Getting bullish on production

When challenged by its parent company to quadruple its output, El Matador Enterprises decided to invest in more efficient processing equipment to achieve this goal. Among its purchases was a new conveyor system that has enabled the Michigan-based tortilla chip manufacturer to significantly reduce its downtime and increase its production yields.

When El Matador Enterprises was founded in Grand Rapids, Mich., in 1976 by Miguel and Isabel Navarro, its premium-quality, corn tortilla chips were made using an authentic Mexican recipe that had been passed down through generations: Fresh-cooked corn was ground into masa using Mexican lava stones before further processing and seasoning.

While the process hasn’t changed in more than 35 years, production of El Matador’s chips has skyrocketed since 2007, when the company was purchased by Garden Fresh Gourmet, a Ferndale, Mich.-based manufacturer of chips, salsa, dips and hummus. The purchase added 16 private-label stock-keeping units (SKUs) to El Matador’s existing eight SKUs, and consumer demand for its natural, authentic-tasting chips rose steadily.

During a five-year period, El Matador was challenged to quadruple its output to meet demand, so the company opted to invest in more efficient processing equipment.

“We know our process takes longer compared with new technologies in tortilla chip making,” says Mike McClellan, director of operations. “But our quality is better, and you can taste it in the product. Fortunately, our new parent company has the same commitment to quality ingredients and hand-made batches. Price-wise, we still need to be competitive, though, so we seek ways to increase efficiencies without sacrificing our products’ integrity.”

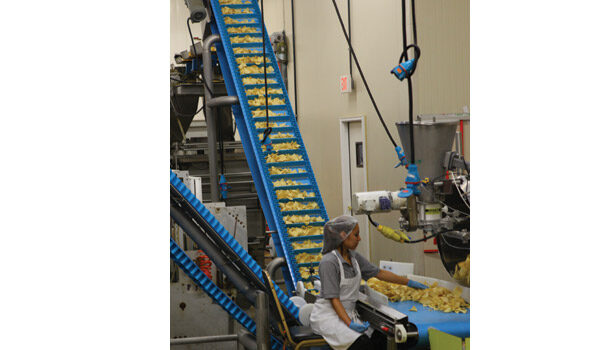

Recent upgrades to the company’s 60,000-sq.-ft. manufacturing facility include tumblers, a new fryer, coders, a toaster oven and new corn-cooking tubs. The most significant efficiencies have come from the design and installation of a washdown conveyor, the Walker Original Washdown system or W.O.W. from Walker Custom Sheet Metal. The company designs and fabricates custom sheet metal for a variety of industries and needs, and offers food-grade hoppers, chutes, conveyors and industrial machine guards, dust collectors, platforms and more.

The design of the conveyor is ultra-sanitary and tool-less, which saves production time and costs. El Matador ended up installing eight of them, so it was a relatively quick solution to its challenges, according to Jim Monaweck, project manager at Walker Custom Sheet Metal, and designer of the conveyor’s patent-pending bearings.

Eliminating downtime

Now, production no longer has to be halted when diverting product, eliminating one area of downtime. Bill Stanley, El Matador’s maintenance manager, estimates that downtime has decreased by 25-30%, so the company is seeing significant savings.

Sanitation downtime has also improved. Due to the conveyor’s tool-less design, the sanitation team performs 100% of the conveyor disassembly and reassembly without mechanical staff assistance. Disassembly also takes less than 10 minutes.

“The new conveyors are essentially maintenance-free,” says Bill Mourer, sanitation manager, who has seen cleaning time reduced by 20% and an overall reduction in food-safety risk. “The open, cantilever style makes taking the belts off and reinstalling a lot easier. With the unique bearings, we are able to clean and sanitize areas around the bearings and pulley shafts that we could never clean before. Preset tensioners mean no more wrenches and no tracking issues. The tubular design of the stainless-steel frames make cleaning easier, and the large casters make moving it to a wash area easy. Manufacturers with lean programs would [like] these features.”

More output, move savings

These improvements have increased El Matador’s production yields from 83% to 92%, and overall production efficiencies have risen nearly 10%. “The new conveyors have improved our time,” says Nick Coronado, first-shift operations manager. “We simply get the job done faster and with less waste.”

Coronado also notices a cost savings through the type of conveyor belting used because significant seasoning isn’t lost in the chip transfer. Now, the seasoning is carried through to the bags, and the chips experience less breakage, a major quality improvement. Product quality has also improved through the addition of climate controls in the manufacturing facility, separating El Matador’s production from its packaging line.

Still, El Matador had to add another production shift to keep up with demand. “We’ve been able to increase output fourfold, but our employee count hasn’t had that same dramatic increase,” says McClellan. “That kind of improvement doesn’t happen without a team effort. We now have a staff of 51, and each individual has been absolutely critical to our growth.”

When asked about plans for the future growth of El Matador, McClellan hinted at new projects in the pipeline, saying that the company is always looking to grow and expand. Being a part of Garden Fresh Gourmet continues to create opportunities for complementary products and expanded distribution for El Matador, a West Michigan icon that now also reaches international customers through its private-label brands.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!