Equipment

Hygienic design, quicker changeovers and reduced maintenance time are top benefits with new equipment

Read More

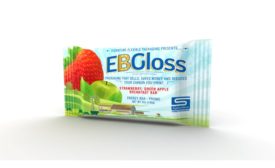

Packaging trends keep snacks and baked goods fresh and safe through shelf life

Modified-atmosphere solutions and active packaging technologies lead developments in packaging safety

April 10, 2018

Bakery snacks continue to innovate and grow through diversification

New flavors and more clean-label products rank high among trends related to doughnuts, pastries and muffins

April 6, 2018

Warehouse equipment aims to facilitate better storage and distribution

New warehouse equipment improves driver safety, visibility and maneuverability

April 5, 2018

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing