Snack and bakery producers face many challenges as they strive to staff their facilities, especially when it comes to operating packaging equipment. Finding and retaining skilled workers is a challenge as there is a learning curve associated with running complex packaging equipment. However, new smart packaging systems are available to help overcome these challenges. Robotics plays a significant role in these innovations.

As snack and bakery producers grapple with the challenge of hiring and retaining machine technicians, there have been notable shifts within packaging operations. With fewer skilled workers available, companies are requesting more solutions in machinery aimed at bridging this skills gap, according to Jorge Izquierdo, vice president of market development at PMMI. “This has led many companies to move away from training internal staff to service their machinery. Instead, they rely on machine builders to handle maintenance.”

Machine builders possess expertise with their own equipment and are uniquely positioned to offer maintenance services that ensure best performance, Izquierdo adds. “This shift has led many machine builders to introduce subscription-based preventative maintenance plans rather than offer services on an as-needed basis.”

To further address the labor issues faced by machine users, many manufacturers have expanded their service offerings to include: training and line-side support; ongoing training and on-site support; productivity reports; productivity assessments to identify areas where operators can improve efficiency and recommend best practices; and enhanced aftermarket services.

Cost, scarcity, and retention all present labor challenges to snack and bakery producers, according to John Weddleton, automation product manager at Harpak-ULMA Packaging. “Most young people joining the workforce are not looking for jobs in manufacturing, so it is important that we introduce new technologies in packaging and automation, such as AI- and IoT-enabled equipment that will make the jobs less manual and more interesting to them.”

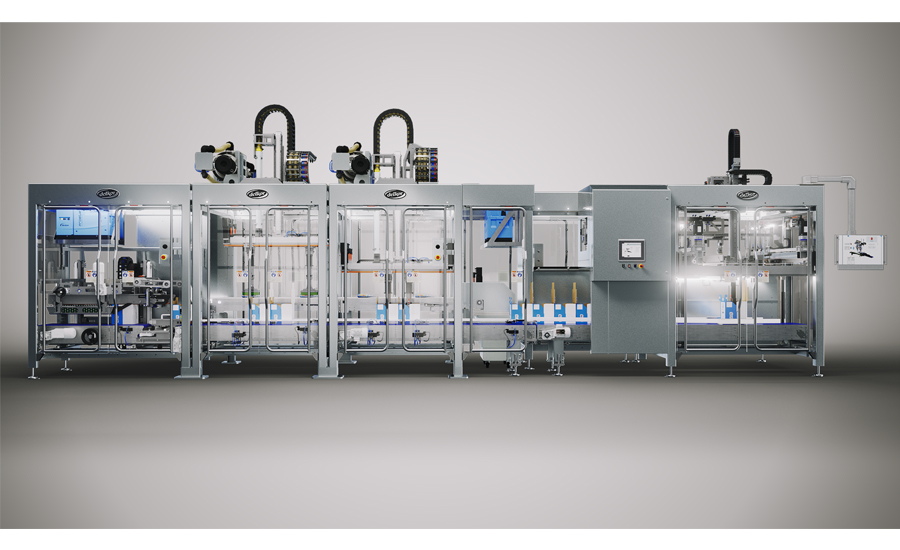

There are opportunities to save on labor costs during each step of the packaging process: primary feeding and loading, secondary cartoning/case packing, basket management, case erecting/closing, and palletizing, Weddleton adds. “Harpak-ULMA specializes in full-line packaging and automation. We provide a single source for an automated line and the ability to design, engineer, program, supply, integrate, install, train, and service equipment from product arrival through palletization.”

Dale Andersen, president and CEO at Delkor Systems, agrees that the new generation of packaging equipment needs to be smarter. To that end, Delkor Systems will introduce Rockwell Optix HMIs (human-machine interface) on all its machines at PACK EXPO, to be held November 3-6 in Chicago. “Our HMI control panel can inform the operator when problems occur and provide directions for correcting issues.”

One of the best ways to save on labor costs is to invest in packaging automation, which can reduce dependency on human labor and improve productivity, according to Luis Pilonieta, director of sales at Paxiom. “Paxiom offers integrated systems that combine multiple functions and components—such as conveyors, checkweighers, metal detectors, labelers, printers, coders, and scanners—to create a customized packaging line. These systems can be monitored by a central touch screen or a remote device, thus lowering labor costs.”

Increasing throughput can be critical for labor-saving, but in many cases efficiency and reliability are more important than speed, says Brantley Turner, global product line leader for VFFS and flow wrapping, BW Flexible Systems. “While we provide equipment to suit different speeds and levels of automation, we’re especially excited about the ease-of-use features on the R300, our new hand-fed flow wrapper.”

One key feature is the integration of advanced, yet accessible, technologies that simplify machine operation. “For example, the R300 is equipped with RFID (radio frequency identification) login systems that allow customized access to machine settings. By providing step-by-step instructions, our system simplifies the changeover process, allowing operators of all experience levels to quickly switch between SKUs (stock keeping units).”

To help snack and bakery producers save on labor costs, Syntegon offers fully automated packaging lines that can be seamlessly integrated with robotic solutions. “Our company offers equipment such as the vertical bagger SVX, the Pack 403 flow wrapper, and the Elematic case packer—all designed to optimize efficiency and reduce manual intervention. In fact, Syntegon specializes in turnkey packaging solutions,” says Jason D’Arcy, product group sales manager, vertical.

Bert Broos, director of packaging at Reiser, sees more packaging systems that have been used in fresh food industries being adopted by snack and bakery producers, especially for added-value products. “We supply thermoforming machines to bakers. Because loading product into the pack is easy, the packaging process requires less labor. At the same time, product integrity is guaranteed as the pack is hermetically closed in a sealing station within the machine.”

More recipes need to run on snack and bakery packaging equipment today with minimal changeover time between runs, notes Bob Murtagh, vice president of sales and marketing at Yeaman Packaging Systems, Lake Forest, Ill. “To that end, our equipment can perform analytics on the health of the machine, communicate these findings to management, and predict when components may fail. This allows companies to schedule maintenance and downtime, thus reducing labor costs.”

Delkor Systems recently introduced the EVO top load, vision-based robotic case packer, which combines high speeds and high payload capabilities—all while packing a variety of formats ranging from 4-inch-wide shelf-ready displays up to 1/4 pallet stackable trays, the company reports. Each cell occupies only 5 feet of length so an EVO case packer running 240 pouches per minute occupies just over 20 feet in length and 6 feet in width.

AFA Systems offers complete end-of-line packaging solutions: cartoning, case packing, and palletizing systems that can reach speeds of 300 cartons per minute on a single cartoner, according to Eric Langen, director sales and marketing. “This production level is not feasible for companies to handle with manual labor. Thus, our packaging solution can help businesses that are looking to expand their operations and reduce labor costs.”

Cama North America manufactures packaging equipment that generates ROI through labor savings, according to Billy Goodman, managing director. “The Cama robotic loading, cartoning, and case packing system is designed to automate secondary packaging operations. Depending on the speed, materials and pack configuration, our equipment can eliminate two to 20 people per shift. Also, Industry 4.0 technologies used on our equipment provide better training and diagnostic tools for operation and maintenance.”

Are many snack and bakery producers embracing these packaging innovations? Goodman says most producers are doing so, as long as they have the volume to support automation. “There remains trepidation by some producers, but after overcoming the initial implementation of packaging automation, there is typically eagerness to automate packaging operations.”

Langen says the biggest obstacle is cost because fully automated packaging lines are expensive. “Also, you need a different set of skilled employees to run and maintain automated packaging lines compared to manual operations. However, because speeds, changeover time, reliability, and flexibility are improving, the payback period is becoming shorter, making packaging automation a great return on investment.”

What new packaging technologies will help snack and bakery producers reduce labor costs in the near future? In addition to robotic solutions, digital monitoring tools like Syntegon’s Synexio, a cloud-based software solution, will play a crucial role in reducing labor costs, says D’Arcy. “These tools enable real-time error detection and collect production and machine data, which helps improve maintenance. In fact, the factory of the future is evolving to be smart and touchless, with technologies designed to support autonomous production, further reducing the need for manual intervention.”

Izquierdo says one possibility is the use of AI assistive technology on the HMI to support operators. “AI can enhance the HMI to assist line workers, similar to the way AI chatbot systems function today. A chat system could help workers troubleshoot tasks or gain assistance as needed. The system could streamline the process by reducing potential errors and guiding operators through troubleshooting steps.”