Product handling for secondary packaging goes robotic

Flexible, automated systems reduce labor-intensive processes

Product-handling equipment—including cartoners and case erectors, packers and loaders—are more automated and more flexible than ever, offering quick changeovers between package formats. They’re able to erect, pack and seal multiple package formats, including shelf-ready packages, stackable club store trays, standard regular slotted containers, flange seal cases and more. Robotics is a big part of these systems.

Automation has increased to reduce labor-intensive processes, on robotic and traditional equipment. OEMs integrate more delta robots with traditional machinery to offer flexibility. Also, many snack and bakery producers want to merge products from several lines into a single case packer, which requires sophisticated handling systems.

Complex formats

The latest product handling equipment is able to create more complicated carton formats. “New systems are capable of running complicated carton types such as hanger tab, gable top, tray or fifth panel style cartons. In addition, shelf-ready packages are being used on both wrap-around case packers and traditional end load/top case packers,” says Eric Langen, vice president, sales and marketing, AFA Systems Ltd., Brampton, Ontario.

The market is primed for more retail-ready packaging, according to Peter Fox, senior vice president of sales, Somic America Inc., Wytheville, VA. “One area that has yet to take off in the U.S. is the two-piece tray and cover, or tray and hood. It’s just a matter of time until this becomes the preferred solution here. Once retailers start to see more of these package styles, they will demand it, as tearing apart cases utilizing perforations is rather archaic. European-style retail-ready is coming to the U.S.”

The Somic-Flexx III can pack primary packages in a flat, nested position or a standing display orientation. The machine also is designed to use single or multi-component packaging: one-piece corrugated blanks for standard wraparound shipping cases and two-piece tray and hood for retail-ready presentations. Stand-up pouches, flow packs, rigid containers and other items can be collated, grouped and packed in various formats. This ranges from open or wraparound trays, to paperboard cartons and trays with covers.

The LSP Series case packer from Delkor Systems, St. Paul, MN, can pack pouches and bags into shelf-ready packages, standard cases and stackable club store trays—all in one compact-footprint machine. “This allows producers to supply a range of packaging solutions to their retail customers without investing in additional machines. The LSP series robotic loader couples with Delkor’s case erector and case sealer. All three machines are multi-format capable,” says Rick Gessler, vice president of engineering and marketing.

Robotics advances

“Advances in the areas of collaborative operation, machine safety, simplified programming, space-saving designs, machine vision, gripper designs and sanitation allow robots to work in areas that were once dominated by manual processes,” says Dean Elkins, segment leader, material handling, Yaskawa America Inc., Motoman Robotics Division, Miamisburg, OH.

More industrial automation companies, such as Rockwell Automation, are providing motion control for robotics, according to Langen. “This benefits OEMs, as it allows us to integrate the motion control on a robot with our controller for a case packer, cartoner or palletizer. End users also benefit, as they deal with a single control platform for their machinery.”

Because of recent advances in robotic gripper and control systems, high-speed pick and place is now a viable option for automating product packaging, according to Carl Vause, CEO, Soft Robotics Inc., Bedford, MA. “One common area we see is primary packaging from a conveyor into a flow wrapping system, and then secondary packaging of product into cartons. These solutions can run at high speeds across multiple SKU lines without product damage.”

End-of-arm tooling (EOAT) for picking and handling food products and packages continues to advance, as well. “EOAT is becoming far more flexible through the introduction of articulating tools and sanitary polymer materials. These tools can be fabricated in a way that allows them to work at high speeds without damaging products,” Elkins says.

“Tooling can be tested prior to production in a food producer’s plant so corrections can be made as needed. Some EOAT can handle delicate bakery products, sometimes faster than robots can cycle,” says Branko Vukotic, president, PMI Kyoto Packaging Systems, Elk Grove Village, IL.

Ongoing innovations

BluePrint Automation, South Chesterfield, VA, has unveiled the Spider 300v, which combines spider-style-pattern building robots with six-axis case loaders. “This design increases achievable product and case rates. Another benefit is its narrow machine footprint and the ability to run both vertical and horizontal patterns simultaneously. In addition, 3D vision recognizes and corrects product orientation, greatly reducing machine jams,” says Jason Hogue, southeast regional sales manager.

A-B-C Packaging Machine Corp., Tarpon Springs, FL, has introduced the Model 600 robot packer, which has a high-payload robot, servo-powered product feed and case/tray transport, as well as multiple package transport options. “The standard design is easily scalable to add packing options, speeds or product configurations, and custom-engineered designs are available that provide simple solutions for multiple production lines,” says Bryan Sinicrope, vice president sales and marketing. In addition, the company offers the Model 700 robot palletizer, which runs cases, display trays, bags or totes with multiple SKUs.

PMI Kyoto Packaging Systems recently introduced the Tri-Seal Top-Load Cartoner, which integrates a pick-and-place delta robot to achieve more-consistent, high-quality cartons and accurate product fills—all at high speeds and with less downtime. This modular, customizable cartoner also can accommodate a second delta robot at the machine infeed to fill up to 60 cartons per minute, depending on the packaging. The robots feature lightweight carbon shafts that allow it to handle up to 120 cycles per minute. EOAT, buckets and containers can be changed to carton flow-wrapped, bagged or thermoformed packages.

Conveyor belts are another key aspect of efficient product handling. Multivac Inc., Kansas City, MO, offers a product-infeed-conveyor belt design that melds the frame of the upstream conveyor with the frame of the thermoformer, bringing the product closer to the package. “As a result, the distance traveled from pick-to-place position is reduced, enabling higher speed operation. Also, the integrated nature of robotics on the discharge end means the footprint of the automated system is more compact,” says Cem Yildirim, market development sales manager.

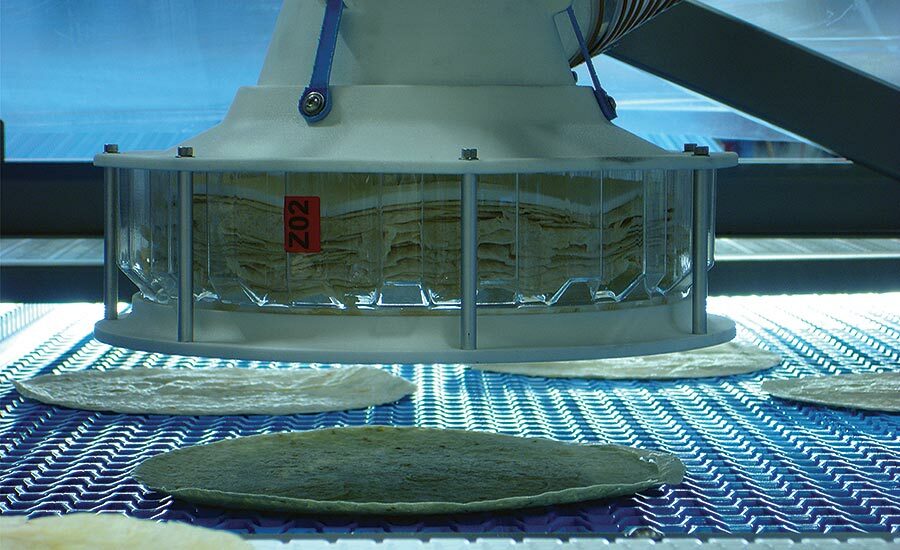

Somic America has developed a smart belt system that uses a vacuum track, which enables it to accelerate and decelerate products without physically pushing, turning or grabbing them. This reduces potential product damage or misshaping of delicate items. “The smart belt system can be configured in a wide variety of applications and is especially useful for multiple line merging scenarios prior to reaching case packers or cartoners,” Fox says.

Looking ahead, JLS Automation, York, PA, is in the process of launching JLS TRAK, a product transport system that is based on a new technology from B&R Automation. “We believe it will change the way food producers think about packaging lines in the future,” says Craig Souser, president. Applicable to variety packs and batch-of-one applications, the system will solve issues that involve bottlenecks due to rigid connections between operations, traceability of products, and balanced flow of products/packages and sorting/grading challenges, he predicts.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!