PMCA Preferred Supplier Profiles

Cargill Cocoa & Chocolate

Tanis Food Tec

Royal Duyvis Wiener B.V.

Petzholdt Heidenauer

Hebenstreit

Fast Track Engineering

Sollich KG

Chocotech

AAK-USA

Caotech

Buhler AG

BCH Ltd.

Barry Callebaut

ADM

Aasted

AAK-USA

AAK-USA Inc.’s products are derived from natural and nutritious raw materials and have been developed using a high degree of technology. For example, cocoa butter alternatives provide solutions to eliminate trans fatty acids in bakery shortenings, frying oils and many other dairy and bakery applications where no trans fats, no hydrogenation and low saturates are a must.

CEBES, the company’s cocoa butter substitute (CBS), is a non-temper compound that simulates the best attributes of real chocolate. WithCEBES, confectioners can produce a cost effective compound coating with excellent functionality, a fast crystallization rate, a steep melting curve and good melt-down and flavor release without tempering.

CEBES NHis a non-hydrogenated CBS with zero trans-coating-fats, and is used to achieve higher melt points and improved functionality without trans fats or hydrogenation.

ILLEXAO, AAK’s cocoa butter equivalent (CBE), uses raw materials approved by the EU Chocolate Directive and subject only to refining and fractionating processes during production. It gives manufacturers supreme versatility and can be used without alteration to existing production processes.

CONFAOHigh End Filling Fats are high quality and have a neutral taste and aroma. They are also bloom-resistant in specific applications where chocolate may be present. In addition, the fats are non-tempering, have zero trans-fat and are non-hydrogenated.

For more information, visit www.aak.com or stop by booth 24.

Aasted

Aasted, a world-class supplier of chocolate moulding lines, tempering machines, enrobers, cooling tunnels, chocolate, bakery and confectionery depositors and extruders, bakery lines, ovens and auxiliary equipment will have a table-top exhibit at the PMCA Production Conference.

Visitors will have an opportunity to review materials detailing some of the company’s latest innovations, including the Supernova Energy 1000-P tempering machine, theAlice depositor and extruder, Nielsen enrobers and the Nielsen cooling tunnel SD.

The SuperNova Energy tempering program is a groundbreaking debut from Aasted that saves at least 50% in total energy consumption in comparison with traditional tempering machines. The energy tempering technology raises the quality of the tempered chocolate to an unprecedentedly high level and even handles high-fat content mass without a decrease in capacity.

Today, Alice depositors and extruders for bakery and confectionery products are well-recognized for their outstanding “gentle” handling of dough, caramel and inclusions. The row of accessories is extensive and comprises nozzle plates and nozzles, tailor-made for any requested product, traditional wire-cutters, highly innovative guillotine and ultrasonic cutters.

For more information, visit www.aasted.eu or stop by booth 135.

ADM

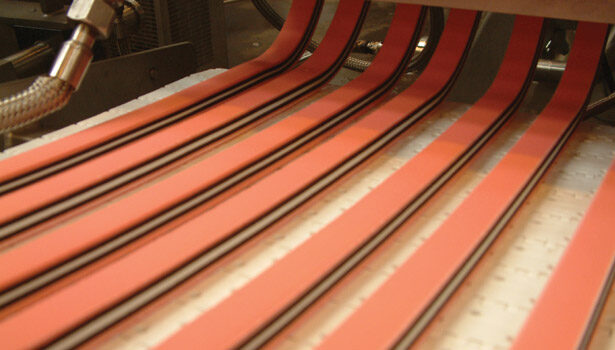

Known for its consistent and superior quality, the Merckens brand of premium chocolate and Rainbow coatings have become a top choice among discerning chocolate retail confectioners for more than 85 years.

Available in white, blue, green, orange, orchid, peach, pink, red and yellow, Merckens Rainbow color wafers and compound coatings will turn your creations into eye-catching and mouthwatering works of art. We’ve made it easy to create more than 70 additional colors by mixing our standard colors with the help of our simple Color Magic Chart. And to give your creations even more consumer appeal, our Rainbow coatings are available in multiple flavor profiles—including dark and milk chocolate.

The confectionery applications for Merckens Rainbow color wafers and compound coatings include solid moulding, panning, decorating and enrobing centers. They give you the opportunity to add extra flavors and attention-getting colors to chocolates, candies and other confections.

In addition, our experienced teams of sales, customer service and product development specialists are available to lend their expert assistance.

For more information, visit

adm.com/merckens or stop by booth 65.

Barry Callebaut

Barry Callebaut is the world’s leading manufacturer of high-quality cocoa and chocolate products. Our product portfolio includes cocoa powder, chocolate and compound ingredients for confection, bakery and ice cream applications. Our proven expertise, together with our focus on innovation and R&D, enable us to cater to many customer needs.

Barry Callebaut will be showcasing examples and tastings of our product portfolio breadth from coatings to inclusions to cocoa powders that will solve your daily product development challenges. You will see that Barry Callebaut is your chocolate solution provider with innovation at the core of our focus!

For more information, visit www.barry-callebaut.com or stop by booth 9.

BCH Ltd.

BCH’s latest innovation is a confectionery extrusion line that can produce two different confectionery products using the same line and equipment, be it licorice and marshmallow, licorice and 100% fruit or high-percentage fruit and nut snack bars.

As Matthew Cottam, BCH’s technical director points out, “I feel that in today’s economic market we need to give our worldwide customer base adaptability, reduced financial outlay and added confidence in their investments and product range. This multi-use line gives our customers exactly that.”

BCH’s micro-confectionery extrusion line provides a cost-effective solution for new start-up companies as well as certain developing markets within the Middle East, Africa and Asia who wish to gain a foothold in the sector, without committing huge initial outlay.

The new line has a 300mm product width for output capacities of up to 150 kg/hr fruit gummy extrusion and 300 kg/hr co-extrusion. It also offers the capability for 100% fruit and vegetable extrusion to suit the latest consumer trends for natural, organic and clean ingredient labels on snack products as well as traditional confectionery products.

For more information, visit www.bchltd.com.

Buhler AG

Looking in to the future of chocolate production, one could easily argue that the industry will look completely different in ten years. Since this prediction is not very difficult, the more important question is what aspects will cause the changes?

Words such as efficiency, hygienic design and flexibility are becoming more essential in the chocolate manufacturing industry. The equipment should be efficient in energy consumption, have a hygienic design to avoid any problems with the end product, and have a flexible approach.

Buhler, as an innovative supplier in the chocolate manufacturing industry, has faced these trends and developed new solutions for both emerging and established markets.

For more information, visit www.buhlergroup.com or stop by booth 28.

Caotech

Caotech b.v., based in Wormerveer - the Netherlands, has a worldwide reputation as specialist in self-developed ball mills and conches within the cocoa and chocolate-related processing sector.

The photo illustrates our best selling line at the moment for Caotech, the CAO 3000 CHOC (In-Line) installation as it appeared at the recent ProSweets Exhibition, a fully automated processing line for the production of chocolate and compound with capacities of up to 1,500 kg per hour. It is our ‘top line,’ and provides a good return on investment. Customers can produce against very low operational costs, thus earning a quick payback.

At this moment, we are supplying most of our equipment to companies in emerging countries where customers appreciate the level of automation and efficiency we can supply them. Thus, it’s no surprise that they’ve become very familiar about how to get to Holland.

In addition, the continuing growth of niche markets, such as organic and fair trade, fits perfectly with our ability to supply the right equipment.

For more information, visit www.caotech.com.

Cargill Cocoa & Chocolate

Whether you are a veteran candy maker or starting in the business, Cargill Cocoa & Chocolate has four unique brands to meet your needs. Wilbur features a line of chocolates that offer rich, bold American flavor profiles. Peter’s remains faithful to its Swiss heritage, combining its proprietary milk crumb base with chocolate liquor to create superlative chocolate.Veliche is 100% Belgian chocolate in wafers while Gerkens Cocoa is a full line of natural and Dutched powders.

For more information, visit www.cargill.com or stop by booth 46.

Carle & Montanari OPM

Carle & Montanari and OPM combined their know-how to create the first Italian group capable of providing complete, turnkey solutions for the processing and packaging of chocolate and confectionery products.

This joint venture between Carle & Montanari and OPM means customers will be able to count on a sole supplier to propose flexible, personalized solutions for every possible production requirement.

Our complete lines follow the product starting from cocoa processing and chocolate mass preparation with our wide range of cocoa presses, mixers, pre-refiners, refiners and conches. Moreover, we can boast of having the most experienced and most innovative and efficient solutions.

Our moulding lines represent the state-of-the-art in the chocolate world; they include both intermittent and continuous motion moulding plants, depending on the customer’s needs.

In the field of packaging we offer customers a wide choice of packaging solutions, from aligners and feeders to wrappers and carton erectors.

Visit www.carle-montanari.com or stop by booth 17.

Chocotech

Chocotech, which is represented by Sollich North America, offers complete cooking systems for jelly, fondant, caramel, fudge, hard candy, chewy candy, fruit snacks and krokants as well as barline kitchens and aeration systems.

On the chocolate processing side, Chocotech also offers the Frozenshell line with Pralimat depositing, lentil forming and enrobing.

With the new Ecograv, Chocotech can now achieve batches of much dryer solids prior to cooking. This can result in large energy savings compared to other systems.

The Sucrofilm/Sucromaster provides for continuous manufacturing of hard and soft candies.

Visitors at Chocotech’s tabletop booth can also get more information about the efficient production of jelly products using the Jellymaster.

The Jellymix, which is a gravimetric weighing and feeding system to deal with up to eight different colors and flavors, can also handle aerated foam.

For more information, visit www.sollichna.com or www.chocotech.de and stop by booth 47

Fast Track Engineering

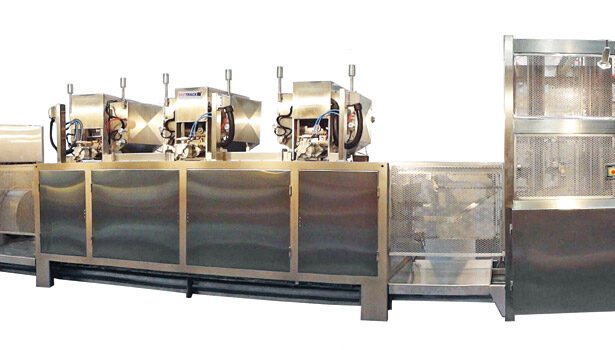

FastTrack Engineering has three types of moguls available.

The FAM type mogul is the most flexible machine available on the market, with a tray speed of up to 32 trays per minute in production, using half tray pumps, which will allow the operator to change from one product to the next in the least amount of time.

The SCM type mogul is the fastest machine available on the market, with a tray speed of up to 36 trays per minute in production.

The FAM-OD type mogul is a special machine designed and manufactured to operate in conjunction with a chocolate enrobing line. The product is discharged from the de-moulding section in an orderly formation. The unit operates at a top speed of up to 22 trays per minute.

FastTrack Engineering can provide all the equipment necessary to operate with a mogul line designed and manufactured for the 21st century — ranging from a starch conditioning system and a pallet transportation system that includes fully computer-controlled drying rooms to product finishing equipment such as sugar sanding line and oiling equipment.

For more information, visit www.ftengineering.com.au.

Hebenstreit

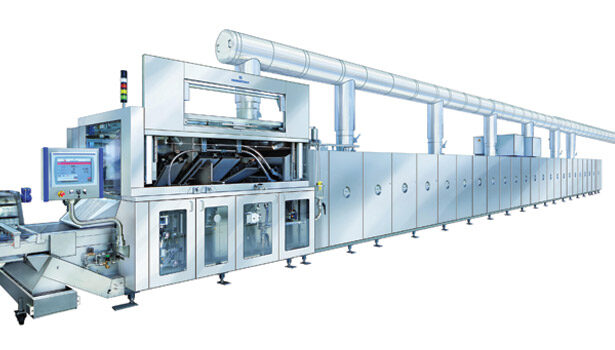

Hebenstreit is recognized worldwide as the manufacturer for state-of-the-art wafer production lines for flat and hollow wafers. The company’s wafer production lines range from medium- to high-capacity and are all designed and manufactured in Germany.

The turnkey systems encompass the following: equipment for raw material feeding technology; batter and cream mixing systems; baking machines; sheet coolers; conditioning systems; cream spreading and layering machines; cooling units; cutting machines; and the necessary downstream equipment for feeding the wafer fingers directly to the wrapping machines or any post-connected equipment such as chocolate enrobers, moulding lines etc.

Product development, formulation improvements and technical support as well as training courses are another very important part of Hebenstreit’s customer service.

As a medium-sized company, Hebenstreit can still provide its customers with a special personal touch. The company is constantly improving its technology, and, as a result, the output of their wafer machines has recently risen significantly.

A “green burner” technology is applied to bake the wafers with a minimum of energy consumption. As a result, it’s not that many of the world’s most popular wafer products are made with Hebenstreit’s technology and support. To experience “excellent engineering for delicious results,” Hebenstreit’s the choice.

For more information, visit www.hebenstreit.com.

Petzholdt Heidenauer

Over the last several, Petzholdt Heidenauer has focused on optimizing and developing its chocolate processing machines. One example of that effort, the company launched a new, more efficient five-roll refiner.

In redesigning its machines, Petzholdt Heidenauer combined the benefits of classic cocoa processing with the latest optimizations available in automation and technology.

Thus, the new Roaster conserves energy consumption and comes with a new air system and more safety features. The new winnower has an automatic opening for better access for maintenance. And the newly designed crusher features an automatic air adjustment, which helps to reduce the percentage of fine parts.

In addition, the company’s range of mills has been expanded to include a new beater blade mill as well as a ball mill, both with capacities up to two tons per hour.

The HBM V Vacuum Mixers for the treatment of cocoa liquor represent a totally new development within the cocoa processing machines range. These mixers are available for batch sizes from 500 to 5,000 kg. and are used for sterilizing, alkalizing and treating cocoa liquor with live steam.

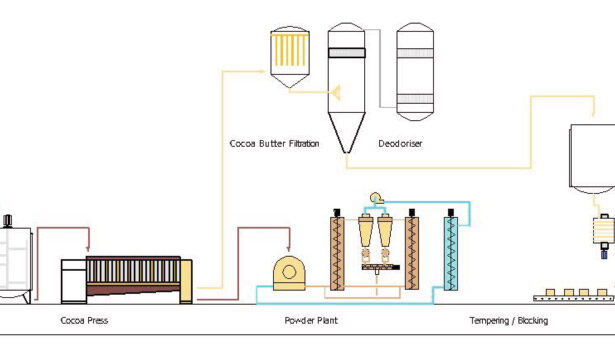

The company also offers complete turnkey cocoa factories.

Thus, the company proudly says that “we are back in cocoa processing.”

For more information, visit www.petzholdt-heidenauer.de

Royal Duyvis Wiener B.V.

Royal Duyvis Wiener announced it will partner with one of Peru’s largest cocoa farmer cooperatives, Cooperativa Naranillo de Cacao y Café (Coopain). By investing $3.3 million, Coopain looks to increase production capacity by 400%.

Coopain’s recent investment focuses on the second phase of technological improvements at its Tingo Maria cocoa plant. As a result, cocoa bean production capacity will increase from 3,000 to 15,000 tons per year. In addition, bean quality and value will also improve.

Rolando Herrera Ramírez, president of Coopain, declared that the second phase of the technological plan consists of implementing modern machinery being imported from Germany. Royal Duyvis Wiener will participate in this project with a complete Lehmann cocoa cleaning, roasting, winnowing system and a Wiener cocoa liquor grinding line.

Coopain estimates the project will generate a 400% productivity gain. The investment will be executed within approximately 14 months.

For more information, visit www.duyviswiener.com

Savage Bros. Co.

For more than 150 years, the Savage Bros. Co. has continuously manufactured confectionery machinery. Our candy making and chocolate making equipment are recognized worldwide for enduring quality and reliability.

From these 19th century roots in the candy industry, Savage equipment has applications today for the bakery, food processing, cosmetic, pharmaceutical and material handling industries. Savage Bros. strives to meet its customers’ equipment needs with well-designed and manufactured machinery.

At the PMCA Production Conference, the company will be exhibiting its table top electric cooker, a gas cooling candy stove as well as a lifter dumper and chocolate tempering unit. The company will have brochures of its equipment available and will be displaying videos of different candies cooking.

For more information, visit www.savagebros.com or stop by booth 32.

Sollich KG

Sollich KG of Germany is the world’s leading supplier of enrobers, tempering systems, cooling tunnels and bar forming equipment as well as a complete range of associated equipment. One example of the company’s continuing innovations in tempering is the Flex Tempering machine, which was introduced at Interpack 2011.

The TT Flex incorporates the industry’s leading TT tempering technology, but now offers the ability to have a greater range of throughputs from 30% to nominal capacity. This “flexibility” allows for greater production and energy efficiencies.

Another proven system in the Sollich product range is the Enromat M5 CIP enrober.

One example is the patented wire tensioned detailer system, which has eliminated the clips normally required to hold the detailer rod in place. Another major feature that’s designed into this coater, is the automatic washing system design for cleaning changeovers.

Sollich North America represents Sollich KG in the United States and Canada.

For more information, visit www.sollich.com or www.sollichna.com and stop by booth 47.

Tanis Food Tec

Dutch food equipment manufacturer Tanis Food Tec specializes in processing lines for bakery fillings and confectionery products. Its latest launch, the Roto MallowPlant, is a new marshmallow production machine that combines cooling, aeration and extrusion of the product at a low temperature. The line delivers a full range, from basic ingredient cooking to ready-to-pack product.

Having a marshmallow product hold its shape after extrusion has always been a key problem, as the required higher temperatures during the aeration process makes the product rather fluid. Shape loss was inevitable.

Tanis has solved this by integrating a cooling device between the aerator and the manifold extruder.

Manufacturers benefit because they can now make and replicate their marshmallow product exactly as it was originally designed — round marshmallow will remain a 100% round instead of flowing out into an egg-shape.

Another added value of extruding at lower temperatures is that the final cooling line can be much shorter.

For more information, visit www.tanisfoodtec.com.

Union Confectionery Machinery Co.

Union Confectionery Machinery Co., a fourth-generation, family-owned business since 1912, is the world’s largest supplier of second-hand, used and rebuilt machinery for the confectionery, food, packaging, processing and biscuit industries. The firm’s world headquarters are located in New York and consist of a 270,000-sq.-ft. building that contains sales and executive offices, a full rebuilding facility, massive warehousing and shipping and receiving areas. It also operates a similar plant in Mexico.

Union’s customer base is worldwide and encompasses a wide range of clients from Fortune 100 firms to small and mid-sized, family-owned and corporate entities. It can supply modern used and rebuilt machinery solutions for manufacturers in many different fields including: chocolate production, sugar confectionery, biscuit and general packaging applications.

The company’s rebuilding facility is the largest in the world among used equipment dealers and its staff are well trained in sales support, engineering, mechanical repairs, electrical upgrades and PLC programming.

For more information, visit www.unionmachinery.com or stop by booth 69.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!