Trends

Better-for-you foods are getting the nod from consumers seeking to improve their overall health and well-being.

Read More

Way Better Snacks sets the pace for better-for-you snacking

Way Better Snacks builds momentum as a leader in better-for-you snacking, featuring a range of sprouted ingredients in its clean-label tortilla chips and crackers.

April 15, 2016

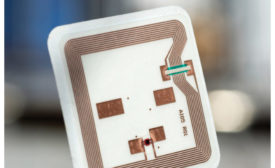

Technology’s new level of ingredient and product traceability

Software solutions help snack producers and bakers build a proven traceability plan to track ingredients and finished goods to prevent or handle product recalls.

April 15, 2016

Extrusion systems help bakers, snack manufacturers deliver on-trend products

Extrusion systems help bakers and snack manufacturers deliver the better-for-you products today’s health-conscious consumers want.

April 14, 2016

Today’s scales and checkweighers address bakers & snack manufacturers changing packaging needs

While ease of use and sanitation are primary considerations for bakers and snack producers when selecting a scale or checkweigher, new package sizes and the need

for data connectivity are also top of mind.

April 14, 2016

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing