New packaging materials for convenient snacks and baked goods

courtesy of Zip-Pak

courtesy of Butler Automatic

courtesy of The Dow Chemical Co.

courtesy of DuPont Packaging & Industrial Polyers

courtesy of 3M, Industrial Adhesives & Tapes

courtesy of 3M, Industrial Adhesives & Tapes

courtesy of The Dow Chemical Co.

courtesy of DuPont Packaging & Industrial Polyers

Resealable, single-serve, lightweight packages are everywhere in the supply chain as manufacturers continue to develop thinner, yet more-durable, materials. For snack producers and bakers, packaging that extends product shelf life and provides consumer convenience in today’s grab-and-go world is important, too.

In fact, one of the biggest consumer demands cited by food manufacturers is for packaging that makes products last longer on the store shelf and at home. The latest packaging materials accomplish this by augmenting preservatives’ role in keeping food fresh. And they also are designed to keep products made with in-demand healthier ingredients at the freshness level that consumers expect.

“The trends we see are driven by consumer demands to serve an on-the-go lifestyle,” says Chris Graff, vice president of sales and marketing, Butler Automatic, Middleborough, MA. “Portability and portion control are important. This is driving demand for resealable, single-serve packages that enable eating on the go.”

Robert Hogan, director of global business development, Zip-Pak, an ITW Company, Manteno, IL, notes similar patterns. “We see a continuing trend toward convenience, whether it means adding a reseal feature to items such as salty snacks and sunflower seeds, or brand owners offering snack items in canisters that fit into automobile cup holders. We also see some consumer packaged goods moving from bag-in-box to flexible, resealable package formats,” he says.

Two trends are dominating the food industry, according to Gordon J. Galloway, director, sales and marketing, Elite Extrusion Technology, St. Charles, IL. The first is the move toward flexible pouches as a replacement for rigid containers. The second is the development of flexible packaging materials that extend shelf life, while reducing the cost of manufacturing the pouch.

Packaging innovations

Elite Extrusion Technology recently introduced Elite SL10 enhanced barrier polyethylene film, which is designed to extend the shelf life of baked goods and snacks. SL10’s oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) barriers are 40 percent better than standard polyethylene, according to the company, and can result in a 10-day or greater shelf-life increase. OTR is the rate at which oxygen gas permeates a film at specified conditions of temperature and relative humidity.

SEALUTION Peel Polymers from The Dow Chemical Co., Midland, MI, provide peel/seal packaging with easy-open functionality. The material reduces or eliminates tear stringing and requires less force for opening. “This allows greater seal integrity for improved product protection and recyclability,” says Apurva Shah, North America market manager for food and specialty packaging. “The polymers also feature tamper-resistant seal discoloration.”

ELITE AT polyethylene resins, also developed by Dow, offer consumers consistent, high-performance seal properties with attributes such as optics, stiffness, toughness and organoleptics (qualities that stimulate the senses). “They are a good option for a wide variety of vertical and horizontal form/fill/seal applications often used in bakery and snack food plants,” Shah adds.

DuPont Packaging & Industrial Polymers, Wilmington, DE, has been working on solutions related to convenience and freshness using materials that improve sustainability and performance, according to Yasmin Siddiqi, the company’s global packaging relationship manager.

For example, Bemis Co., Neenah, WI, recently developed a packaging solution using DuPont Selar PA and DuPont Bynel in a resealable package. The package comprises two individually sealed compartments, which provides added convenience by allowing the consumer to peel and reseal the package 20 times or more with fingertip pressure. The package is also perforated, which allows the consumer to separate the two compartments without using a knife or scissors.

Siddiqi notes that the packaging technology allows the individual compartments to be sealed separately, preserving freshness of the unused portion (until opening) and reducing food waste—all while creating differentiation at retail.

Zip-Pak has introduced a resealable matrix fastener called Vector. The fastener can be used in traditional resealable package formats or in two new package formats: Pour & Lok and Zip360. “We use a single strip of Vector, which seals to itself,” says Hogan. “Pour & Lok creates an effective pour spout, and Zip360 allows for a complete wide mouth opening of the pouch. We see great interest in these types of flexible formats.” The company also has introduced Zipbox, a packaging format that combines the best features of a carton and a flexible pouch.

Bundling products

3M, Industrial Adhesives & Tapes, St. Paul, MN, has introduced the Multipack Solution, which offers an improved way to bundle products. It consists of Scotch Clean Removal Multipack Tape and CEFMA tape-application machinery. The machinery applies the tape at 70 bundles per minute while using less energy than other bundling methods, such as shrink wrap.

The Scotch Multipack Tape holds products together but does not damage the primary packaging when the consumer removes it. The printed tape also enables improved branding and communication with consumers at the retail shelf.

“Manufacturers are looking for ways to improve their bundling capabilities,” says Jackson T. Shulman, U.S. packaging marketing supervisor, 3M. “It is easy to open the bundle, and the repositionable Multipack tape enables quick reorganization of products. Also, the configuration is less wasteful than traditional solutions.” On the production side, the Multipack Solution increases line efficiency, enhances the look of the product on the shelf, and lowers material and energy consumption, he adds.

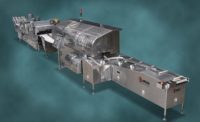

Butler Automatic manufactures automatic splicing technology designed to eliminate line downtime due to splicing a new web of film into the packaging process. “We work with a wide range of films, in a wide range of packaging equipment,” says Graff. “Recently, we’ve seen hybrid materials that combine characteristics of paper and polyethylene. These materials allow for some innovative package shapes that create impressive shelf presentations.

“As packages get smaller and line speeds increase,” Graff continues, “the complexity of web handling and the need for accurate film printing is increasing. The more-complex indexes, increased speeds and smaller sizes are putting demands on the technology. Food processors are demanding greater line efficiency and getting better at tracking it and investing in it. Manufacturers are responding to these demands.”

One challenge in designing packaging materials for bakery and snack food production involves balancing sustainability, cost and performance, while creating a multisensory experience for consumers, says Siddiqi.

A practical example of meeting these challenges is Ana’s Foods, Austin, TX, and IPL Inc., Saint-Damien, Quebec. The companies replaced rigid containers with the SkinnyPack, a flexible, rigid container that combines the advantages of thin, flexible film with the advantages of a strong, rigid frame. The lighter-weight, thin-walled SkinnyPack uses 54.8 percent less plastic than the original containers, says Siddiqi. “Also, the mono-material packaging structure allows the container to be 100 percent recyclable.” The product received top honors in the 2015 DuPont Awards for Packaging Innovation competition.

As manufacturers continue to push the envelope, bakers and snack producers can expect to see further innovations in packaging materials and formats that will help them address a host of perennial and new consumer requests, like extended product shelf life and ease of use.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!