Equipment

Topics

Depositors, Dividers & Rounders

Extruders

Fryers

Mixers

Ovens & Proofers

Packaging

Slicing, Cutting & Portioning

Warehouse & Distribution

Inspection & Detection

ARTICLES

WeighPack debuts bulk weigh filling machine

GEA offers preassembled modules for ovens

Puffed and extruded snacks shaped by innovation: Clextral

Slicing and portioning equipment must offer efficiency, sanitation

Piab Robotic Gripping Division moves to Fairborn, OH

Consistency is key with seasoning and coating equipment

Grote Company acquires conveyor manufacturer ProFab

Cablevey Conveyors launches automated food conveyor cleaning system

Meritech evolves its automated handwashing stations

Snack-focused webinar to tackle trends and tech

Douglas J. Peckenpaugh

Douglas J. Peckenpaugh is Group Publisher of Snack Food & Wholesale Bakery, Dairy Foods, The National Provisioner, and Packaging Strategies for BNP Media. He has nearly three decades of publishing experience following the food industry from farm to fork, covering agriculture, ingredient processing, retail grocery branding, foodservice menu development, and food product R&D and manufacturing. He serves in leadership roles at his local suburban Chicago food pantry and church. Doug studied Professional and Creative Writing at Purdue University.

Jenni Spinner

Jenni Spinner is the chief editor of Snack Food and Wholesale with more than 25 years of experience in business-to-business communications. She has written extensively about food production, safety and packaging; pharmaceutical drug development; concrete and masonry construction; and more. She holds a Bachelor’s in Communications from the University of Illinois. Jenni can be reached at spinnerj@bnpmedia.com.

IMAGE GALLERIES

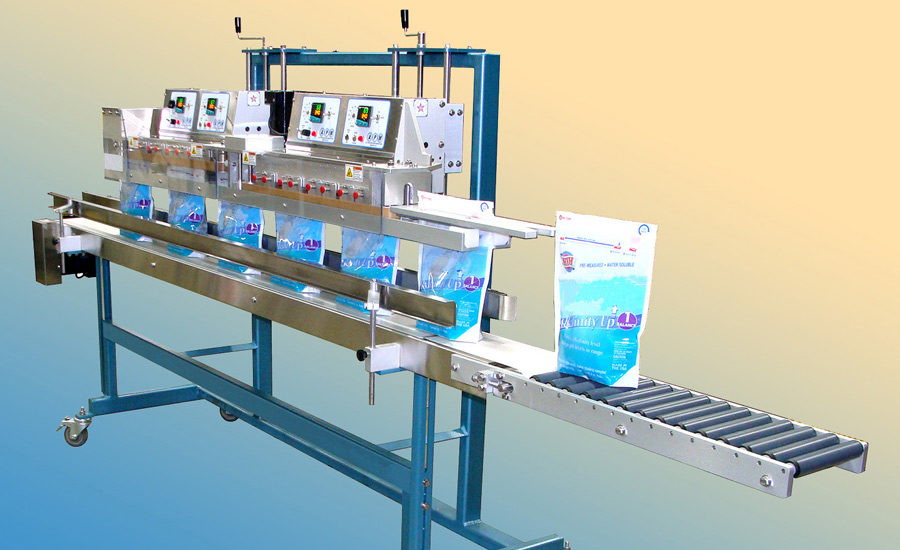

New Packaging Equipment: August 2020

The nature of snack and bakery operations poses challenges to manufacturers of robotics equipment. Space is an issue. Also, the equipment must be able to handle a wide range of products of different shapes and sizes at high speeds while not damaging the goods.

New Processing Equipment: May 2020

Snack and bakery customers in the market for dough-handling equipment like dividers, depositors, and rounders are looking for versatility, greater precision, higher capacity, longer maintenance intervals, adjustability of qualities like width and weight, and machines that can handle natural, clean-label, and gluten-free products.

New Packaging Equipment: May 2020

A desire for sustainability is one of the key factors driving the latest packaging innovations in baggers, closing equipment, twist ties, clips, zippers, resealable materials, heat sealing, and ultrasonic sealing.

New Packaging Equipment: April 2020

Manufacturers and researchers worldwide are striving to develop new ways to keep snack and bakery products safe and fresh over the course of their intended shelf life.

New Processing Equipment: April 2020

Flexibility, greater sanitation, gentle handling of ingredients, quicker changeovers, more precise weight control, and the ability to make products with healthier ingredients are top of mind features and benefits for snack and bakery customers of extrusion equipment and technology.

New Processing Equipment: February 2020

Customers of ingredient handling equipment are focused on a wide mix of factors to come up with their optimal formulation. These include accuracy, traceability, food safety, automation, cleanability, efficiency, flexibility, batch quality and fire safety, manufacturers say.

New Packaging Equipment: February 2020

The latest product handling equipment, cartoners, case erectors and packers, loaders and palletizers, features maximum flexibility in terms of product handling and packaging styles, which is good news for bakery and snack producers.

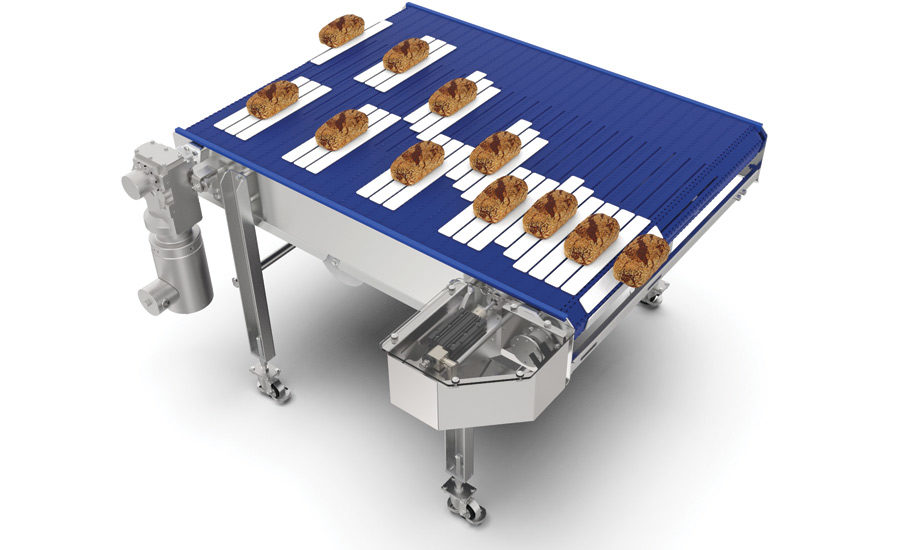

New Processing Equipment: January 2020

Snack and bakery industry customers want belts and conveyors that are fast and easy to clean, maximize energy efficiency, offer strength and durability, require as few tools as possible, and provide flexibility to either switch out products and/or run multiple products at once.

New Packaging Equipment: January 2020

X-ray, metal detection, checkweighing and vision systems continue to advance, offering bakery and snack producers many ways to improve their quality control programs.

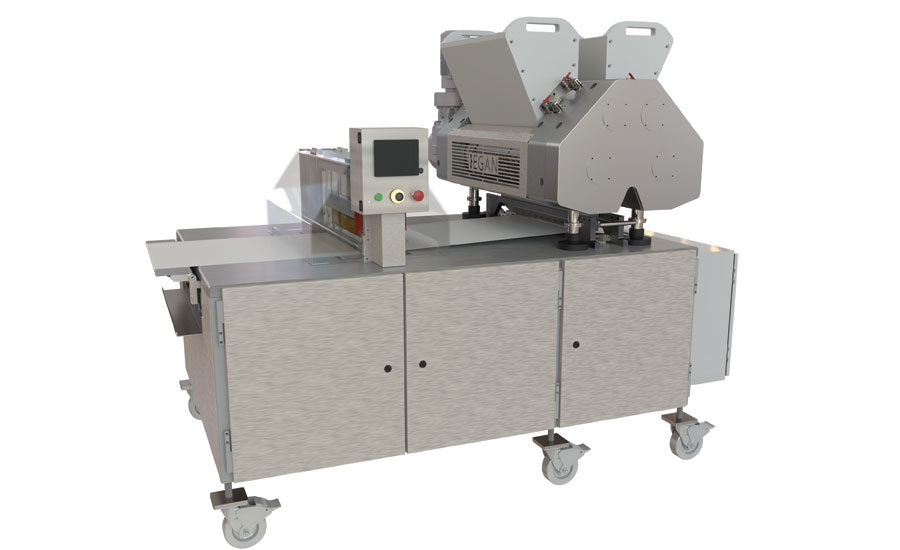

New Processing Equipment: November 2019

Different shapes, quicker changeovers, better sanitation, a smaller footprint, more automation, and a balance of speed and safety are among the top-of-mind criteria for customers of slicing and cutting machines in the snack and bakery industry, according to machine manufacturers.

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing