Photo Galleries

New Packaging Equipment: March 2021

New research and innovations in packaging materials are focused on sustainability, which is important for bakery and snack producers who strive to achieve green solutions in their everyday packaging operations. Sustainability also is a key concern for consumers who prefer materials made from recycled materials.

New Packaging Equipment: February 2021

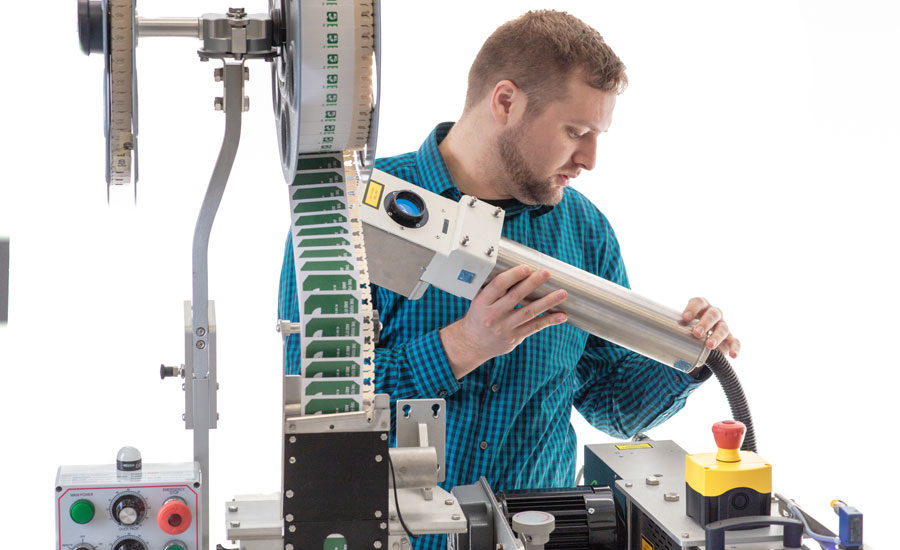

The latest trends in labeling for bakery and snack producers involve advances in printers, software, inks, and marking/coding technology.

New Packaging Equipment: January 2021

The latest X-ray, metal detection, checkweighing, and vision systems feature multi-scanning capabilities, machine connectivity, and improved operator learning tools. These upgrades allow the equipment to better detect small foreign objects, reduce false rejects, and handle a wide range of products to ensure maximum food safety. Bakery and snack producers use inspection and detection equipment to improve their quality control and food safety programs.

New Packaging Equipment: December 2020

The latest advances in convenience packaging options, single-serve, re-sealable, portion-controlled, on-the-go, offer retailers and consumers greater convenience, reliable containment, and sustained freshness. Increased recyclability and sustainability are other features. This is good news for bakery and snack producers who are striving to meet consumer demand.

New Packaging Equipment: November 2020

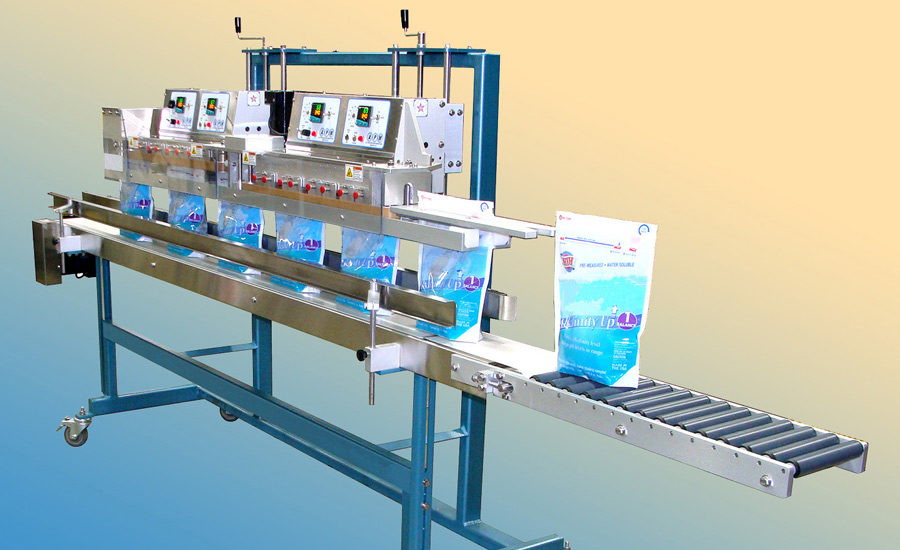

Consumer trends are driving bakery/snack production in the areas that form/fill/seal (FFS) systems accommodate. The types of packaging formats being requested by retailers and consumers is a major factor. As a result, the latest FFS systems can produce single-serve, portion-controlled packs at high speeds while offering quick changeover.

New Packaging Equipment: September 2020

Advances in packaging materials continue to extend shelf life, while adding convenience and freshness to bakery and snack goods. Innovations in modified-atmosphere packaging (MAP), microbial-inhibiting film, and the use of cellulose nanocrystals are helping to push the envelope.

New Packaging Equipment: August 2020

The nature of snack and bakery operations poses challenges to manufacturers of robotics equipment. Space is an issue. Also, the equipment must be able to handle a wide range of products of different shapes and sizes at high speeds while not damaging the goods.

New Packaging Equipment: May 2020

A desire for sustainability is one of the key factors driving the latest packaging innovations in baggers, closing equipment, twist ties, clips, zippers, resealable materials, heat sealing, and ultrasonic sealing.

New Packaging Equipment: April 2020

Manufacturers and researchers worldwide are striving to develop new ways to keep snack and bakery products safe and fresh over the course of their intended shelf life.

New Packaging Equipment: February 2020

The latest product handling equipment, cartoners, case erectors and packers, loaders and palletizers, features maximum flexibility in terms of product handling and packaging styles, which is good news for bakery and snack producers.

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing