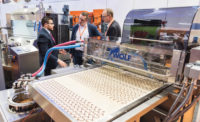

At this year’s ProSweets exhibit, the company focuses on displaying its newest line of energy saving equipment — the Nielsen Energy Enrobing Concept. It’s a concept that enables large energy savings by direct injection of the tempered chocolate mass from the tempering machine to the consumption flow, ensuring a homogeneous tempered mass as well as a constant tempering index and temperature in the enrober.

A combination of the Nielsen Energy Enrober with our SuperNova Energy tempering machine will result in a reduction of up to ⅔ energy consumption. The full energy circuit will be on display at Prosweets with a Nielsen Energy Enrober 1,300 mm width piped with a SuperNova Energy tempering machine 800 CTS.

Visitors to the booth will see the following machines on display:

Nielsen Energy Enrober 1300

The Nielsen Energy Enrober comes in widths from 420 to 2600 and is characterized by simple operation and precision control, an advanced closed water system, and documented reliability in three-shift operation. It has an easy adjustable and flexible flow pan with optimal distribution of chocolate providing a uniform chocolate curtain. With the new energy enrobing concept it makes large energy savings possible as well.

SuperNova Energy Tempering Machine, type 800 CTS

The SuperNova Energy tempering program is a groundbreaking world-release from Aasted that saves at least 50% in total energy consumption in comparison with traditional tempering machines. The SuperNova Energy tempering program covers everything from straight heat exchanging of any pumpable mass to highly precise Beta crystals in high-quality chocolate mass.

Alice 800 Triple Head

The program of Alice depositors and extruders for bakery and confectionery products is today well-recognized for its outstanding “gentle” handling of dough, caramel and inclusions. The row of accessories is extensive and comprises nozzle plates and nozzles, tailor-made for any requested product, traditional wire-cutters, highly innovative guillotine and ultrasonic cutters.

Nielsen Cooling Tunnel, Sanitary Design

The Nielsen Cooling Tunnel SD - Sanitary Design is developed and designed for use in production areas and industries with very high requirements to the equipment design in order to obtain the highest degree of hygiene. The Nielsen Cooling Tunnel SD is very energy-efficient and a safer choice for the environment. An important feature is the cooling compressor housing, which is designed for easy and fast cleaning.

Sophus 500 depositor

TheSophus Depositor program comes in widths from 500-1,200 and is our inexpensive depositing solution for standard chocolate masses for our standard modular lines, Jensen and Jensen Flex, as well as belt lines. This depositor program comes with features such as Easy Clean, fast changeover, and is expandable from single- , double- and triple-shot.

At ProSweets, visit us at Hall 10.1 booth F011 or go to www.aasted.eu