Warehouse & Distribution

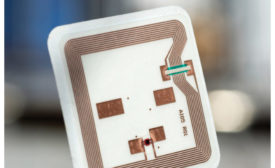

Modern-day inventory control concentrates on going paperless and increasing sustainability

Read More

Cold-chain management goes high-tech

New technology maintains and tracks temperatures throughout the supply chain

May 12, 2016

Technology’s new level of ingredient and product traceability

Software solutions help snack producers and bakers build a proven traceability plan to track ingredients and finished goods to prevent or handle product recalls.

April 15, 2016

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing