The sustainability spectrum

The word sustainability, like “green,” “natural” and “eco-friendly,” covers a lot of ground. It may mean a product contains organic ingredients, has biodegradable packaging or saves energy in some way. It may also mean that a manufacturer donates a portion of its proceeds to a charitable cause, organization or community, or something else altogether. One thing’s for sure: Consumers want more foods that fall within the sustainability spectrum, and manufacturers are wise to consider moving to greener products to meet this demand.

Article index:

- Green shoppers

- Sustainable ingredients

- Packaging and shipping

- Challenges ahead

- Communication is key

- New horizons

Green shoppers

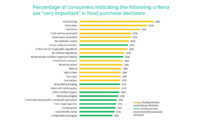

In 2009, the Grocery Manufacturers Association (GMA), Washington, enlisted Deloitte to examine shoppers’ purchasing behaviors when it came to sustainable products. The Chicago-based firm surveyed more than 6,000 shoppers exiting 11 major retail chain stores, and ultimately found green shoppers to be a valuable target for manufacturers. Not only did they purchase more items on every trip, but they also went on more trips than the average shopper. They were less price-sensitive and willing to spend more on a product they believed to be sustainable.

In fact, according to the survey, for most of the participants (green or otherwise), a product’s sustainability became a tie breaker when they perceived other major considerations like price and effectiveness to be equal. Because of this, the report says, sustainability characteristics drive a large amount of product switching. And once the switch is made, shoppers rarely look back.

Despite these encouraging findings, only 22% of shoppers’ trips included a green product, even though 99% indicated they were ready and willing to buy green. So what does this mean for snack manufacturers and bakers? “There are substantial gaps between the market’s readiness for sustainable products and the delivery of those products to the consumer,” the report says.

Sustainable ingredients

Bakers or snack companies looking to increase their “green value” or sustainability have a number of avenues to consider.

One way manufacturers often start infusing eco-friendly practices into their products is with more sustainable ingredients. Pete and Gerry’s Organic Eggs, Monroe, N.H., for instance, prioritizes sustainability starting at the ground level: Farming. The first Certified Humane egg farm in the country, and one that began as a small family business, Pete and Gerry’s abides by a cage-free, organic model that yields eggs from hens treated without antibiotics, hormones, pesticides, genetically modified organisms (GMOs) or animal byproducts. Once the company began to grow, it faced a crossroads that required it to choose between going the way of the factory farm or picking an alternate path.

“Our family has been farming for four generations, and rather than becoming yet another factory farm, we decided to grow our business by recruiting other small family farms to supply eggs with us,” says David Rachlin, Pete and Gerry’s executive vice president of marketing and business development. “All our farmers follow the strictest standards of humane animal treatment, safety and environmental sustainability.”

Beyond this, the company recognizes that small family farms provide something for eco-conscious clients and consumers that “big agriculture” can’t: “A vital economic and social movement,” Rachlin says, which can expand family farms’ reach without compromising their values. In this way, Pete and Gerry’s represents a sustainable model that not only appeases shoppers looking for eggs from humanely treated hens, but also provides opportunities for smaller scale farms to stay in business.

But these types of initiatives aren’t bound by America’s shorelines. Gelnex, Itá - Santa Catarina, Brazil, recently aligned itself with the Brazil-based Abrinq Foundation, an international nonprofit dedicated to promoting the rights of Brazil’s children and adolescents. “We make significant contributions to the health, education and well-being of the people in the communities in which we operate—with a strong emphasis on children,” says Felipe Chaluppe, president of In3gredients Inc., Chicago, and Gelnex’s U.S. representative. “This is especially important to us because there’s a real need for such assistance in some of the rural areas in which our plants are sited.” The company is committed to going beyond creating jobs to also improving schools, libraries, health services, elder care, infrastructure and recreation for a healthier future.

“We see more companies looking at sustainability from a supply-chain perspective,” states Megan Speas, director of marketing at Horizon Milling LLC, Wayzata, Minn., a joint venture under the Cargill umbrella. “Companies are looking more closely at both how they source ingredients and the sustainability of the source of ingredients.” As part of the Cargill Sustainable Cocoa Program, the company trains cocoa smallholders in Brazil, Cameroon, Côte d’Ivoire, Ghana, India and Vietnam to farm sustainably. As a result, some farmers are seeing a nearly 30% income improvement through better quality crops and higher yields.

Packaging and shipping

Once a product is made in a sustainable way, or if a switch to more sustainable ingredients isn’t possible, manufacturers might look to packaging to “up the green ante.”

“Regarding packaging, we’re seeing sustainable trends moving toward preserving food for a longer period of time,” explains Jeff Wooster, global sustainability leader for performance packaging at The Dow Chemical Co., Midland, Mich., who notes that more than 30% of the world’s food is wasted. “Food safety and freshness are key concerns in baked goods, so packages that reseal tightly are quite popular.”

One recent development is Dow’s 100% polyethylene stand-up pouch. While it still contains many layers, the pouch is made with only one basic type of raw material—polyethylene—so it’s easier to recycle where collection facilities exist. “The pouch offers up to 88% less total material weight, consumes 54% less total energy and allows for up to 90% less post-consumer solid waste compared to a bag-in-box cake mix,” says Wooster. “It’s also fully recyclable in the pre-consumption stage, or where there is a post-consumer collection chain, such as the ‘return-to-retail’ collection system used for PE shopping bags and films, providing less packaging waste.”

Once products are packaged, it’s time to ship them. Companies like Gelnex are working to develop sustainability initiatives that go beyond preserving gasoline. Gelnex recently announced a pallet-free shipping system that employs no wood or plastic pallets and is expected to save more than 40,000 trees in its first year. The program also conserves weight and energy and eliminates the costs and inconvenience of storing and disposing of pallets.

