Equipment

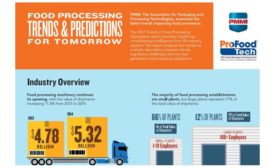

Infographic: Drivers change but food retains steady growth

Food processing infographic shows healthy and convenient food options are a top of mind consumer demand

February 21, 2017

Traceability provides transparency, clarity in the supply chain

New technologies help operations implement paperless traceability throughout a product’s life cycle.

February 15, 2017

Product handling equipment evolves to address product changeover, productivity

Product handling equipment goes robotic, offering flexibility and quick-change capabilities to create a wide range of packaging styles.

February 15, 2017

Ingredient handling equipment to maximize efficiency and throughput

Automated ingredient handling and connectivity help reduce waste while increasing throughput.

February 15, 2017

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing