gas-fired and designed around an immersion tube. They can be sized based on the volume and type of snack food or bakery item, Anderson says.

“They can have a variety of different belt options to suit the different products to be conveyed, not only for snack foods but for finished goods such as spring rolls, breaded or battered poultry products, and protein products,” he says. “They come with a selection of filtration systems to suit the types of products that are being fried.”

Company

Heat and Control Inc.

Featured Product

Dynamic Action Fryer, Universal Product Cooker, OilSaver Filtration System

Heat and Control Inc., Hayward, CA, offers various options for snack food and bakery manufacturers to meet the ongoing trends such as a wider array of product desires, increased sustainability, and improved operator safety, says Don Giles, processing systems.

The Dynamic Action Fryer can produce a spectrum of snack products such as potato chips, plantain chips, multi-grain chips, extruded snacks, pellet snacks, and corn curls, Giles says. The “compact, flexible, and versatile fryer … does the job of multiple fryers because operators can easily adjust the elevation, speed, and motion of its product control paddles to produce different frying conditions,” he says. “The DAF automatically maintains both optimal oil temperature and safe external heating and adjusts quickly to changes in product load.”

The Universal Product Cooker, which uses independent fryer modules integrated into one continuous system, can be used for traditional and kettle-style potato chips, plantain and multi-grain chips, and pellet and extruded snacks, Giles says.

“This versatile fryer system allows operators to adjust dwell time, temperature, and oil flow in each module to customize recipes and to create almost unlimited styles of chips with specific texture, moisture, and color qualities,” he says. The fryer “costs less to operate than separate batch or continuous fryers producing the same capacity. … The easy-to-use PLC control stores multiple recipes so operators can change products in minutes, and the cooking oil is continuously filtered in each frying module for superior product quality.”

Aimed toward products like coated protein products, peanuts, and tree nuts, and donuts, the OilSaver Filtration System from Heat and Control preserves frying oil quality by removing solids like coating and crumbs to extend the oil’s life, with continuous, high-efficiency filtration down to 10 microns, Giles says.

“It keeps frying oil in good condition on a continuous basis, maintains consistent color, reduces generation of free fatty acids, and minimizes the chance of scorching and off-flavors,” he says. OSF is a pressure-less oil filtration system which utilizes vacuum technology, making it the safest option available by eliminating the chance of spraying dangerous, hot oil from the system. During production, high-efficiency slipstream filtration takes place.”

Company

tna Processing Solutions

Featured Product

BatchPro, conti-pro

tna in is various stages of developing several initiatives to boost capacity and energy efficiency, applying flow modeling to newly designed fryers aimed at improved, more consistent product quality for the customer, with fewer sorting losses post-frying, Luna says. The company focuses primarily on the snack food and potato processing industry, with applications like potato chips, french fries, nuts and corn-based snacks, he says.

Among the newer initiatives from tna is the upgraded BatchPro fryer, used to produce batch or kettle-style chips, Luna says. “The updated features include a deeper tank but the same oil volume, lower hood placement during operation, improved sediment removal system, and updated control logic allowing for better control over finished product,” he says.

As such, BatchPro addresses customer desires for improvements in oil quality, control of the frying process and higher fuel efficiency, using filters, better controls, and a high efficiency burner, Luna adds.

tna also has upgraded its conti-pro pellet fryer, used for a variety of pellet products, to incorporate a triple-belt turnover feature, Luna says. “As pellets are offered in many shapes, with new shapes arising all the time, some shapes hold pockets of oil from the frying process,” he says. “The triple-belt turnover feature ensures the pockets of oil are removed from the pellets before exiting the fryer. Since the triple belt is under the hood, the oil drips back into the frying zone. Of course, the oil volume in the frying zone is minimizing in order to provide an adequate turnover rate, usually between two to four hours.”

Overall, tna addresses customer requests for full-line process, distribution, and seasoning solutions by building fryers for many different product applications, with technology in both batch and continuous frying systems, and under atmospheric or vacuum conditions, Luna says. “At the same time, we understand that some customers prefer to deal with unit operation specialists, where we are flexible in lining up with tna-chosen partners or customer chosen solutions,” he says.

Company

Kalsec

Featured Product

Herbalax, Duralax

Kalsec, Kalamazoo, MI, offers products with natural antioxidants like rosemary extract that can be infused into commodity oils to provide cost savings, along with similar stability as other types of oils that are either less healthy, have shorter shelf life—or have become difficult to procure in the past several months, says David Johnson, director of product management.

Typically, high oleic oil such as sunflower oil is used in frying operations because of its stability, Johnson says. But with 75% of sunflower oil originating Ukraine and Russia, the supply chain has been challenging since early 2022. “What does this mean?” he says. “You can’t get the oils and still need greater stability.”

The other options are moving to a lower shelf-life oil without the high oleic properties, which food manufacturers tend to eschew, or moving to palm oils, which prompt concerns about saturated fat content and sustainability, Johnson says, adding that his company’s Herbalax and Duralax products square that particular circle.

“You reach the stability of high oleic oils or even greater,” he says, adding that they’re useful in making fried chips, baked snacks like crackers, and extruded snacks. “When you take commodity vegetable oil and add Kalsec’s Herbalax or Duralax, you get cost-savings and reach the same stability. Now, with the supply chain issues, that’s brought [additional] customers to use them over the last four or five months.”

At the usage level that Kalsec prescribes, the natural antioxidants do not impact the sensory aspects of the oil, Johnson says, adding that he’s hearing from customers and suppliers that the sunflower oil shortage is likely to continue into next year. “And if you can get it, you’re going to be paying more than you used to,” he predicts.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!