For more than 80 years Aasted has been known as the leader in innovative tempering technology and high quality machines.

For more than 80 years Aasted has been known as the leader in innovative tempering technology and high quality machines.

The company’s latest energy tempering technology breakthrough — which has been developed and tested for more than two years — is a groundbreaking debut that saves at least 50% in total energy consumption in comparison with traditional tempering machines.

Aasted’s SuperNova Energy machines are smaller in size and weight than traditional tempering machines. Moreover, the energy tempering technology raises the quality of the tempered chocolate to an unprecedentedly high level and even enables handling of high-fat content masses without a decrease in capacity.

The secret is the crystallization technology

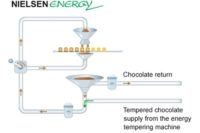

The new groundbreaking energy crystallization process inside is the secret to energy savings. The considerably longer time that the mass is in the crystallization zone, the greater an impact the SuperNova Energy’s unique scraper wings and precise temperature control contribute to realizing this ingenious solution.

It’s really a back-to-basics tempering technology (marble plate method) that achieves this quality breakthrough:

The longer crystallization period of stable crystals combined with the avoidance of unstable crystals provides the longest possible shelf-life for chocolate products.

Unforeseen production flexibility

In addition, the nominal capacity of the machine can be controlled from 25 to 110%, resulting in higher production flexibility. The SuperNova Energy tempering machine has the ability to handle all temperable chocolate and filling masses.

In addition, a new operator interface makes running the unit more intuitive . This, together with the new screen design featuring "Temperature Indicator Bars," ensures that — even from a distance —an operator can see whether the machine is running properly by a mere color mode change. A new “service Indicator” also informs operator when it is time for service.

The new SuperNova Energy line represents a range of "green" tempering machines that supply customers with the high quality tempering while simultaneously delivering savings between 50% to 80% in total energy consumption.

For more information, visit www.aasted.eu