Snack and bakery producers seek new printers amid a competitive marketplace

New technology produces labels on-demand with more precision at higher speeds

courtesy of Afinia Labels

courtesy of Afinia Labels

courtesy of Linx Printing Technologies Ltd.

courtesy of Epson

courtesy of Brother Mobile Solutions

courtesy of Primera

courtesy of Primera

Snack producers and bakeries are facing a competitive marketplace inhabited by more brand designs and increased variation in packaging. Brand extensions focused on more flavors, seasonal offerings and promotions need to happen at a faster pace. Nutrition Facts panels have seen a makeover. All of this translates into a need for streamlining label creation.

“New FDA labeling regulations require closer attention to ingredients and nutritional tables. In many cases, this is the impetus for brands to revisit their labels and consider redesigns,” says Jan DeRoeck, director, solutions management, Esko USA, Miamisburg, OH.

Two major labeling trends are increased demand for variable imaging and unique die/label shapes, according to Darrell Friesen, president and CEO, Jet Label & Packaging, Edmonton, Alberta. “Variable imaging allows for discrepancies in images and text on labels, opening the door to micro-runs that, for customers, provide the feel of customization. Unique label shapes can help create a stand-out look for products in a competitive space.”

Snack and bakery continue to experience product proliferation and diversification, leading to smaller batch sizes and more variability among brand offerings, notes James Wolff, vertical marketing manager, Videojet Technologies, Chicago. As a result, he sees more producers shifting from pre-printed labels and packaging to variable printing directly on the package.

New printing technology

Variable information printers such as continuous ink jet (CIJ), thermal inkjet (TIJ), thermal transfer overprinters (TTO) and laser printers have the flexibility to provide detailed product information, “use by” dates, and traceability data as part of the label, according to Carole Perry, marketing specialist, Linx Printing Technologies Ltd., Saint Ives, England. “Lasers can code at up to 2,100 characters per second with no compromise on code quality even on hard-to-mark label substrates. For example, light-sensitive labels can be laser-coded at very high speeds, delivering detailed information with a quality print.”

CIJ printers can print up to five lines of date and batch code information, along with barcodes and logos, Perry adds. “Some TIJ and CIJ printers can code onto both primary and secondary packaging, providing a flexible coding solution for less-intensive lines. CIJ can code in any orientation without any impact on code quality, providing the flexibility to place the code exactly where it is needed on the label.”

One of the biggest innovations in label printing is the advent of high-speed inkjet, notes Mike Atkins, national sales manager, Afinia Label, North America, Chanhassen, MN. “For example, Northstar and Sirius engines from Memjet, San Diego, provide photo-quality, full-color printing at high speeds. This allows for the entire label to be printed at once, on-demand. Prior to high-speed inkjet, companies had little choice other than to manage a large inventory of pre-printed labels to use in low-resolution, single-color thermal printers to add SKU-specific data.”

New label printing systems enhance product appeal and better communicate information on food content. With digital printing, the high quality allows for a smaller font and more information, while maintaining the legibility of the text. “Multi-layered labels and printing on the adhesive side are becoming popular to create more brand awareness and to promote customer interaction. Multi-layered labels are ideal for adding point-of-purchase coupons,” Friesen says.

Software adds capabilities

Product developers can design and enhance graphics for branding, create bar codes and gather food content all on one label, thanks to the addition of label-creation software such as Bar Tender and Wasatch Soft Rip from Epson America Inc., Long Beach, CA. Information on allergens and nutritional data is easily identifiable on labels, helping users meet compliance requirements. “The ColorWorks C7500G on-demand inkjet label printer with Wasatch SoftRIP makes it easy to spot color match and produce the same exact labels over time,” says Andrew Moore, product manager.

As consumers demand more visibility into the origin and content of their food, especially allergens, the key to communicating product information is flexibility in label production. “By printing variable data on-demand with TTO, whether on a label or directly onto the packaging, bakery/snack producers can meet these demands while minimizing the extent and damage of recalls and limiting rework. Corrections to misidentified ingredients or other content can be quickly executed without stopping production lines,” Wolff says.

On-demand color printing of labels continues to be a key market driver and is no longer limited to one type of customer. “Bakery/snack producers of all sizes have benefited from bringing their product labeling needs in-house. The ability to fully control the shape, size, color, quantity and material of product labels allows these companies to completely own their image,” says Geena Maharaj, global product manager, Primera Technology Inc., Minneapolis.

For example, Primera Technology recently introduced the LX500 Color Label Printer, which features a tri-color ink cartridge that keeps cost per label low, Maharaj says. High print speeds and a guillotine-style cutter allow users to quickly print and cut short-run labels. Printer drivers are included for Windows 7/8/10, along with Bartender Ultralite Software (for Windows) to format label designs, and add barcodes and QR codes. Typical applications include product labels for bakery, confectionary and other foods.

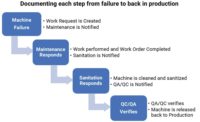

More producers are using new software to customize packaging, reduce downtime and minimize rework. For example, the latest TTO advance from Videojet is iAssure code quality assurance technology. “Standard on Videojet 6530 and 6330 TTO printers, iAssure captures an image of the print and uses algorithms to check the printed image against the intended image in real time. It is designed to reduce waste and rework time by catching print defects automatically,” Wolff says.

One recent development in labeling software is Powerforms from NiceLabel Americas, Milwaukee, according to Atkins. “It allows companies to create custom, kiosk-styled applications to simplify printing on-demand, and the software requires no knowledge of coding. The interface can be run from a touchscreen with intuitive drop-down menus to customize label content quickly and accurately at the point of packaging or sale.”

Over the past few years, developments in software specific to label creation and printing have been significant, according to Mike Lowey, retail industry specialist, Brother Mobile Solutions, Westminster, CO. “We make our mobile and desktop label printers smarter, more versatile and more responsive to user needs through software integration and apps.” The company’s printers are interoperable with major operating systems—e.g., Windows, Google, iOS—while Apple AirPrint and MFi certification make it easy to print directly using Apple iPhones, tablets and PCs without the need for additional downloads.

Meeting challenges

Maharaj sees two challenges in the snack and bakery realm: order simplification and application. “For the former, bakery/snack producers often have a wide variety of SKUs, where ordering labels for certain SKUs can be difficult in terms of order quantity. By bringing label printing in-house, companies can manage change and avoid waste caused by skewed forecasting.” She notes on-demand mobile printers are also helpful for labeling incoming supplies, as well as for labeling products, storage bins and other equipment used in facilities.

The biggest challenge for producers involves understanding the ideal time to apply labels—before or after the package is filled with product, according to Friesen. “Choosing a label material that enhances the package’s appearance is another challenge. There are many great-looking options out there for label materials, such as clear and metallic stock, and Kraft paper.”

What technological advances should we expect in the near future? Perry says very recent developments include the introduction of CIJ printers with self-service modules, which enable printers to be serviced without the need for an engineer call-out, helping to reduce downtime.

DeRoeck says more brands will use print-to-connect labels with online content, using tools such as augmented reality, QR codes and gamification—integrating game mechanics to motivate brand engagement.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!