Photo Galleries

New Packaging Equipment: August 2020

The nature of snack and bakery operations poses challenges to manufacturers of robotics equipment. Space is an issue. Also, the equipment must be able to handle a wide range of products of different shapes and sizes at high speeds while not damaging the goods.

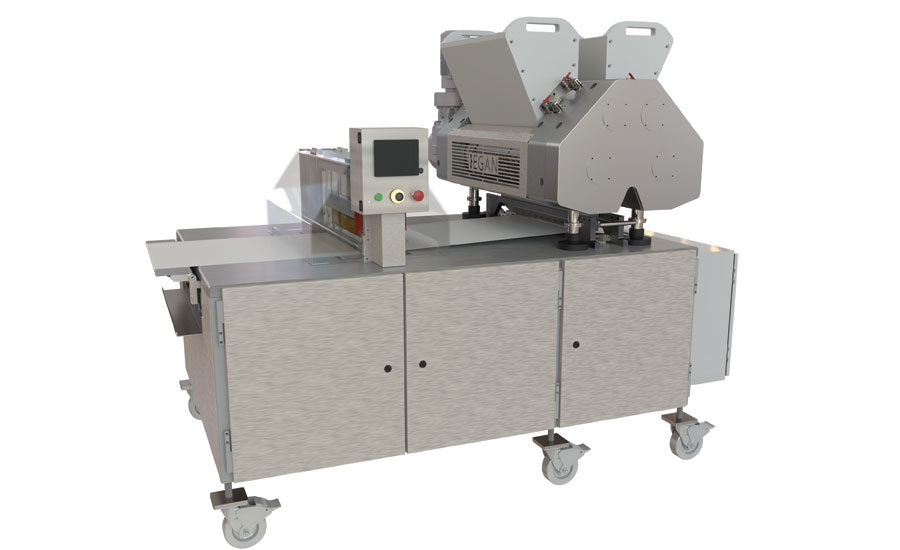

New Processing Equipment: May 2020

Snack and bakery customers in the market for dough-handling equipment like dividers, depositors, and rounders are looking for versatility, greater precision, higher capacity, longer maintenance intervals, adjustability of qualities like width and weight, and machines that can handle natural, clean-label, and gluten-free products.

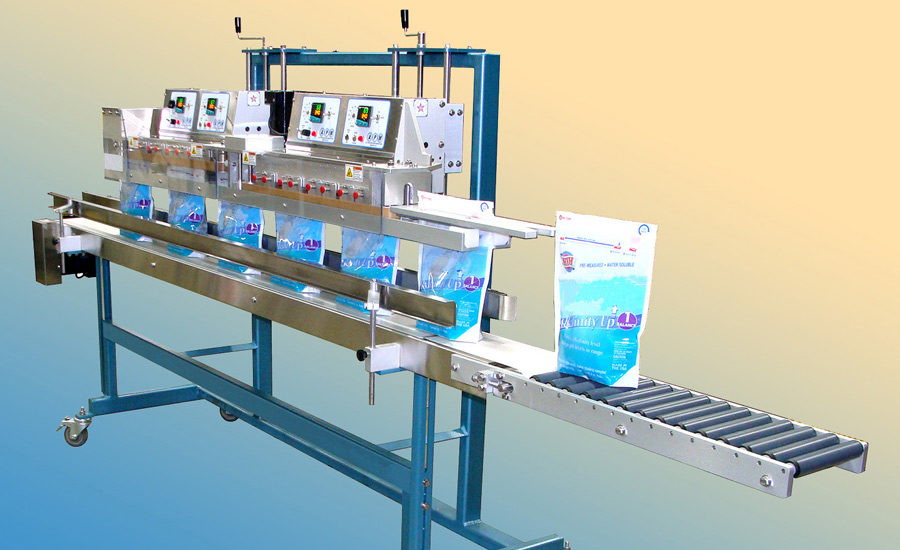

New Packaging Equipment: May 2020

A desire for sustainability is one of the key factors driving the latest packaging innovations in baggers, closing equipment, twist ties, clips, zippers, resealable materials, heat sealing, and ultrasonic sealing.

New Packaging Equipment: April 2020

Manufacturers and researchers worldwide are striving to develop new ways to keep snack and bakery products safe and fresh over the course of their intended shelf life.

New Processing Equipment: April 2020

Flexibility, greater sanitation, gentle handling of ingredients, quicker changeovers, more precise weight control, and the ability to make products with healthier ingredients are top of mind features and benefits for snack and bakery customers of extrusion equipment and technology.

New Processing Equipment: February 2020

Customers of ingredient handling equipment are focused on a wide mix of factors to come up with their optimal formulation. These include accuracy, traceability, food safety, automation, cleanability, efficiency, flexibility, batch quality and fire safety, manufacturers say.

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing