Equipment

Legacy snack and bakery facilities pose their fair share of sanitation challenges

Read More

Ingredient handling equipment helps snack and bakery companies improve efficiency and safety

Snack and bakery companies search for a variety of ingredient handling equipment

February 8, 2019

Product handling for secondary packaging goes robotic

Flexible, automated systems reduce labor-intensive processes

February 7, 2019

New and improved belts and conveyors for snack and bakery production facilities

Snack and bakery companies seek improvements to capacity, energy efficiency and safety in their belts and conveyors.

January 9, 2019

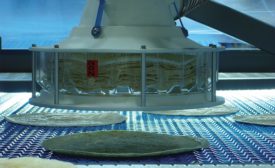

Inspection and detection equipment reach new levels of flexibility for peak food safety

X-ray, metal detection, checkweighing and vision systems help processors ensure food safety

January 8, 2019

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing