Photo Galleries

New Packaging Equipment: February 2020

The latest product handling equipment, cartoners, case erectors and packers, loaders and palletizers, features maximum flexibility in terms of product handling and packaging styles, which is good news for bakery and snack producers.

New Processing Equipment: January 2020

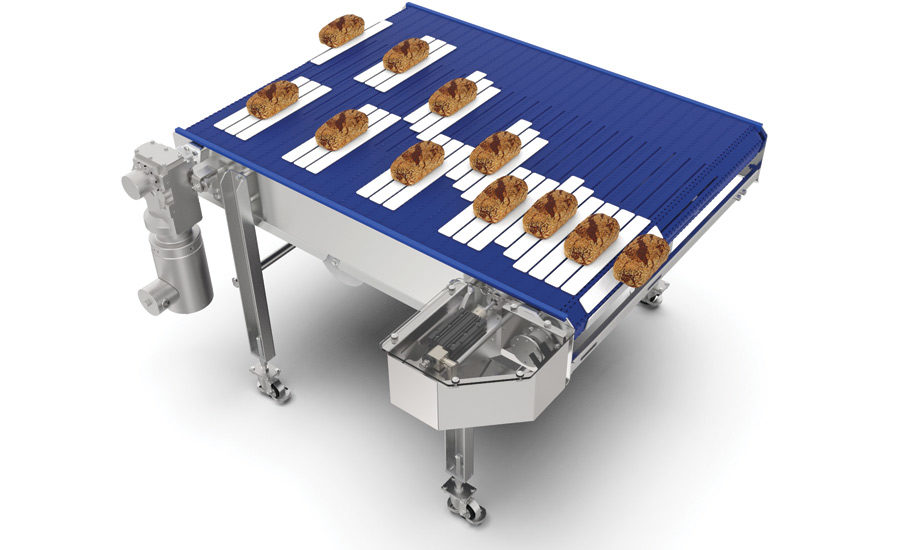

Snack and bakery industry customers want belts and conveyors that are fast and easy to clean, maximize energy efficiency, offer strength and durability, require as few tools as possible, and provide flexibility to either switch out products and/or run multiple products at once.

New Packaging Equipment: January 2020

X-ray, metal detection, checkweighing and vision systems continue to advance, offering bakery and snack producers many ways to improve their quality control programs.

New Processing Equipment: November 2019

Different shapes, quicker changeovers, better sanitation, a smaller footprint, more automation, and a balance of speed and safety are among the top-of-mind criteria for customers of slicing and cutting machines in the snack and bakery industry, according to machine manufacturers.

New Packaging Equipment: November 2019

Today’s form/fill/seal (FFS) systems accommodate a wide range of packaging options at high speeds, and provide packaging formats that bring convenience to shoppers. In effect, they have evolved to enable manufacturers to respond to market changes in package size and format.

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing