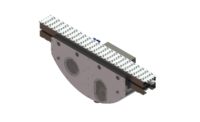

Transfer and diverter modules

Company: Hilmot, Milwaukee

Website: www.hilmot.com

Equipment Snapshot: Hilmot’s new MDR High Speed Electric Transfer (HCAT90) and Diverter (HCAT30) modules give users added flexibility in configuring their packaging or tote-handling applications by allowing 90° right turns and 30° diversions to their motorized drive roller conveyor systems. The HCAT90 Transfer is suitable for applications where a 90° right turn is needed, such as sortation, distribution or assembly. The HCAT30 Diverter provides a 30° angle to move packages and totes to a separate line. Both modules use three MDR conveyors to provide the rollers, belts and lifting motion, and are fully powered by 24-volt DC electricity for lower cost and quiet, efficient operation. Additionally, both modules are engineered to handle higher rates (40 products per minute for the HCAT90; 50 products per minute for the HCAT30). The HCAT90 features a low-profile frame for easy stacking of multilevel conveyor lines and is available in standard widths from 15–36 inches between frame, as well as in custom sizes. The HCAT30 can be located virtually anywhere along the conveyor line, according to the company, and also is available in standard widths from 15–36 inches between frame, as well as in custom sizes.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!