Strength in Numbers

Don Julio Foods’ team includes (left to right) Tiffany Thompson, customer service representative; Krista Rose, sales assistant; Scott Shuman, plant manager; Greg Bingham, executive vice president; Nate Fisher, president/CEO; Wendy Brooks, office manager; and Dawn Engen, administrative assistant.

A mixer full of flour tortilla dough is emptied into the hopper of a dough divider.

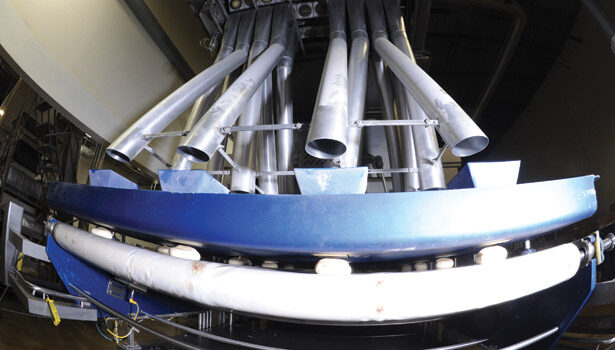

Dough balls drop from the proofer through pipes onto the press.

Dough balls are carried on a conveyor belt to the press.

Pressed tortillas go into the oven.

The company’s newest tortilla line features an automated bagger that provides hands-free packaging.

A Don Julio worker places packaged tortillas onto trays for shipment.

A Don Julio worker stacks tortillas before they head toward an automated bagger.

An LCD display system digitally scans all tortillas for size, shape and color accuracy. Tortillas that do not meet standards are automatically rejected.

A strong brand, diverse product lines, new equipment and a president and CEO who’s enthusiastic about his company and the tortilla industry have enabled family-owned, Utah-based Don Julio Foods to thrive during the present economic downturn.

The past four years have been challenging for most businesses, as the economy recovers more slowly than anticipated and consumer confidence fluctuates almost daily. Don Julio Foods, however, has tripled in size in that time, says executive vice president Greg Bingham, and “continues to enjoy strong growth.”

Founded in 1993 by Craig Fisher and run today by his son, Nate, the Clearfield, Utah-based company manufactures corn tortillas and flour tortillas under the Don Julio and Julia’s brands;

tortilla chips (white restaurant, white rounds and yellow rounds) and an uncooked flour tortilla in a resealable bag under the Don Julio brand; and potato chips under the Clover Club brand. The company also markets dips, salsas and other snacks under the Don Julio brand. All in all, the company has approximately 50 stock-keeping units (SKUs).

Don Julio Foods manufactures its products at three state-of-the art facilities in Utah: tortillas in Clearfield, Clover Club chips in Phoenix and dips, salsas and other snacks Phoenix. The three locations employ hundreds of workers.

“We’ve been very, very successful in our business,” Bingham says. “We’re showing strong increases in our brand, which enjoys the broadest recognition that it ever has in the history of our company.”

This growth resulted in a 2.5% sales increase for the company in 2011. The core customer is the traditional grocery retailer. “That’s the majority of our business,” he notes. “And we also do business with Costco and Sam’s Club. The foodservice [restaurant] side is the third piece of our business which continues to show strong growth as well. Our brand is so strong in our area, that there’s not a retailer in our core market that doesn’t know it.”

Bingham attributes the company success, in part, to Nate Fisher. “One of the things that makes us so successful is our family ownership and the enthusiasm and excitement of Nate,” he says “He has a passion for the business. He is a past president of Tortilla Industry Association and is still a board member. He’s also been a key element nationwide in the overall tortilla business.”

And Fisher is also Don Julio’s “number-one sales guy,” says Bingham. “That’s really one of the factors driving us.”

Another factor contributing to the company’s growth is its distribution model. “It’s a little different for a lot of our products,” Bingham says, explaining that the company’s tortillas are shipped fresh to retailers in neighboring Intermountain states (Arizona, Colorado, Idaho, Montana, Nevada, New Mexico and Wyoming) and in the western U.S. “We ship a lot of product everywhere, but our larger customers have their own fleets of trucks and prefer to pick up [product] because it saves them money when their semis haul stuff out and are on their way back empty.”

Customers in the greater Utah area, on the other hand, show up daily with their trucks to pick up fresh tortillas at the company’s Clearfield location. “Our snack food items are all warehouse-delivered,” he says. “That pulls costs [for vehicles, fuel, insurance, drivers and more] out of the system and allows for a little more aggressive pricing.”

Twice as nice

Don Julio Foods also offers a value line of tortillas that is very aggressively priced, as well as a higher priced, premium line. “They’re both good quality,” says Bingham, “but the one that’s priced lower is the one that’s showing the strongest sales increases right now. People are looking for a value out there.”

While both lines bear the Don Julio name, their distribution models differ slightly—some go through the warehouse and some are direct-store delivery—as does their packaging. “One is definitely a premium package, while the other one is more of a value-looking package,” says Bingham, adding that the company tries to update its packaging every two and a half to three years.

The lines’ target markets differ as well. Not surprisingly, young families looking for value and a good price are the primary purchasers of the value line.

Overall, Bingham says, that “in the tortilla world, basically the 8-in. tortillas are the number-one sellers for us. In the tortilla chip world, it’s the restaurant-style tortilla chip. In the potato chip world, it’s the ripple-style chips.”

Even though its brand is familiar to retailers and consumers in its core market, Don Julio Foods constantly promotes its products in regional grocery chains. “There are so many options out there for customers,” says Bingham. “You have to give them reasons to buy your stuff, whether it’s with in-store demos or promotions, both of which we do. You have to give the customer a reason to pick up your product.”

Gearing up for more growth

While growth is always a good thing, it often brings challenges, such as having to invest in new equipment and hire additional people. When Snack Food & Wholesale Bakery spoke with Don Julio Foods in spring 2008, the company had just taken delivery of a $3-million, state-of-the-art press.

“We were running 24 hours a day on two of our [flour tortilla] lines and couldn’t keep up with demand,” Bingham explains. “This [new] line helped us. We hope to purchase another press shortly.”

The high-speed unit, which has a 52-in. plate press and can make up to 4,500 dozen flour tortillas per hour, currently runs on one of Don Julio’s three flour lines. The company also has a corn tortilla line.

“It requires about five people to operate—fewer than the other lines,” says Bingham of the newest line. “It has an automatic bagger, which is something that’s new for us. Nobody touches the tortillas to put them in the bag—it’s all done by machine. The tortillas are counted by machine and stacked by machine. We still have an operator to handle the electronics, but it’s highly technical and computer-driven, with computer sensors that determine the sizing, color, dimensions and other parameters of the product. If they’re not up to our specs, it automatically rejects them. That’s the beauty of this press.”

The production process is equally straightforward. “All the raw materials come, in a logical sequence, into the area where all the mixing takes place,” explains Bingham. “Then, the dough goes into the dough divider, then into the press, then into the oven, then onto the cooling conveyor, then out the other end into the counter stacker, then into the bagger, then into the boxes, then onto the racks it gets shipped on and then out the other end.”

While the latest technology enables Don Julio Foods to keep up with demand for its products, it also helps the company meet safety and sanitation regulations. “All of our equipment is designed around being safe, whether it’s up-to-date sifters, metal-detection equipment or anything else to make sure the food chain is kept safe,” Bingham says.

“We take quality control very, very seriously,” he continues. “We have an internal food safety plan that that meets the standards of the American Institute of Baking (AIB), and we are inspected annually.”

Like other food manufacturers, Don Julio also undergoes regular inspections by the state health department and local authorities. “The person who runs our plant, Scott Shuman, is just the best plant manager we could ever have, and is up on all the latest inspections and standards,” says Bingham. “The only thing we do now is constantly improve and upgrade our equipment, as new innovations come out, like metal detection, for instance. We always want to get the latest and best, so we have upgraded our metal detection a couple of times over the last few years, just to make sure that we’re matching up with any new problems that might exist out there.”

As Americans continue their love affair with Mexican food and find new uses for the versatile tortilla, Don Julio Foods is ready to meet their needs and, perhaps, foster new ones. “There are quite a few things in the works right now,” says Bingham. “I can’t talk about them other than to say they will continue to expand the Don Julio brand.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!