Home » automation

Articles Tagged with ''automation''

Product handling for secondary packaging goes robotic

Flexible, automated systems reduce labor-intensive processes

February 7, 2019

Adding automation to new and legacy snack and bakery production facilities

New and legacy snack and bakery production facilities can benefit from introducing strategic levels of automation

November 12, 2018

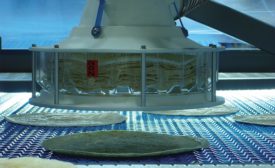

Automation, sanitation, safety, speed are top priorities for cutting, slicing and portioning equipment

Customers seek higher standards of automation, sanitation, and speed.

November 9, 2018

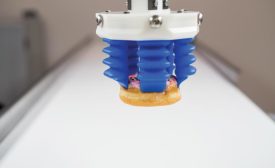

Robotics improve snack and bakery packaging operations

Advanced end-of-arm tooling, robot learning, sanitation and space optimization bring sophistication to packaging automation

August 10, 2018

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing