New Equipment

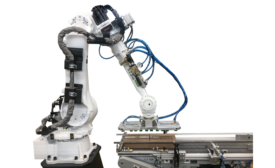

Snack and bakery companies search for new features in ingredient handling equipment

Automation, food safety, adaptability in the ingredient handling mix.

May 21, 2021

New, improved mixers for snack and bakery dough applications

Mixer customers want pre-hydration, automation, sanitation.

April 28, 2021

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing