Hebenstreit supplies production systems for flat and hollow

wafers that range from semi-automatic lines with a capacity of about 120 kg/h

to fully automatic, high-efficiency lines rated at 1,200 kg/h and more.

The extent of the product range begins with raw material

dosing and mixing systems for the preparation of wafer batters and extends to

the fully automatic conveying of the cut, cream-filled wafers to subsequent packaging machines,

coating plants or moulding lines.

As early as 1898, baking machines were manufactured in the

factory in Radebeul near Dresden.

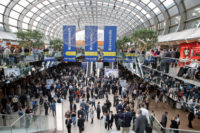

However, since the company’s re-incorporation in 1950, the headquarters are now

located in a nearby suburb of Frankfurt/Main, Germany.

Many high-profile

companies form part of Hebenstreit’s clientele, with the world’s most popular wafer products produced on its

systems.

Each wafer production system is “tailor-made” according to

the individual requirements of the customer. They are designed depending on the

type of product required, capacity, grade of automation and existing production

facilities. In addition, high-quality products in many cases demand the

development of custom-engineered machines.

As a matter of principle, maximum operating safety and the

incorporation of the latest technological improvement - be they mechanical or electrical - remain

critical components of every Hebenstreit production system.

Such continual self-improvement minimizes “down time.” For example,

all clutch/brake units have been replaced by frequency-controlled drives or

servo drives. Consequently, production interruptions because of maintenance

requirements or normal wear and tear are minimized.

Hebenstreit guarantees excellence post-sales service,

supported by a network of more than 60 representatives worldwide, as well as 25

highly experienced service engineers.

For more information, visit www.hebenstreit.de

At Upakovka, come by booth 22B-02, hall 2.2; at interpack,

booth E-08/12, hall 3.

Petzholdt-Heidenauer Maschinen- und Anlagenbau International GmbH has

been developing and manufacturing special machines for cocoa processing and

chocolate mass production for more than 170 years. It is one of the leading manufacturers of

five-roll refiners in the field of chocolate mass production.

With

innovations, such as our fineness measuring device HMB, the company has enabled

its customers to use five-roll refiners at higher levels of automation and

efficiency as well as providing even more uniform results. The company’s line

of HFS180S five-roll refiners have attained noticeable increases in output.

Typically, fineness

and throughput depend on the size of the last gap and the transport rate of

speed through that gap. By retaining the same size fineness on the same final

gap, increased throughput can be achieved by increasing the width of the roll

or by increasing the transport rate of speed through the final gap.

An increase

of roll width means, aside from increased space requirement, reduced mechanical

rigidity of the rolls and thus possible limitations in the range of recipes and

the fineness grades that can be processed.

The

transport rate of speed may be increased by using a higher rotation speed or by

increasing the diameter of the roll. The rotation speed cannot be increased

significantly beyond today’s usual levels because of increasing centrifugal

forces and the resulting increased spin-off of chocolate mass particles from

the roll surface, as well as the thermal stability of the rolls.

An increase

of the roll diameters, on the other hand, allows higher transport rates of

speed in the final gap, i.e. higher throughput while simultaneously limiting

centrifugal forces to a level more compatible with refining of chocolate mass.

Thus, a larger roll diameter has a positive impact on thermal conditions, among

other things, because of the larger roll surface area for cooling, as well as

the mechanical stability of the rolls.

The

footprint and, thus the required floor space, is the same as that of our familiar

HFS five-roll refiners, which facilitates the replacement of existing machinery

with the same working width in the same place without any problem.

Using the

same floor space and with a machine height increased by just 200 mm, our new

HFS Super five-roll refiners achieve a significantly higher throughput at

unchanged rates of fineness compared to our previous HFS refiners.

For more

information, visit www.petzholdtheidenauer.de

At

interpack, come by booth E-07, hall 3,

The name Rose has been famous in the packaging industry

since William Rose first patented his design for a tobacco-wrapping machine in

the 1880’s. Today, more than 100 years later, A.M.P-Rose

is still manufacturing high-speed packaging machines in William’s home town of Gainsborough, England.

A.M.Packaging Ltd. began as a supplier of rebuilt candy

wrapping machines in 1978. Back then, the company employed four engineers in a

small factory. The founder, Alan Mann, had learned his trade as a Rose

technician from the age of 16.

The business expanded to such an extent

that in 1990 A.M.P was able to purchase the Rose and Forgrove confectionery

businesses and at that time re-named itself A.M.P-Rose.

Since its humble beginnings, the company has developed into

one of the world’s leading suppliers of machines to the chocolate and confectionery

industries, with 75% of its products being exported to more than 80 countries

worldwide.

The company’s current products and services can be summarized

as follows:

New

machines

Cut and wrap machines for toffees, chews and

gum, with speeds of 1,000 pieces/minute.

Continuous

hard candy and caramel cooking systems up to 1,500 kgs/hr.

Candy-forming

equipment for hard-boiled sweets and toffee éclairs.

Pre-formed candy twist- and pillow-wrapping machines.

Coating systems for hard and soft panning.

Chocolate bunch and twist wrapping machines

Used

and rebuilt machines

The A.M.P Rose name also is synonymous with the supply of

high-quality rebuilt confectionery and chocolate processing and packaging

machinery. A fully rebuilt machine from

A.M.P-Rose has a 12-month parts and labor guarantee.

Our engineers are experienced with many different brands of

processing and packaging machines, which allows us to supply almost any machine

required in the candy manufacturing process.

Spare

parts and service

The company has a well-equipped machine shop capable of

producing a wide range of engineering components attaining the highest degrees

of accuracy. A.M.P.-Rose supplies spare parts for all Rose and Forgrove candy

machines as well as parts for many other makes of machines, including

size-change parts, replacement knives, cams, gears etc.

Our experienced service technicians regularly install and

commission our equipment all over the world. A visit to the company’s headquarters in Gainsborough, England,

is highly recommended. Customers can see 30-year-old wrapping machines being

rebuilt as well as the latest in new machinery incorporating modern PLC and

servo-drive technology.

For more information, visit www.amp.rose.com

At interpack, come by booth E-39, hall 3.

Caotech b.v., based in Wormerveer - the Netherlands, has a worldwide

reputation as specialist in self-developed ball mills and conches within the

cocoa and chocolate-related processing sector. At Upakovka, Caotech will be

pleased to discuss the latest developments on cocoa, chocolate and compound

processing.

Drawing

upon years of expertise in conjunction with its extensive field experience, the

company recently launched a number of developments in the field of cocoa,

chocolate and compound applications.

Traditionally

Caotech’s scope of supply covers a wide variety of installations, varying from

a small, lab-size ball mill to a conche type CAO B5 & W5, from the well-known CAO B3000-CHOC

batch installation to the CAO 3000 In-Line as a component in a continuous

production line for both cocoa and chocolate or as a complete turnkey project.

As

pictured, the company’s sophisticated CAO 3000-CHOC IN-LINE installation is a

fully automated processing line for the production of chocolate and compound

with capacities of up to 2,000 kg per hour. Depending upon customer’s

requirements, the line can be completed with ingredient dosing and weighing

sections.

Recently Caotech has developed an alternative continuous

conching unit to be used as a wet conching system. This CWC 2000 (Continuous

Wet Conche) can be placed behind traditional conches for final homogenization

and conching, as well behind ball mill systems for obtaining a high quality

chocolate.

At the

Upakovka, Jan Hammink will be pleased to receive visitors at the booth of Anton

Ohlert to discuss plans related to compound, chocolate and cocoa processing.

At

Upakovka, come by booth C-02, hall 2.2; at interpack booth C24/26, hall 3.

Hosokawa

Bepex, based in Leingarten,

Germany, is a

well known supplier of specialized equipment used in confectionery processing.

It has developed a high degree of competency involving mass preparation,

forming, pre-cooling, cutting and depositing as well as enrobing and final

cooling.

Hosokawa Bepex GmbH, whose history

encompasses 60 years of processing experience and know-how, is positioned as a

leading source of confectionery production equipment and complete processing

lines.

Equipment

and production lines for any type of confectionery products can be designed and

supplied, starting from raw materials handling up to the desired finished

product.

In its

recently opened new technology center, the company can demonstrate complete

processes, including Ter Braak cooking, Bepex forming and cutting as well as

Kreuter enrobing, tempering and cooling technology on 2,500 sq. meters.

Ter Braak, Bepex-Hutt and Kreuter

customers are now able to test the extensive range of equipment of these brands

under one roof in modern facilities. Besides test and demonstration facilities,

a level dedicated to factory acceptance tests of lines with the customer’s

final product was created.

For more information, click on www.BepexHosokawa.com

The evolution of Carle &

Montanari (SACMI Group) continues with new integrated solutions for the

chocolate industry, from cocoa processing to chocolate mass preparation,

moulding and packaging. At interpack 2011, the company will also debut its T-PACK2

electronic wrapper for chocolate bars and tablets.

The new machine is designed to

reach 200 ppm wrapping speed and can manipulate chocolate bars and tablets

ranging from 100 to 300 grams. The hermetically closed packaging, with internal

heat-sealed aluminum and external folded paper, guarantees the highest product

quality.

Other innovative solutions that

were recently introduced by the company include the following:

• The CAVEMIL “R” new family of

moulding lines, featuring an impressive flexibility and an innovative moulds

movement technology. This new line allows customers to maximize production by

using moulds of different sizes (for eggs, bar and pralines) on the same

moulding line.

• The sixth series of the MLR rotary depositors and the latest

version of the MEP piston depositor,

with removable head execution, represent the company’s newest line of chocolate

depositors. Available from 275 mm to 1,700 mm dosable surfaces, all of the

depositors are universal, which enable all dosing technologies (points, ribbon,

one-shot points and one-shot ribbon). Multi-head versions (Multicenter) are available for triple-shot and co-depositing

capabilities.

• The new BV Counter-moulds Buffering System, FIFO

(first in, first out) buffer for moulding lines, help customers efficiently

handle micro-stops of their packaging lines during production runs.

The new buffer offers an entirely

new way of stocking products directly on their demoulding counter-plates. In

addition to tablets, bars and pralines, the system can buffer book-moulded

products such as eggs, various moulded shapes and balls.

When the packaging line

re-starts, the stocked counter-moulds filled with products are sent to

packaging, while empty counter-moulds replace them in the buffering cabinet.

• Since the

successful debut of the new HFI series

of five-roll refiners two years ago, the company has expanded the line’s range

with a HFI 525 that features a 2,500-mm

roll length with an output of 1,600 kg/h of refined chocolate. The new machine goes to extend the

range of Carle & Montanari existing refiners, including the HFI518 (1800mm)

and the HFI513 (1300mm).

• Carle & Montanari’s legacy and experience in the manufacturing of

cocoa presses continues with ongoing technological developments, providing

innovative solutions to further increase the performance of the POV series machines and their ancillary

equipment.

• During

its 100 years of existence, Carle & Montanari has produced more than 1,500

moulding lines, many of which are still in production. Consequently, the

company has decided to allocate several resources and a dedicated team of

people to improve and extend the life of these existing moulding lines, improving products quality and introduce higher

flexibility and new categories of products.

At interpack, come by booth E-31/F-36, hall 3.

Klöckner

Hänsel Processing GmbH (KHP), whose heritage evolved from the famed German

company, Otto Hänsel, was founded in 1911. For nearly a century, KHP has

combined both expertise and experience in supplying confectionery processing

equipment, making it one of the few companies capable of successfully merging

talent and tradition for such an extended period of time in this field. The

company has a worldwide operation, backed-up by a strong net of agencies and

well-supported by excellently skilled regional sales managers at the main

office in Hanover, Germany.

About 90 % of the company’s

activities come from supplying processing machinery capable of producing virtually every kind of sugar

confectionery product:

Hard

Candy (center-filled, aerated,

laminated, milky, sugar-free, medicated, specialities)

Jelly

& Fondant (gelatin, agar agar, pectin, gum

arabic, starch, fondant crème, bakery fondant, milk fondant, fruit fondant)

Toffee

(milk caramel, éclair, fruit

candies, chewy candies, caramel layers, specialities)

Bar (foam sugar, candy bars, granola, torrone,

halwa)

In its technological CandyLab in Hanover,

KHP brings customers’ ideas about confectionery production into life. The

laboratory is equipped with industrial confectionery machines. In the CandyLab,

where KHP tests it own machine developments, the company always prioritizes customer

request first involving product development and testing.

KHP offers its “sweet competence” to customers with a processing chain that

begins with the most modern machine

technology derived from ongoing dedicated research and development to outstanding

service performance.

That development continues at KHP, where the final touches are being put

on new machines and processing lines that will be shown at interpack in

Düsseldorf in May, coinciding with the company’s 100th anniversary

celebration.

For more information, visit www.kloeckner-haensel.com

At Upakovka stop by booth 1B-34, hall 2; at interpack, booth A-25, hall

4.

