iba 2023: ABI will exhibit alongside sister company Mecatherm

ABI and Mecatherm are both subsidiaries of the TMG holding company.

ABI’s new Katana robot scoring solution enables precise cut for a wide range of products. Courtesy of: ABI

Mecatherm's new M-RT moulder enables the shaping of hydrated dough, guaranteeing high-quality crusty breads thanks to a moulding movement close to the traditional process. Courtesy of: Mecatherm

ABI, a supplier of bakery solutions including bagel production equipment, robotics and automation solutions, announced it will exhibit at iba from October 22–26 in Munich, Germany (Hall B2, Booth 150), along with its sister company, Mecatherm.

Now more than ever, food manufacturers are facing multiple challenges. They must adapt to market demands for varied products of consistent quality while maintaining a high level of industrial performance amid a backdrop of energy challenges, labor shortages, lack of visibility on inflation and an increasing focus on environmental and social responsibility.

To help their customers face these challenges, ABI will present its latest innovative solutions at iba. In an effort to help customers meet market expectations for product diversity, ABI will be presenting its Katana robot scoring, which will deliver more flexibility than ever with its new powerful waterjet scoring system.

Expanding on features including its ultrasonic plunge and drag blade options, the enhanced Katana robot scoring solution enables the scoring of a wide range of soft products and crusty breads, guaranteeing product quality and homogeneity. In addition, the Katana robot scoring solution is particularly precise and reliable with integrated software developed by ABI, based on its deep industrial bakery sector knowledge.

Eye-Q new High Speed Vision system

ABI’s AI-enabled High Speed Vision system enables to drive improved quality control throughout the production line thanks to precise data classification. By quickly identifying the source of defects, operators can resolve production issues more efficiently and effectively, strategically positioned at a number of points on the production line (ex. after make-up and baking or at the packaging stage), Eye-Q is adaptable for a wide range of products and classifies each product in several categories based on each customer’s quality criteria and failure modes.

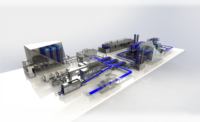

Mecatherm, a global manufacturer of equipment and automatic production lines for industrial bakery, pastry, and patisserie production, will exhibit at iba this year. (Hall B2, Stand 150).

Now more than ever, food manufacturers are facing multiple challenges. They must adapt to market demands to offer varied products of consistent quality while maintaining strong industrial performance amid a backdrop of energy challenges, labor shortages, and an overall lack of visibility on inflation, and environmental and social responsibility. To help industrial bakers face these challenges, Mecathermwill present its latest innovations at IBA.

The company will unveil its new M-VT vertical oven, suitable for baking a wide range of products, combining ease of operation and energy efficiency.

Specially designed for baking a wide range of products, from crusty bread to patisserie, pastries, and other soft breads, the new M-VT vertical oven guarantees a high level of industrial performance and product quality, while reducing energy consumption. The M-VT oven's connectivity, will also enable data collection and processing, providing a performance report and/or monitoring energy consumption while making it easier to use and maintain on a daily basis via integrated digital tools.

Solutions to support customers’ energy transition with new line-scale solutions.

The Mecatherm team will educate visitors on the company’s numerous solutions for production line energy efficiency, all aimed at supporting bakery, pastry and patisserie manufacturers’ energy transition and the reduction of greenhouse gas emissions.

"With the new compact M-VT oven, Mecatherm is affirming its commitment to continuing and accelerating its efforts in response to the increasingly complex global challenges of sustainable development.” said Raymond Nogael, vice president, marketing, business development and corporate social responsibility (CSR) at TMG.

At the production line level, Mecatherm will also present a number of innovations to help their customers reduce their energy consumption, including: an energy recovery solution installed at the oven-level to reuse energy on the production line, a new system of automated management for the oven hygrometry, and a "smart cooling system" to reduce energy consumption during the cooling stage.

“For Mecatherm, setting an example in energy transition is an important way to help our customers consume less and better, over the entire lifecycle of equipment. Greenhouse gas emissions in our carbon footprint are mainly recorded during line use (98%), with the baking phase being the most energy-consuming. It’s important to take a global approach with all the players in the industry if we are to progress successfully—all while driving enhanced understanding and innovative thinking on the scale of a complete line," added Nogael.

A new molder, designed for high-quality crusty products.

Mecatherm will launch its new M-RT molder, enabling the molding of more or less hydrated and pointed doughs using a wide range of formats and weights. This new molder guarantees the production of high-quality crusty breads, thanks to a molding operation close to the artisanal method. This equipment also meets customers' industrial performance and sustainable development requirements by guaranteeing product regularity and homogeneity and thus reducing product losses. It also contributes to improve operator ergonomics.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!