ARTICLES

Top trends in snack and bakery packaging safety

New technologies keep goods fresh and extend shelf life

April 15, 2019

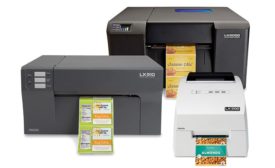

Advances in snack and bakery product labeling

New technology improves printing speed, accuracy and flexibility

March 15, 2019

Product handling for secondary packaging goes robotic

Flexible, automated systems reduce labor-intensive processes

February 7, 2019

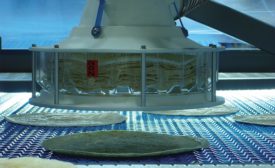

Inspection and detection equipment reach new levels of flexibility for peak food safety

X-ray, metal detection, checkweighing and vision systems help processors ensure food safety

January 8, 2019

Advanced secondary packaging solutions streamline distribution

Secondary packaging systems meet quick-changing market demands

December 10, 2018

New form/fill/seal equipment offers packaging flexibility

Machines accommodate a wide range of packaging options at high speeds.

November 8, 2018

Advanced packaging materials improve snack and bakery products

Consumer convenience, food safety, sustainability and desire for longer shelf life drive innovations

September 19, 2018

Innovations in fleet management offer improved technology and efficient vehicles

Routing and scheduling software and vehicle advances help deliver goods to market efficiently and on time

September 14, 2018

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing