Home » bagging equipment

Articles Tagged with ''bagging equipment''

Product introductions feature a wide range of features.

Read More

Integrating sustainable packaging for on-the-go snacks

Closing and bagging product introductions feature a wide range of features.

May 28, 2021

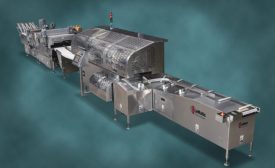

Innovations in bagging and closing equipment for snacks and baked goods

Upgrades include efficiency, hygienic design, smart technology and sustainability.

May 17, 2019

The evolution of closing and bagging equipment for snacks and baked goods

Higher production speeds and smaller footprints are among the latest features in closing and bagging equipment.

May 15, 2018

Snack on the latest trends, news, and developments!

Stay in the know with Snack Food & Wholesale Bakery, the premier source of information for snack, bakery, and confectionery professionals.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing