Home » food safety

Articles Tagged with ''food safety''

Increasing sanitation, dividing production teams among measures taken to enhance safety, maintain production.

Read More

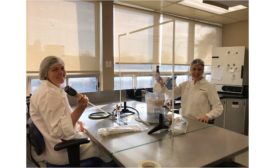

How Blommer Chocolate Co. is handling the COVID-19 pandemic

Enhanced sanitation, staggering shifts among the safety measures Blommer has taken.

June 3, 2020

Atkinson Candy’s Texas facility achieves SQF certification

Company began working on facility overhaul to better segregate allergens.

April 29, 2020

‘There’s no rulebook for this’: St. Louis chocolate company VP talks weathering the coronavirus crisis

Chocolate Chocolate Chocolate Co. has ramped up manufacturing safety protocols and closed retail stores while experiencing a drop in sales.

March 27, 2020

When are fewer food recalls a bad thing?

A new Stericycle Expert Solutions report says the recent government shutdown meant fewer recalls. Here’s why that’s cause for concern.

May 8, 2019

Top trends in snack and bakery packaging safety

New technologies keep goods fresh and extend shelf life

April 15, 2019

EU commissioner right to say ‘fake news’ hurts food industry

Vytenis Andriukaitis says fake news can damage citizen’s trust in food system and science.

February 27, 2019

How inspection systems help candy makers get the most out of production

New product offerings, package formats present challenges that may require upgraded inspection systems.

November 28, 2018

Metropoulos family-owned firm acquires NECCO after Spangler deal falls through

Round Hill Investments purchases NECCO for $17.3 million.

June 5, 2018

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing