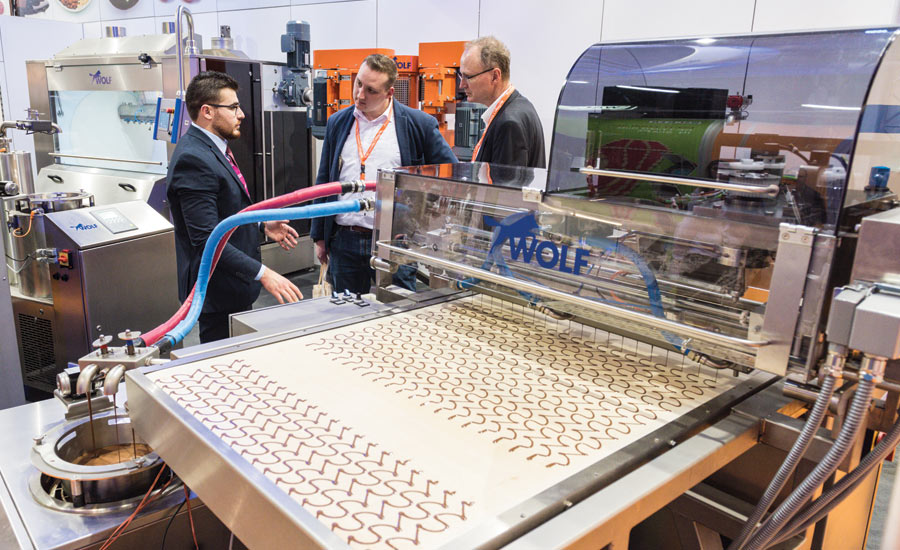

This year’s ProSweets event will connect the future of machines.

The show, which runs Jan. 27 to Jan. 30, intends to make “Industry 4.0” tangible.

Flexible machines, which make it easier to individualize products, are increasingly becoming more popular in the sweets and snacks industry. And even if many exhibitors at the Cologne fairgrounds don’t want to talk about the idea of a batch of one yet, the batches are getting smaller.

Some sweets manufacturers are even thinking about complete automation.

Automataion helps with raw material handling while also illustrating the merging of mechanics, electronics and software — from the low-dust product feeding from sacks and big bags, to the conveying and weighing of the ingredients, through to the loading of kneading units and conches.

And while manual processes quickly reach their limits, the fast recipe changeovers of automated feeding systems are making small batch quantities viable.

Industry 4.0 technologies, which permanently improve the machines in terms of self-diagnosis and error elimination, create the conditions for the efficiency many candy factories demand now. And, the packing machines for small-volume orders of sweets are designed down to the last detail.

Meanwhile, the latest generation of digital fold wrapping machines or top loading and display carton machines is completely servo-driven and is based on a highly modular concept that is consistently applied. That means high-end production lines can switch between different formats and wrapping types quickly and easily — a characteristic that specifically helps candy makers with line-ups that include seasonal goods such as Easter chocolates or chocolate balls for Christmas.

Servo-electrically driven axes are also being implemented more frequently in hollow body systems. The high flexibility for the parameterization makes it possible to produce complicated geometries with a uniform shell thickness — such as a rabbit with slightly angled ears.

It’s an example that shows that Industry 4.0 is not just for packaging. Sweets machines are increasingly becoming digitally connected and equipped with sensors that provide an abundance of data. That includes support for maintenance and cleaning processes or active notifications about the service and maintenance intervals through the machine itself.

Visitors to ProSweets will be able to see these things demonstrated at various booths, and also virtually on the screens with AR goggles.

ProSweets Cologne runs parallel to ISM, the world’s largest trade fair for sweets and snacks. With about 1,700 international exhibitors from about 70 countries, the trade fair offers a unique overview of the new confectionery and snack products worldwide and provides access to nearly 38,000 trade visitors from about 150 countries. Be sure to check out Candy Industry Magazine’s ISM new product preview in this issue.

Together with ISM, ProSweets Cologne covers the entire value chain of the production and sales of sweets and snacks at the same time and place — a worldwide unique constellation.

For more information: Visit www.prosweets-cologne.com

Chocotech

Booth: Hall 10.1 Booth B030/C039

Chocotech GmbH is a leading manufacturer of process equipment for the confectionery industry and OTC candies, which contain active ingredients. The cooking systems are designed for: Jelly, Fondant, Caramel, Fudge, Hard Candy, Chewy Candy, Fruit Snacks, Krokant, Barline Kitchens and Aeration Systems. Chocolate processing includes equipment for chocolate shells, with and without deposited fillings and Lentil Forming.

Energy Saving

The ECOGRAV is a flexible gravimetric weighing unit with a buffer tank and an integrated continuous pressure dissolver which uses the moisture of the glucose (corn syrup) to dissolve the crystal sugar (or sugar-free ingredient i.e. Isomalt) without having to add any or little water. The result is substantial energy savings. ECOGRAV is ideal for hard candies, chewy candies, fondants, cooked sugar solutions for bars and allows a dry solids level of up 90% to be achieved prior to cooking.

Lab Equipment

The PRINCESS SUCROMASTER, is a hygienically designed cooking and vacuum system for sugar or sugar-free hard candy. The standard system is designed with a static cooker type SUCROTWIST.

GEA

Booth: Hall 10.1 / G-061

GEA product highlights include the recently launched GEA SmartPacker CX250-S, a vertical form-fill-seal packaging system (VFFS) for high-speed packing of confectionery, snacks and nuts and the GEA Aquarius TwistWrapper for lollipops with its unique OverlapSeal option. This easy-to-open option provides unique added value to lollipop packaging.

GEA SmartPacker CX250-S

The new vertical bagger from GEA builds on the success of its predecessors and integrates new technologies.

The jaws of the GEA SmartPacker operate with an impressively high seal force – almost twice as high as the previous model – to enable gas-tight bags across a greater range of film materials.

The new CX250-S produces pillow bags between 70–250 mm wide and up to 0,3 kg in weight and can run up to 250 bags per minute depending on specifications.

GEA Aquarius TwistWrapper

Created with the needs of wholesalers and retailers in mind, the OverlapSeal option was developed especially for the TwistWrapper.

The standard TwistWrapper 600 with OverlapSeal handles lollipop diameters from 18 to 30 mm and accommodates film reels up to 420 mm in diameter. The minimum wrapping speed is based on 600 lollipops per minute.

Gerhard Schubert GmbH

Booth: Hall 10.1, Booth F030/G031

The lightline Flowpacker with new heat sealing technology will be at the forefront of Schubert’s trade fair presentation.

At ProSweets 2019 in Cologne, Schubert is presenting a lightline Flowpacker equipped with its latest heat sealing technology, with which heat-sensitive products such as chocolate can be packaged gently while still maintaining the highest level of performance. The Flowpacker is part of the new lightline machine series with which Schubert is offering its customers three attractively priced, preconfigured machines to take on standard packaging tasks. Additionally, Schubert Packaging Systems will be presenting its comprehensive portfolio of engineering solutions and services.

Whether chocolate pralines, chocolate bars or wafers — consumers purchase many of these confectionery products in flow-wrap bags. With the lightline Flowpacker, Schubert is offering a preconfigured packaging machine – consisting of the Flowmodul flow-wrapping component and a picker line – which packages unpacked or trayed products into flowpacks in an efficient and product-friendly manner.

Hebenstreit

Booth: Hall 10.1 Booth: D-008

Germany’s leading manufacturer of wafer production plants for flat and hollow wafers have been manufacturing equipment since 1898. Originally based in Radebul Dresden, the company relocated to Frankfurt in 1950 but continues manufacturing at both sites.

Hebenstreit is a global manufacturer of wafer production lines for flat and hollow wafers, as well as state of the art snack extrusion lines. All their equipment is designed and manufactured in Germany. They also provide a range of fully automated sugar wafer batter preparation systems, which include the feeding and conveying of raw materials.

Hebenstreit supplies single screw snack extrusion lines for various product shapes. Here the supply program also includes the process equipment for mixing and feeding of the ingredients. The snack extruder series SE is the only one combining the Turbo technology with the direct drive system which provides substantial advantages to the user. The trends in the snack extrusion are nowadays products with healthier ingredients. The raw material can vary from corn to rice, peas, soya and many others.

During the forthcoming Pro Sweets in Germany Hebenstreit is presenting their wafer baking technology where the wafer sheet size can be up to 1000 x 350mm. In addition they are also presenting their state of the art snack extruder SE 70 which also includes the well known “Turbo” and direct drive technology.

Loesch

Booth: Hall 10.1 Booth G030 H039

System manufacturer Loesch Verpackungstechnik is exhibiting together with its sister company Hastamat Verpackungstechnik at ProSweets.

The specialist for confectionery packaging is presenting its RCB-HS wrapping head machine used to produce hermetically sealed bars of chocolate. In addition to small chocolate items, the latest version of the LTM-DUO die-fold machine also reflects the growing popularity of tightly sealed chocolate bars.

Hygienic product protection and a premium look for high-quality chocolate are just as important as efficient and flexible production and packaging. Having the right equipment is therefore a top priority for any chocolate producer.

Consumers can enjoy products with longer shelf lives and an optimized taste and texture experience.

The RCB-HS operates continuously and produces the fold wrap in one wrapping head. It circumferentially heat-seals or cold-seals the packaging material as required. The sealing jaws always seal film against film, ensuring extremely tight packaging and preventing thermal damage to the products.

For an optimum look, sealing jaws carefully affix the sealed film areas to the underside of the packaging in the discharge area.

Sollich KG

Booth: Hall 10.1 Stand: B030 - C039

Sollich KG, one of the leading manufacturers of special machinery for the confectionery industry, will present numerous innovations at the ProSweets 2019 in Cologne.

On display at the Sollich booth will be the Turbotempere type TE 1100 D with a tempering capacity of 1100 kg per hour. The patented tempering process provides optimum tempering of different types of chocolate, resulting in a constant enrobing quality, a high shelf-life and an attractive gloss of enrobed or moulded products. The integrated touch panel with intuitive surface and recipe management guarantees easy handling and reproduction of the machine settings.

Besides the well-known Enromat enrobing machines with working widths of up to 2,600 mm also the Temperstatic series with belt width of between 820 and 1,300 mm including integrated tempering belongs to the Sollich manufacturing range of enrobing machines. The enrober type Enromat M6-1050 CIP on display, with a belt width of 1,050 mm, allows numerous possibilities to adjust a precise adjustment of the product coating.

Furthermore, Sollich will show the new compact mini enrobing machine type Minicoater MC 420. The machine will be run with chocolate mass during the exhibition period. It is available in 320 and 420 mm working width.

Tecno 3

Booth: Hall 10.1, Booth D078 - E079

TECNO3 is pleased to announce its participation at the Prosweets exhibition in Cologne, Hall 10.1, Booth D078 - E079 where our technicians will show you the following machines:

BEAN-TO-BAR LINE:

The line is made up of two compact units specially conceived for small chocolate production capacities:

a) Multiprocess R: from the bean to the nibs (roasting, debacterizing, winnowing). The line offers excellent results in nut roasting and debacterizing. All parts are easily and rapidly disassemblable for sanitization.

b) Multiprocess C: from the cocoa nibs to the chocolate ready to be moulded (mixing of ingredients, refining and conching). Sanitizing and recipe changeover are enabled thanks to the absence of pumps and pipes and the easy disassembly of all the machine parts. The system can also produce pastes from nut and lipid base cream.

LIPID BASE CREAM LINE:

The line consists in one vertical mixer where all the ingredients are loaded, a conveyor belt to feed the mixture and a refining unit mod. P10S400 (a combination of two- roll, -vertical roll and ball- mill refiners).

ORM: robotized station for automation and flexibility of the production processes.

Winkler und Dünnebier Süßwarenmaschinen

Booth: Hall 10.1, Booth B050

Winkler und Dünnebier Süßwarenmaschinen GmbH (WDS) is one of the leading international manufacturers of confectionery machines and well known for permanent development and innovation of its production plants. With its extensive machinery program they are able to cover the entire spectrum of deposited sweets with different applications and throughputs and stand worldwide for highest quality and reliability.

WDS presents ConfecPro Type 670 production line at ProSweets

A main topic at ProSweets 2019 will be the presentation of the ConfecPro Type 670 chocolate production line. The concept of the plant is addressed to confectionery manufacturers who want to target a medium to high output quantity – together with a scheduled growth-oriented expansion of the plant right from the beginning.

This is exactly what the ConfecPro Type 670 offers, as its design is modular and, together with decentralized electrical control of the plant components, ensures both small expenditure during the initial assembly as well as during later expansion.