Items Tagged with 'automation'

ARTICLES

Duravant acquires Pattyn Group

Producers prioritize packaging equipment offering flexibility

Bakers and snack makers seek ovens and proofers with advanced capabilities

Where there's automation, there are belts: Ammega

Packaging innovation can cut snack and bakery labor costs

Penske implements Cimcorp's automation solution

Belt and conveyor users prioritize sanitation, automation

Technology can alleviate supply chain headaches: PMMI

Yaskawa Motoman doubles automation production space

IMAGE GALLERIES

New Processing Equipment: February 2023

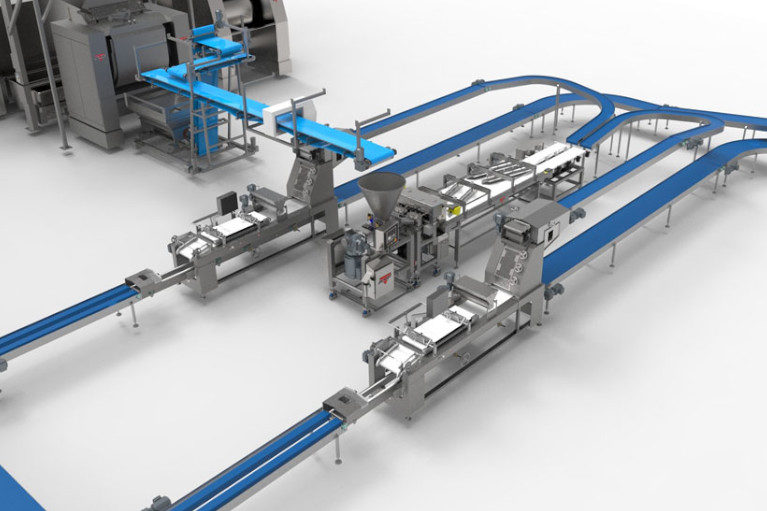

Dough handling can be a dangerous, demanding job. Risks to worker safety, coupled with the increasing pressure to provide conserve costs while delivering quality, are making automation appealing, and efficiency necessary, when selecting bakery equipment. The following dough handling solutions offer balance worker safety with other necessities.

New Processing Equipment: September 2022

Energy efficiency, automation, and ensuring a robust return-on-investment have been top-of-mind for snack food and wholesale bakery companies in the market for ovens and proofers, according to companies that make those machines, who say sales have been strong.

New Packaging Equipment: September 2022

Bakery and snack plants are moving away from manual cartoning and case packing to automated equipment.

New Processing Equipment: August 2022

Snack food and wholesale bakery companies in the market for dough-handling equipment such as dividers, depositors, and rounders have been increasingly focused on machines that provide greater automation, along with the corollary efficiency and labor savings.

New Processing Equipment: May 2022

Snack food and wholesale bakery companies in the market for machines that help prepare, store, transport, and otherwise handle ingredients are most focused on qualities like automation, ease of maintenance, and the ability to deliver higher performance in throughput and accuracy.

New Processing Equipment: February 2022

Mixers serve essential functions for snack and bakery companies creating their own dough. We ask a lot of this category of heavy-duty equipment, including reliability and efficiency, to maintain established product quality-control standards.

New Packaging Equipment: February 2022

New and updated tray handing equipment that performs automated or semi-automated loading of bakery and snack products into trays and baskets, as well as handles bakery trays, baskets, and other reusable distribution containers for finished products, has grown increasingly sophisticated.

New Processing Equipment: January 2022

Higher capacities, new shapes, longer blade life, automation, flexibility, sanitary design, quick changeover, and gentler handling of fragile ingredients are among the top features and benefits that snack and bakery companies want from their slicing, cutting and portioning machinery.

New Packaging Equipment: September 2021

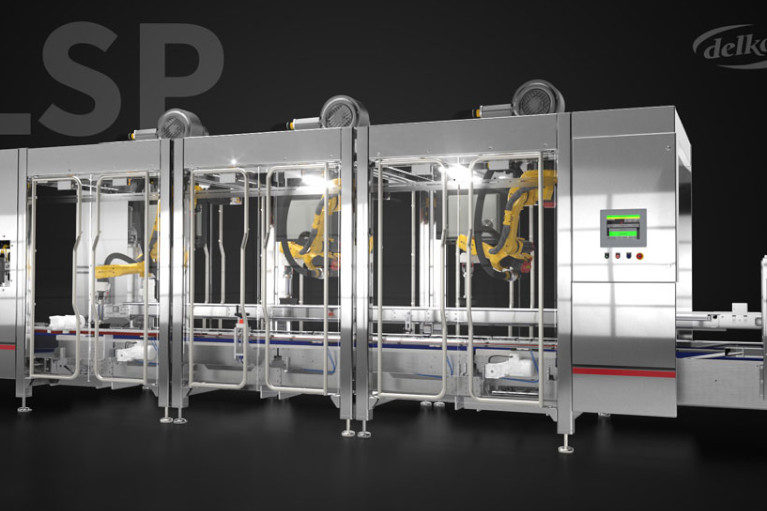

New robotic technology is helping to streamline and improve bakery and snack operations in both primary and secondary packaging applications. Areas of innovation include end-of-arm tooling (EOAT), sanitation, and space optimization. Gripper technology also is advancing to handle delicate products such as soft bakery items.

New Processing Equipment: August 2021

Snack food and wholesale bakery manufacturers in the market for dividers, depositors and rounders have a long list of considerations. These include automation, reliability, scalability, integration, flexibility, communication, customization, ease of maintenance and sanitation, and different packaging capabilities, according to companies that produce such machines.

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing