Equipment

Snack and bakery production use IoT for food safety, as well as inspection and detection

Read More

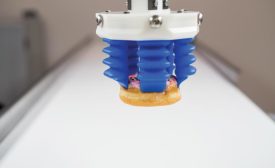

Adding automation to new and legacy snack and bakery production facilities

New and legacy snack and bakery production facilities can benefit from introducing strategic levels of automation

November 12, 2018

Automation, sanitation, safety, speed are top priorities for cutting, slicing and portioning equipment

Customers seek higher standards of automation, sanitation, and speed.

November 9, 2018

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing