Reading Thermal has released its SCORPION 2 Digital Air Velocity Sensor Array. The redesigned Air Velocity Sensors use a thin-film platinum RTD construction that greatly improves sensor to sensor variation, while proprietary Smart Temperature Compensation allows its calibrated arrays to accurately measure both high and low temperature environments.

More improvements/additions include:

- Smart Temperature Compensation for accurate high temp measurements

- New thin-film platinum RTD construction for the best in sensor-sensor repeatability

- Improved response time by up to 37%

- Efficient digital power circuitry for up to 2x battery life over analog

- Dedicated 24-bit Analog to Digital converters for improved resolution

- Existing arrays can be upgraded to the new technology

- No change in user procedure to learn new sensor

- Free software upgrade

- Compatible with 32mm tall systems

For customers who already own existing Air Velocity Arrays, special pricing is offered to upgrade to Digital Air Velocity Sensors. This upgrade is compatible with all SCORPION 2 Systems.

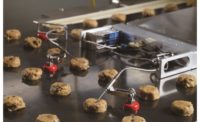

Even distribution of airflow is vital in maintaining the quality of product delivered by any oven system. In a radiant oven (e.g. ribbon burners), the airflow comes from the moving conveyor, the exhaust system, and natural combustion air currents. In a convection oven, (e.g. air recirculation), the airflow comes primarily from the air distribution plenums. In this case, airflow is of particular importance because it directly controls the amount of heat delivered to the product.