Innovation, much less breakthrough innovation, remains an ongoing challenge for suppliers to the confectionery industry.

Typically, breakthroughs only occur when engineers re-examine past approaches and literally discard traditional thinking. Oftentimes, this disattachment reveals a simpler, more efficient, more environmentally benign solution to a processing operation.

Farum, Denmark-based Aasted proudly unveils such a breakthrough in enrobing, one that involves inventing a new way to feed chocolate into the enrobing machine. It allows a constant stable tempering index and temperature in the chocolate mass.

In doing so, the process delivers not only energy savings, but a more homogeneous production with less solidification of the mass in the enrober.

The patent-pending process, delivers the following benefits:

► A more uniform chocolate mass with homogeneous tempering index stabilizing the enrobing machine.

► Less feeding of the chocolate mass from the tempering machine, which enables use of a smaller tempering machine, thus ensuring savings of energy. This, in turn reduces investment and energy costs.

► The enrobing machine can run longer because of less solidification of the chocolate mass in the enrober. Less down time, coupled with reduced product waste, delivers more efficient production cycles.

► Less chocolate is returned to the tempering machine, ensuring more energy savings.

All these factors contribute to a better and more homogenous final enrobed product of a uniform quality. The homogeneous enrobing, the stabilized temperature and tempering index and the reduced product waste saves both time and money.

How does it work?

The Energy Enrobing Concept works by a direct injection of the tempered chocolate mass from the tempering machine to the consumption flow, compared with traditional enrobing machines, where the tempered chocolate is mixed with the chocolate in the service tank .

Direct injection of finished tempered chocolate mass ensures a homogenous tempered mass, which will result in a uniform tempering index in the enrober with constant temperature resulting in improved finished products.

Creating the optimal enrobing circuit

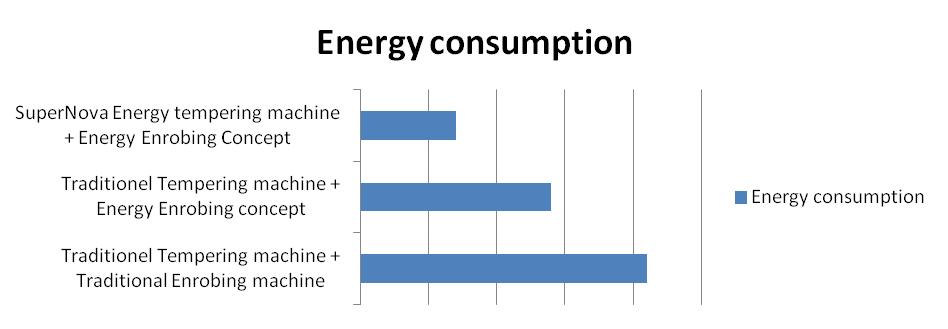

A combination of the Aasted Energy Enrobing Concept with an Aasted SuperNova Energy tempering machine enables chocolate manufacturers to save up to 2/3 kW consumption compared with traditional tempering machines and traditional enrobers.

Choosing to optimize your enrobing circuit with the SuperNova Energy tempering machine as well as the new Aasted Energy Enrobing Concept will boost energy savings by ensuring:

► Improved floating ability in the chocolate mass

► A stable Beta 5 crystallization process and a homogenous tempered mass

► Reduction of cooling time in the cooling tunnel

After trials at Aasted’s Technology Center with the Energy Enrobing Concept , which included a SuperNova Energy tempering machine in the circuit, the testing produced the following results:

|

With these illustrations we want to show the difference within the enrobing circuit between a traditional enrobing machine and the Aasted Energy Enrobing Concept.

The drawing above illustrates the traditional enrobing machine with the chocolate mass feeding from the tempering machine and mixed into the service tank with the result of a heterogeneous chocolate mass.

The drawing below illustrates the Energy enrobing concept with the chocolate mass feeding directly injected to the consumption flow to ensure a constant flow of finished tempered chocolate mass.

|