Kivnon will showcase the latest addition to its AGV portfolio, its Forklift Pallet Stacker, at this year’s ProMAT, running March 20–23 in Chicago. Kivnon AGVs/AMRs are heavy-duty vehicles designed to improve safety and process efficiency.

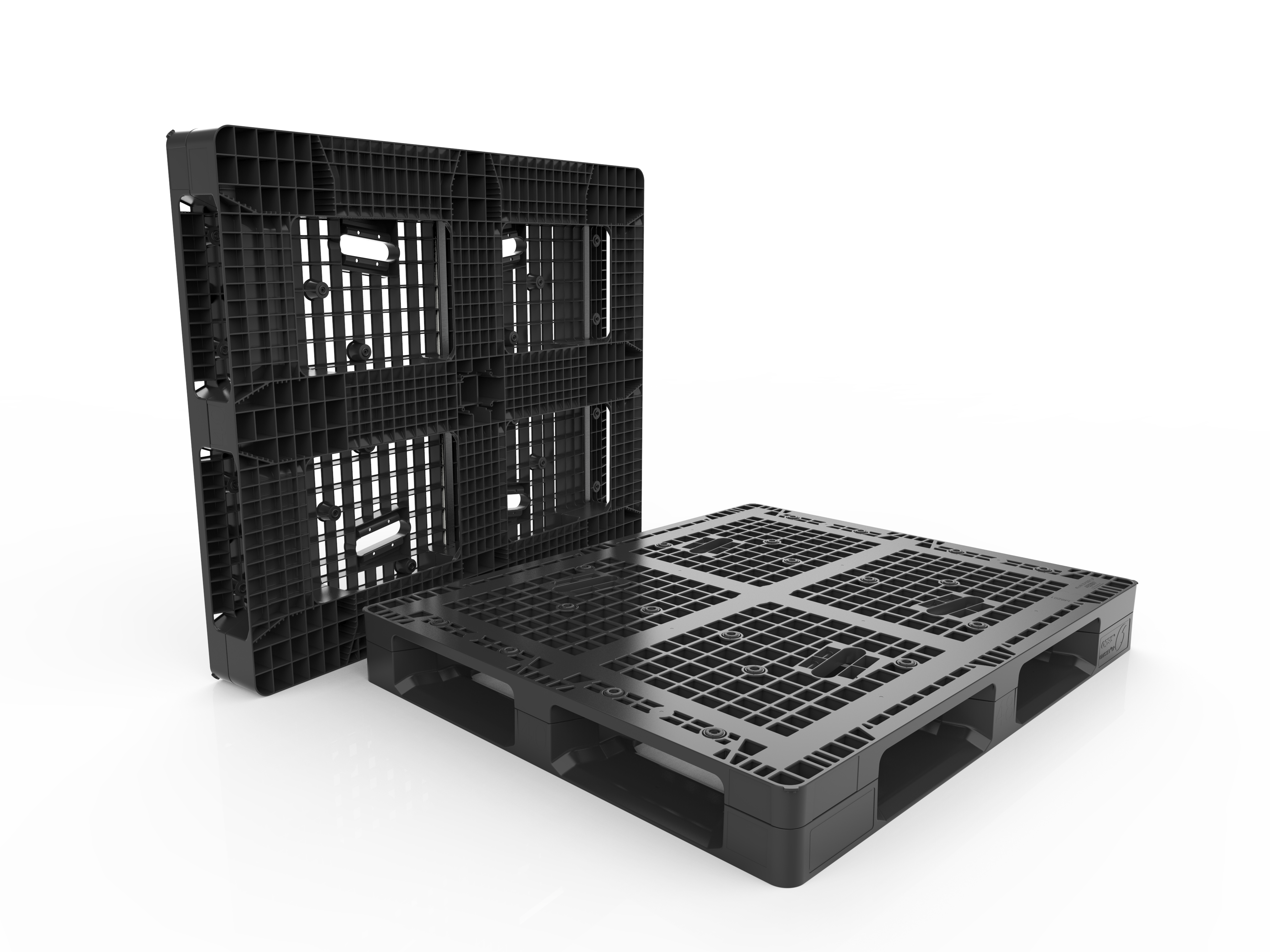

The new Forklift Pallet Stacker automatically transports stack pallets, handling loads of up to 2,645 lbs, and is suitable for any pallet storage application for internal logistics or warehousing. It can move both forwards and backward and comes equipped with lifting forks to move loads vertically (up to 1.5 meters) and horizontally at speeds between 0.08 and 1 m/s.

The vehicle uses mapping navigation to perform cyclic or conditioned routes and interacts with other AGVs/AMRs, machines, systems, and people to provide a versatile, plant-wide logistics solution. The entire Kivnon AGV/AMR range incorporates security scanners to allow the vehicle to operate safely among people and other machines. An online battery charging system ensures 24/7 operations without the need to stop and charge.

Rob Britt, sales engineer at Kivnon, says, “Safety is our top priority. The fundamental design of the Forklift Pallet Stacker is to move stack pallets efficiently and safely. It is ideal for applications including the Automotive, Manufacturing, and Food and Beverage industries. Our vehicles get the job done, and our local support experts will help customers with all stages of the project, from project definition to ensuring they get the support they need for the life of the machine.”

After installation, Kivnon offers service response is tailored to individual customer needs, whether that be training to enable sites to maintain their vehicles or complete 24/7 support from Kivnon experts. The company provides local support with direct and quick access to local, experienced automation engineers to advise and guide them toward successful vehicle automation.

Kivnon vehicles follow standardized fundamental designs that make them flexible to match the purpose of the machine at a facility and individual business goals. This approach means customers are not paying for extras they do not need.

Britt continues, “Quite simply, our customers get a better product at a better price. We cater to any size project, small or large, and provide solutions that ensure worker and vehicle safety.”

“You can expect a return on investment from one of our AGVs in less than 12 months. We invite customers to visit us at ProMAT and get a firsthand experience of the Kivnon approach to vehicle automation—an approach that means you can increase efficiency, ensure safety and reliability, and only pay for the product and support you need,” concludes Britt.

.jpg?1675179439)