New Processing Equipment: March 2022

Companies that make seasoning and coating systems for snack and bakery applications, which mostly focus on salty snacks like chips, cheese puffs, pretzels, and popcorn, report a number of trends in requests regarding features and benefits from customers of such machines during the COVID-19 pandemic of the past couple years.

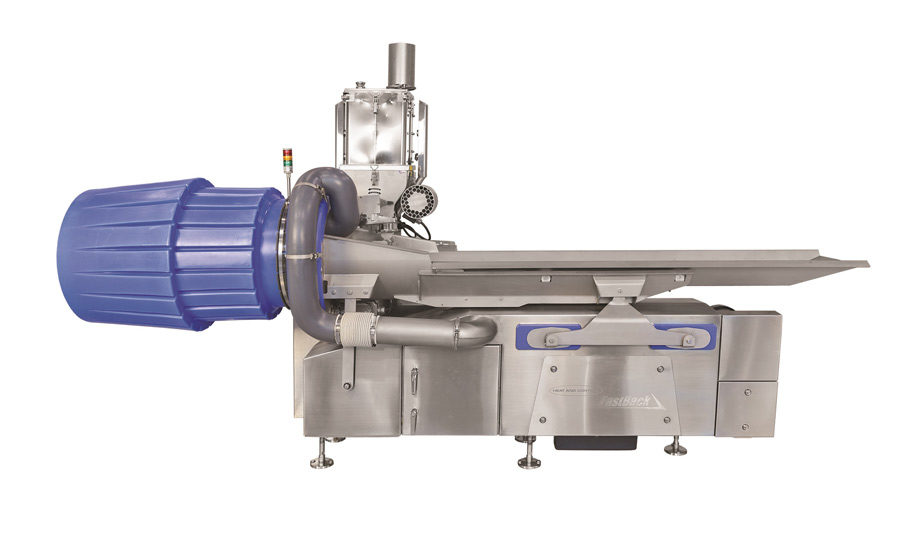

Heat and Control

Website: www.heatandcontrol.com

Equipment Snapshot: Heat and Control has released the Totally Automated Seasoning Control (TASC) complete seasoning solution, encompassing the Revolution Gate to the Ishida weigher and the AirFry System, and featuring the Spray Dynamics system that precisely meters oil usage. The closed-loop seasoning control strategy provides instantaneous feedback to improve seasoning performance, reducing labor costs by lowering the need for offline analytical quality control tests due to its accuracy, decreasing consumer complaints, and product holds.

PPM Technologies

Website: https://ppmtech.com/

Equipment Snapshot: The snacking business has boomed during the pandemic with people working from home, which has meant the need to be able to handle a greater variety, says Neil Anderson, vice president of business development for PPM Technologies, Newberg, OR. As manufacturers of snacks start to implement those additional varieties, the cheapest way is to maintain the base product and keep coming out with new flavors, he says. PPM has been working more with snack makers in Latin America, who Anderson notes tend to have “different standards for flavorings than in the U.S. We’ve had to modify the design of our equipment to accommodate that. The put on a very high percentage of spicy types of flavorings.” Their demands have increased, as well, he notes.

Tinsley Equipment Co.

Website: www.tinsleycompany.com

Equipment Snapshot: Tinsley, which offers the Electrostatic Seasoning and Food Coating System, has been working to create a more simplified package among the feeding, enrobing and application processes. Tinsley also has undertaken controller upgrades to improve the interface to the machinery.

tna solutions

Website: www.tnasolutions.com

Equipment Snapshot: tna has designed the intelli-flav OMS 5.1 to accurately monitor seasoning quantities, ensuring that the right amount of oil, salt or other coatings are applied via intelligent control and monitoring software to reduce waste and increase profitability. The on-machine seasoning system offers consistent coverage for wet and dry ingredients in a single drum. The intelli-flav system uses preprogrammed recipes to apply the precise amount of seasoning needed, while also addressing additional challenges for customers.

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing