Home » flexible packaging

Articles Tagged with ''flexible packaging''

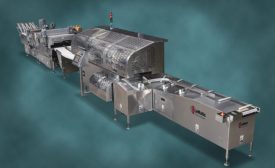

Higher production speeds and smaller footprints are among the latest features in closing and bagging equipment.

Read More

Packaging closure and equipment innovations address consumer food packaging concerns

As consumer demand for resealable, flexible packaging continues to grow, so do packaging closure and equipment innovations.

May 12, 2016

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing