Items Tagged with 'automation'

ARTICLES

Labor shortage fueling investment in warehouse automation: PMMI

Building automation into ovens, proofers, and ancillary equipment

Robotics are gaining popularity in snack and bakery applications

Bob’s Red Mill updates palletizing with Universal Robots cobot

Automated technology can help increase efficiency in snack and bakery warehouses

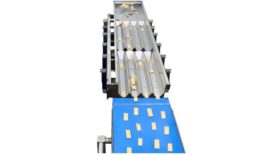

Key Technology introduces conveying systems for robotic pick-and-place packaging

Aptean shares insights on 2024 food industry trends in new report

Automated packaging tech helps streamline snack and bakery operations

Delkor Systems shares automation perspective on NBC Nightly News segment

IMAGE GALLERIES

New Processing Equipment: February 2021

Modernized bakeware including pans, tins, trays, and coatings, as well as automated pan handling systems.

New Processing Equipment: December 2020

Automation, ease of operation, simple cleanability, hygienic design, operator safety, and the ability to process nontraditional and healthier ingredients are among the top of mind requests for snack and bakery operators looking to buy or upgrade laminators or sheeters.

New Processing Equipment: September 2020

Bakeries and snack makers in the market for ovens, proofers, fryers, and dryers have a healthy list of features and benefits in mind. These include capabilities for customization and flexibility, reliability and consistency, temperature control, faster processing times and continuous production, and automation that operators can control and monitor remotely.

New Packaging Equipment: August 2020

The nature of snack and bakery operations poses challenges to manufacturers of robotics equipment. Space is an issue. Also, the equipment must be able to handle a wide range of products of different shapes and sizes at high speeds while not damaging the goods.

New Processing Equipment: February 2020

Customers of ingredient handling equipment are focused on a wide mix of factors to come up with their optimal formulation. These include accuracy, traceability, food safety, automation, cleanability, efficiency, flexibility, batch quality and fire safety, manufacturers say.

New Packaging Equipment: February 2020

The latest product handling equipment, cartoners, case erectors and packers, loaders and palletizers, features maximum flexibility in terms of product handling and packaging styles, which is good news for bakery and snack producers.

New Packaging Equipment: August 2019

New robotics technology is helping to improve primary and secondary packaging applications in snack food and wholesale bakery operations. Areas of innovation include end-of-arm tooling (EOAT), robot learning, sanitation and space optimization. Given the efficiency improvements robotics can bring to manufacturing—and the growing level of flexibility the technology now offers—its use is expanding.

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.png?height=168&t=1706135028&width=275)