Photo Galleries

New Processing Equipment: January 2023

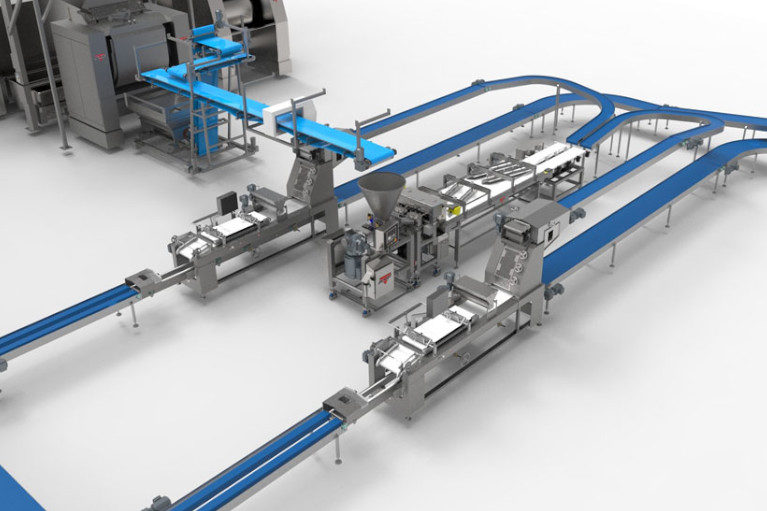

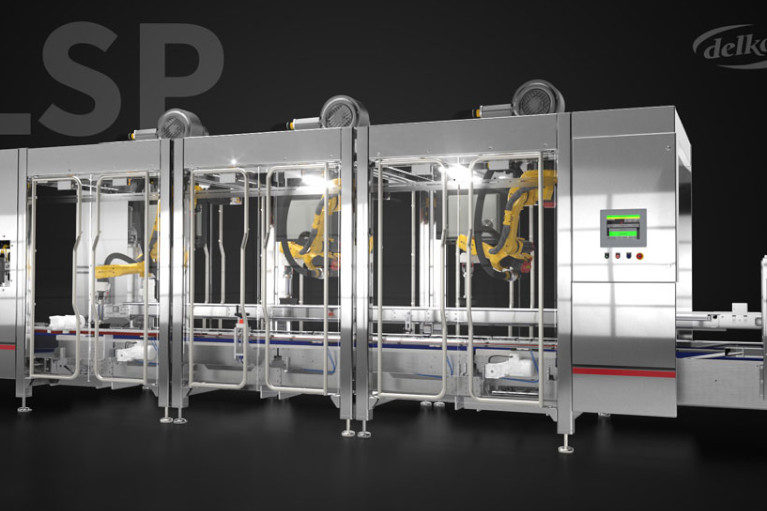

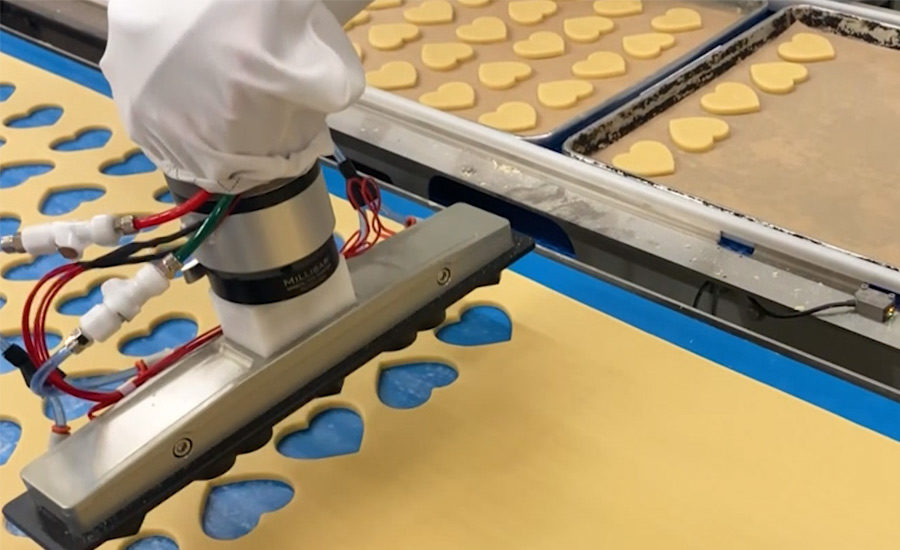

Robotics and automation are changing the snack and bakery production landscape by providing a more consistent product, improving workplace safety, and freeing up employees for other tasks. The technology allows bakeries to run production lines at faster speeds and with more accuracy than ever before while taking up less space.

New Packaging Equipment: December 2022

The evolution of palletizing is linked to robotics. In fact, robotic palletizing of flexible bags in snack and bakery plants is a reliable way to handle variations in weight. Modern robotic palletizers also can be equipped with programmable HMI (human-machine interface) and end-of-arm-tooling (EOAT) that allow manufacturers to quickly switch between a variety of bag sizes, weights, and materials.

New Processing Equipment: December 2022

Snack food and wholesale bakery companies looking to purchase or upgrade their laminators and sheeters focus most on features and benefits like flexibility, sanitation, and automation, according to companies that manufacture such products.

New Processing Equipment: November 2022

Novel ingredients and formulations—including some aimed to be “better-for-you” and others intended to be “fun”—are high on the list of features and benefits snack and bakery companies would like to see in extrusion equipment, along with ease of cleaning and maintenance, efficiency, and (naturally) the ability to produce a high-quality product.

New Packaging Equipment: November 2022

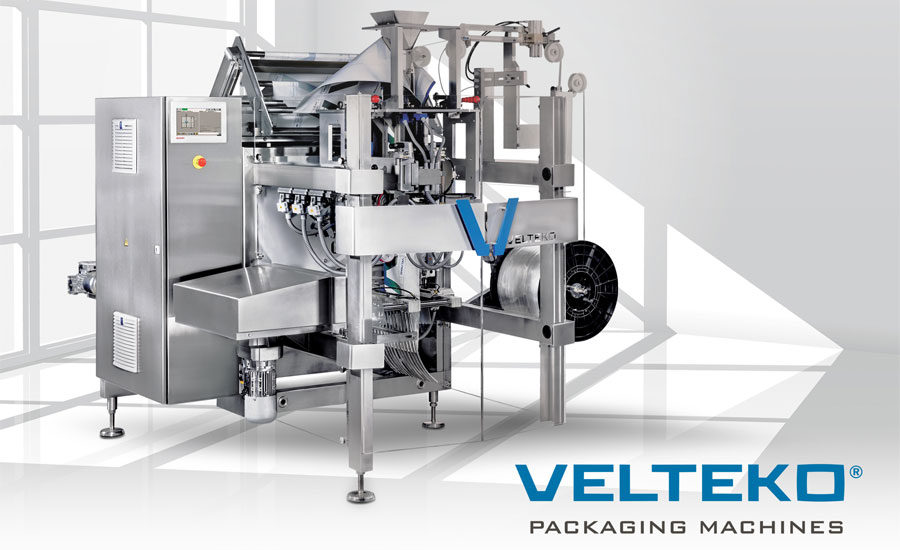

Flexible packaging equipment—vertical and horizontal form/fill/seal, flow wrapping, pouches, film, and roll stock—has evolved to the point where it can handle a wide range of packaging shapes and sizes to meet the demands of consumers and retailers.

New Processing Equipment: September 2022

Energy efficiency, automation, and ensuring a robust return-on-investment have been top-of-mind for snack food and wholesale bakery companies in the market for ovens and proofers, according to companies that make those machines, who say sales have been strong.

New Packaging Equipment: September 2022

Bakery and snack plants are moving away from manual cartoning and case packing to automated equipment.

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpeg?height=600&t=1668018175&width=900)

.jpg?height=600&t=1665689392&width=900)