Brand owners in every consumer packaged goods (CPG) category continue seeking out and employing new materials in the ongoing effort to create a more sustainable package.

Candy is no exception, with many major candy producers instituting initiatives promising consumers 100 percent sustainability and the eventual elimination of virgin plastic. While Hershey set a target of 2030, Mars Wrigley, Nestlé and Ferrara are even more ambitious, pledging to only use completely sustainable packaging by 2025.

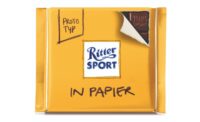

Bio-based polymer plastics receive most of the headlines as a potentially sustainable material solution. Still, a much more common substrate, paper, is finding acceptance in candy packaging at a more rapid pace. Paper is far more biodegradable than plastic and is easily recycled when placed in the proper channels.

With any change to a package or package format, however, there are hurdles that CPGs must consider and overcome to reach these goals, whether it be cost or production speeds. When considering a change, material suppliers and original equipment manufacturers (OEMs) need to be included as early as possible in the process to test new materials and suggest solutions for machine modifications or alterations. A recent example of this type of necessary synergy is taking place in Germany involving Mars Wrigley and Syntegon Technology, the OEM formerly known as Bosch Packaging.

Syntegon, understanding the growing desire from global companies to become more sustainable, began working a few years ago on retrofit kits for application on its horizontal flow wrapping machines. These tools allowed the reconfiguration of existing machines that typically wrapped chocolate bars in plastic to more sustainable films and materials, including paper. Knowing this new solution was available, Mars Wrigley sought out the right material to test run on one of its products. The multinational company chose Balisto chocolate bars for the pilot program because the bar contains chocolate and a biscuit, ensuring the need for a moisture barrier.

After testing multiple paper-based materials, Syntegon learned more about what its machines could and couldn’t convert, as well as tweaks necessary for different materials. For Mars Wrigley, the program allowed it to release Balisto bars across Germany in paper-based packaging to determine how the new packaging material holds up in production, delivery, retail and finally in the hands of consumers. The program is ongoing, but Mars Wrigley reports positive results so far.

Nestlé also made the paper-based package switch for its Smarties chocolate candies, moving over 400 SKUs of the brand from plastic to paper, including paper-based tubes, small cartons, stand-up pouches and paper bags.

With so many different packages in play, the move from plastic packaging, comprised of multiple layers of film, to paper was no small feat. The final material is a proprietary paper structure from sustainable sources. Like Mars Wrigley, Nestlé worked with its OEMs to modify existing equipment to ensure the paper-based materials would hold up at high speeds. Nestlé also took advantage of the change to use the packaging as a promotion tool for good recycling behavior to instill this in the young children, who represent a large portion of their target demographic.

When considering a switch to a more sustainable packaging solution, collaborating with suppliers is key to success. To properly assess potential solutions, it is critical to see packaging technology firsthand and talk with the suppliers face to face, making PACK EXPO East (March 21-23, 2022; Pennsylvania Convention Center), an ideal place to make these connections. With 400 exhibitors, PACK EXPO East provides a convenient and rewarding opportunity for consumer packaged goods (CPG) and life sciences professionals to explore packaging and processing technology, connect with suppliers and find the solutions needed to compete in a changing marketplace. To register or learn more, visit packexpoeast.com. For information about the PACK Ready Health and Safety plan, visit packexpoeast.com/packready.