Festida Foods pursues quality

A recent investment in a larger facility and state-of-the-art equipment has readied the company for future growth.

In a few weeks, people throughout the U.S. will celebrate Cinco de Mayo at home and at restaurants. They’ll be eating traditional Hispanic foods, sipping margaritas and snacking on tortilla chips and salsa.

In the Midwest, many consumers will unknowingly be enjoying tortilla chips made by Festida Foods Inc., a comanufacturer and copacker in Grand Rapids, Mich. The company makes private-label tortilla chips for retailers and wholesalers, as well as produces Festida brand tortilla chips and chip grinds (for use as ingredients and meal components) for foodservice customers, such as schools and restaurants.

Festida Foods was founded in 1989 in Cedar Springs, Mich., by Cuban immigrant Raul Vega and several other investors to “fulfill a need in west Michigan,” says current Festida Foods CEO and president Kyle Curtiss.

“As tortilla chips and Mexican food in general were increasing in popularity, there wasn’t a consistent local supply for them,” he says. “They noticed this niche and created a company to fulfill it. They started out making tortilla chips and corn chips and produced a little bit of everything, meaning they made the Festida brand, sold to distributors, produced private-label products for stores and all kinds of tortilla chips for any customer they could.”

About nine years ago, Curtiss and an investment group purchased the company from the principal owner Vega. “We then had a plan in place and six years ago this May, my wife, Jackie, and I bought it outright,” Curtiss explains.

Since then, Curtiss has pared down Festida Foods’ offerings to tortilla chips and corn chips and renewed the company’s focus on being a comanufacturer, copacker and private-label manufacturer. “That’s what we do best,” he says. “The science and art of making chips is really our specialty. We want to be a company that our customers come to and say, ‘Hey, we want a chip that looks and tastes like this, and we want it to be this color and shape.’ That’s what we get the biggest kick out of—developing a product that a customer describes to us.”

Developing new markets, however, is not part of the company’s forte, Curtiss acknowledges. “By and large, our objective is to make really good products for other people who know how to sell it,” he says. “We don’t have the marketing muscle. Historically, we haven’t been a sales-oriented company. We absolutely relish the job of combining science and art to create the best product we can.”

Still, not having “marketing muscle” hasn’t slowed the expansion of Festida Foods’ market. The company currently ships its products to customers in nine Midwest states and on the East Coast. Curtiss adds that, depending on the product, a few national accounts could potentially lead to shipments throughout the country.

Festida for years to come

With that future growth in mind, Festida Foods purchased a 150,000-sq.-ft. space in Grand Rapids’ Union Station Industrial Park in August 2011. The company currently occupies approximately 65,000 sq. ft. and subleases some of the remaining space. “Some of this is available to us anytime we’re ready to put an opening in the dividing wall and move in next door,” Curtiss says. “In Cedar Springs, we operated out of about 35,000 sq. ft., which means we have almost doubled our square footage. In the last two years, we have also doubled our sales and more than doubled our workforce. We’re up to around 65 employees now.

“We’ve invested in Festida for the years to come. The equipment is like a building block. We can continue to add scales and baggers and push our capacity. The equipment investment was a large, initial one that will serve us for years to come.”

Two other areas in the new facility that will continue to serve Festida Foods and its customers in the future are an analytical laboratory and a research and development laboratory. “We do all of our R&D here,” says Curtiss. “If we can get a customer to visit our plant, we greatly appreciate that opportunity because, number one, we have an outstanding facility and, number two, we can think and work on-the-fly, meaning we can make any adjustments they want during the process.”

Curtiss reiterates how much his team enjoys developing products that meet customers’ specific requirements. “That’s what we love to do best—to build somebody’s dream chip,” he says. “They’re never perfect—there’s no such thing as perfection. Every one of those chips is a snowflake, with its individual personality. Perfection is hard to find, but that doesn’t mean you can’t pursue it.”

Making the tortillas

Of course, having the right processes and equipment in place can make the pursuit of perfection easier, as Snack Food & Wholesale Bakery’s recent facility tour with Festida Foods’ director of operations Dave Ebels demonstrated.

The tour began with a walk-through of a large storage area filled with seasonings, salt and other ingredients adjacent to the warehouse. An automatic overhead door allows entry to an 8000-sq.-ft. washdown processing room.

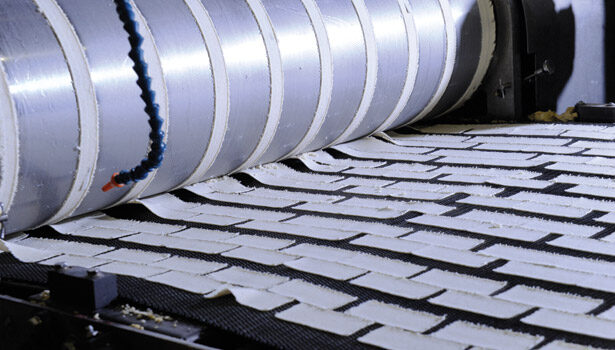

Pallets stacked with 50-lb. bags of flour—white, yellow and blue corn as well as specialty corns—are positioned at the end of two production lines: An older, larger line brought in from the Cedar Springs location can handle 2,000 lb. per hour; and a slightly smaller line is capable of producing 1,500 lb. per hour of finished product.

Both lines run 10-12 hour shifts, four to six days a week, depending on order volume. “January is our busiest month of the year,” says Curtiss. “We set a sales record in January. It’s driven by college bowl games and the National Football League playoff games and culminates with the Super Bowl. During January, six days a week and 24 hours a day were the norm for our operation.”

On the day of Snack Food & Wholesale Bakery’s visit, one line was producing white tortilla strips for an East Coast client, while the other was producing traditional, yellow corn tortilla chips for a Midwest customer.

Each process begins with the operator consulting a recipe from Festida Foods’ quality assurance and food safety director Michael Warren, a certified baker. “The night before, a packet of control documents is generated, says Ebels. “Just before to the start of the shift, the information is distributed among the line leaders, operators and other key players on the production floor.”

Referring to the recipe, each operator blends the necessary flours in the hopper, which delivers the raw materials to the mixer. Water and minor ingredients are also added at this stage of the process.

“From this point, the raw masa begins its journey through a series of processes,” explains Ebels. “First, the masa is cut into the desired shape, toasted and conveyed to the fryer. The entire process takes only minutes.”

After frying, the product is gently conveyed to a state-of-the-art, multi-lane distribution system. Using sensors, calculations are made to determine flow rates and how quickly the product moves downstream toward final packaging. Also located in the processing room is an oil-spray applicator that lightly sprays products destined for seasoning. This allows for a uniform coverage of topical flavorings.

On to packaging

Once they leave the cooking room, the chips travel into the packaging area. Chips are metered through revolution gates and distributed to four seasoning/weighing/bag making stations. On-machine seasoning applicators apply topical flavor just prior to packaging.

Festida Foods stores the product in its 30,000 sq. ft. warehouse. “A comprehensive warehouse-management and FIFO [first-in, first-out] program ensures product freshness, accurate counts and on time delivery to our customers,” Ebels says.

The company uses five of its seven bays for pickups. The remaining two are used to collect recyclable corrugated and other waste.

Keeping it clean

While much of Festida Foods’ processing equipment is designed to help facilitate cleaning, it still requires thorough daily cleaning. Sanitation manager Rob Goodin oversees the company’s sanitation programs and procedures, implementing Sanitation Standard Operating Procedures (SSOP) forms to direct personnel in the proper cleaning and sanitizing of all of the production areas and equipment.

A typical cleanup takes three to four hours, while an allergen cleaning usually takes six hours.

“In the last 10 years, [government] food safety and quality requirements for the food industry have more than doubled,” says Warren. “The Food Safety Modernization Act (FSMA) and other food safety standards are requiring the food industry to more finely detail its efforts to control safety and quality of the foods produced and sold in the U.S. To continue ensuring that the consumer is receiving safe and quality foods, we as manufacturers are accountable for identifying and controlling risks that can potentially reach the consumer of the foods we make. These laws and standards are helping us invigorate our methods and processes to maintain food safety and quality.”

Warren explains that Festida Foods is pursuing British Retail Consortium (BRC) certification and submits a Hazard Analysis and Critical Control Points-driven, Good Manufacturing Practice (GMP) audit to all its buyers. “While that’s not exactly a certification, it does verify to our buyers and customers that we have been audited by a third party and that industry standards and legal requirements are being met,” he says. “BRC certification will bring us an even higher level of assurance to our customers and consumers and help us pursue ever higher standards of quality.”

Curtiss adds that Festida Foods is also audited by retailers and wholesalers. “We have an open-door policy when it comes to that,” he says.

Leaving the landfill behind

When it comes to food-processing facilities, sanitation and sustainability often have a symbiotic relationship. After all, food waste can result in unsanitary conditions, which can attract a variety of pests.

Warren says the company continuously looks for ways to dispose of all of its waste in an earth-friendly manner, even the food waste. “Typically, all waste gets disposed of in the landfill or an incinerator, but that’s wasteful, if not inefficient,” he explains. “We found that some of the food not fit for sale could be recycled by using it as farm feed. A local farmer now picks up our food waste on a daily basis. We’ve eliminated our food waste by 100%.”

Festida Foods’ sustainability efforts extend beyond its food waste. According to plant services manager Bob Robbins, the company is “evaluating energy-savings and Energy Star programs. Currently, we utilize a recycling program in which we separate out corrugated as well as foam core, plastic wrap, bandings and food waste. We have reduced the total amount of items going to the landfill or incinerator by 57%.”

Festida means family

While the new facility offers its employees a modern, safe, amenity-filled environment in which to work, the company’s management team strives each day to deliver on a pledge displayed prominently in its entryway: “Our Promise: To honor God in all we do, to help people develop, to pursue excellence, and to grow profitably.”

“We emphasize team,” says Curtiss. “More importantly, we emphasize family. That’s not easy to do—to create that culture. It’s never-ending. You’re never perfect at it. But that’s what we attempt to do. That’s what we want to be. We want to truly be a family. I want everyone to walk around and feel like an owner.”

Whenever the company is profitable, it pays bonuses and donates at least 10% to charitable organizations. It also supports employee growth within the organization. “When they get here, I want them to feel a little pride in their job,” says Curtiss. “At a minimum, I want them to enjoy their work. I would like them to feel part of the team, part of the family, part of an environment that has their best interest at heart. We’re not always perfect at it, but we are on the right path. We’re on the right road to being better at it each day.”

Warren, who joined Festida Foods a year and a half ago, says the company’s culture is unique because, “every person who has a voice gets heard. All members of the management team work together to accomplish goals. A lot of times, even in small, private businesses, there are cliques and agendas. Everybody’s trying to get their own thing accomplished. I found that this company has a good culture of keeping everybody together and working toward the same goal.”

Apparently, Festida Foods’ other employees do, too. According to Curtiss, the company didn't lose any of its Cedar Springs employees when it moved to Grand Rapids.

Looking ahead

So what’s in store for the future? The company’s name may well answer that question. “I’ve told everybody here, more than once, that our company name is Festida Foods, not Festida Tortilla Chips,” says Curtiss. “While we take great pride in being what we think is one of the top tortilla chips manufacturers in the country, it certainly isn’t all we can do. The additional space that we have out there—that’s intentional. We expect to expand our offerings over the next five years.

“Where that leads us, one never knows. It will probably be in our area of expertise. But you never can tell as we’ve had a couple of offers for things that are a little bit outside our realm lately.”

Whatever the future holds for Festida Foods, it will continue to “pursue quality—in our products, relationships, operations, sanitation and shipping,” says Curtiss. “We want to pursue quality in all aspects of our business.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!