Challenges ahead

Yet sustainability isn’t a perfect process, and doesn’t come without its share of challenges. The most common challenge faced by bakers, snack manufacturers and ingredient suppliers is finding a balance that makes sense for a company and its goals.

“Achieving more sustainable operations is like balancing a scale,” Wooster points out. “Ideally, we strive to simultaneously increase performance and decrease resource consumption, but on occasion, these two goals can conflict.” For example, if a type of packaging uses fewer materials but it’s weak, then it might not be a sustainability initiative worth pursuing because the product’s performance is compromised.

“If the package fails because it has been simplified too much, the result is a decrease in overall sustainability performance because the product is wasted, despite the lower resource use for the packaging,” he continues. On the other hand, sometimes it takes a little more packaging in the form of single-serving packs to be sure that food isn’t wasted. Indeed, more materials are used, but in the end, the product hasn’t contributed to food waste.

Pete and Gerry’s has also had to find a balance in its decision to support more family farms—some of which are located farther away now that consumer demand for its eggs has exceeded the number of small farms in its market area. “This required us to bring on more small family farmers who are farther away from our home farm and our egg packaging facility than we would ideally like,” says Rachlin. On the other hand, it has enabled the company to stick to its core values and also challenged it to increase its logistical efficiencies.

Communication is key

The GMA survey cited earlier found that even though the most dedicated green consumers say they’ll pay more for a sustainable product, most people want such foods to be comparable in price to conventional options. “Shoppers don’t understand why a green product should cost more if it was manufactured with less packaging or it was transported less distance,” the report reads.

Deloitte recommends that retailers and manufacturers make a concerted effort to communicate the business case for buying their green foods. When done correctly, success isn’t far behind.

Dow, for example, recently participated in World Food Day by creating educational materials to demonstrate how packaging can help extend food’s shelf life and protect food during its farm-to-table journey. “Our interactive content showcased how protective films can help preserve food longer to extend shelf-life and delay spoilage,” explains Wooster, “allowing more consumers to have access to fresh foods with less of it going to waste.”

And Pete and Gerry’s Rachlin advises, “Start by asking yourself why you want to operate more sustainably and make sure you communicate that to your customers and consumers, so that they will understand and value what you’re doing.”

|

New horizons in sustainability Barry Callebaut AG, Zurich, has issued an annual report on its sustainability practices that highlights the company’s commitment to creating a sustainable cocoa supply chain. Among these practices is the company’s Cocoa Horizons sustainability initiative, which provides training; aims to improve crop yields, farmer income and farmer livelihoods; and details the company’s strategy in the areas of sustainable cocoa, environmental protection and employee development. “With a growing global demand for chocolate, a sustainable cocoa supply chain is vital for long-term business growth,” says CEO Juergen Steinemann. “In order to ensure sufficient cocoa production for years to come, we have embedded sustainability into our corporate strategy.” The report identifies three key challenges to sustainable cocoa farming: The need for farmer training in good agricultural practices to improve crop productivity and farmer income; a lack of adequate plant materials, fertilizers and pesticides available to farmers; and insufficient farmer access to funds to invest in pesticides, fertilizers and yield-enhancing practices. To address the gaps in knowledge, materials and funding, the report documents the various elements of Cocoa Horizons. Established in 2012, the program is built on three key pillars to improve cocoa sustainability: Farmer practices; farmer education; and farmer health. Improving farmer practices through training is at the heart of Cocoa Horizons. Barry Callebaut believes farmer training leads to better agricultural practices, which lead to more productive cocoa trees, higher yields, increased farmer incomes and, ultimately, better livelihood for farmers, the company reports. The report highlights the opening of a new Cocoa Center of Excellence in Pacobo, Côte d’Ivoire, to equip farmers with practical know-how. The center, which opened in July 2013, provides training in good agricultural practices, post-harvest management techniques, optimal use of inputs, crop diversification, farm rehabilitation and grafting, and basic business skills. Approximately 300 managers of cocoa cooperatives will receive training during the center’s first year of operation. Once qualified, those farmers will share knowledge with two additional Barry Callebaut farmer academies, then 12 model farms and eventually 575 field schools across the Côte d’Ivoire Farmer education and health are also major parts of the program. Along with farmer training, Cocoa Horizons has community programs that improve access to primary education for children of farm workers in Côte d’Ivoire, Ghana, Cameroon and Brazil. These programs provide cocoa curriculum; contribute to educational infrastructure; and support literacy, life skills and vocational training. Cocoa Horizons also addresses basic health needs of farmers in remote cocoa farming regions. Barry Callebaut works with its partner cooperatives and the communities themselves to provide access to potable water. “Now more than ever, our customers are interested in products with a certain level of social and environmental assurance,” says Dave Johnson, president and CEO of Barry Callebaut Region Americas. “Our sustainability initiatives allow us to be a leading supplier of sustainable as well as certified cocoa and chocolate products. From sourcing and processing cocoa beans to manufacturing the highest quality chocolate, Barry Callebaut remains committed to improving sustainability along the entire cocoa supply chain.” The report also presents the company’s sustainability strategy for environmental protection and employee development. Barry Callebaut says it makes concerted efforts to minimize its environmental impact in the areas of production and transportation, which account for the majority of its environmental footprint. It also uses standards and methodologies for measuring and reporting impacts, such as the Greenhouse Gas Protocol and the Global Reporting Initiative. The complete report, which includes videos assets, can be found at http://annual-report-2012-13.barry-callebaut.com/#sustainability. |

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!