Tanis Confectionery, a member of

the Tanis Group, designs and supplies lines for the production of sugar

confectionery. Tanis Confectionery knows the craft of confectionery inside out,

thereby mastering every detail of the production process. That’s why we remain

one step ahead. We don’t just come up with the technical know-how, we also have

the vision to create an entire production process. From design through to

finished product, we are proud of our reputation as process designers!

T-Rock

The Tanis Group has worked on the development of a new line for hard candy

processing during the past three years. Several configurations can be chosen,

all depending on capacity, recipe requirements and type of forming, die-formed

or deposited.

T-Gel Batch

Tanis Confectionery has launched a new solution to manufacture gums, jellies,

pastilles, creams and other starch-moulded products.

T-Gel Batch

Is based on simplicity,

flexibility and state-of-the-art process controls for a reduced budget. The

concept, developed for the cost effective introduction of new lines, can easily

be extended to accommodate higher volumes and a wider diversity of products

depending upon demand, with capacities ranging from 500 to 3500 kg/h.

Tanis Kitchen

In

"The Tanis Kitchen" it is possible to test your recipe on Tanis-designed

and -produced machines. For this we can choose existing equipment that’s

connected on-site as a standard solution, which may be best way to produce a

customer’s candy. It also is possible to combine equipment in new

configurations to create NEW

solutions for NEW products with NEW

flavors, combinations and shapes. of the ordered line or lines is as short and

efficient as possible, the company can run tests with supervisors /operators in

the Tanis Kitchen with a set-up similar to the line to be supplied. This

facilitates establishing process parameters in advance.

The Tanis Group offers also lines for caramel (T-Brown) , chewy (T-Chew), fondant (T-Cream), bar lines (T-Bar),

jelly lines, (T-Gel) and hard candies

(T-Rock) .

For more information, visit www.TheTanisGroup.com

At Upakovka, come by booth 22

A-02 in hall 2.2; at interpack, booth B-29, hall 3.

Confectionery products, traditionally indulgent treats, face

growing demands today from consumers to provide nutritional and health benefits

as well as indulgent satisfaction. Consumers are increasingly aware of the need

to reduce sugar intake and increase their intake of fiber.

Traditionally fiber has not normally been considered as an

option for indulgent sweets, but with recent developments in soluble fiber

technology, this is no longer the case.

Roquette’s confectionery division offers ingredients, such

as SweetPearl maltitol and NUTRIOSE soluble fiber, for making

indulgent confections that are reduced sugar, no-sugar-added or sugar-free

while delivering the health benefits of added fiber.

NUTRIOSE can replace corn syrup in most confectionery

applications to produce both reduced sugar (NUTRIOSE/sucrose) and

sugar-free (NUTRIOSE/maltitol) confectionery products. In addition to

reducing sugar, NUTRIOSE also provides dietary fiber to your

applications

It is an excellent ingredient for making better-for-you hard

candies, being both heat stable to 350ºF and also acid stable down to pH 3.0.

This also ensures compatibility in acidic fruit-flavored candies with no loss

of fiber and without compromising taste. Its high solubility is only limited by

its viscosity (~100mPas @ 50% DS),

which is relatively low and makes it useable at high levels.

SweetPearl maltitol is the sugar substitute known for

being 90% as sweet as sucrose and easy to use in complete or partial

replacement of sucrose. In result, this ingredient may be used to make great

tasting sugar-free, no-sugar-added and reduced-sugar chocolate and compound

coatings as well as confectionary products such as chewing gum and hard –

boiled sweets.

SweetPearl - the

maltitol by Roquette – which comes from cereal sources, combines pleasure with

well-being: it has exceptional taste, contains few calories and doesn't require

added sugars and is even good for your teeth.

SweetPearl maltitol enhances and accentuates the flavor of each

ingredients, offering richer, more surprising and delightful taste sensation

for the taste buds. It’s no wonder why many leading manufacturers, artisans and

even top chefs are already using SweetPearl

for their own culinary creations!

For

more information, visit www.roquette.com

As the global leader in food and beverage color technologies,

Sensient’s mission is to apply our long-standing expertise and unrivaled color

science to deliver unique, industry-defining solutions that are healthy, safe,

and secure.

Because Sensient’s expertise

encompasses a worldwide marketplace, we apply a unique perspective to natural

color formulation, delivering new opportunities in the confectionery industry.

Expansive consumer and industry knowledge fuels our vast technical

capabilities, translating into more unique and proprietary ideas and solutions

for our customers.

We continually make significant investments in the natural

colors market in order to acquire cutting-edge resources, resulting in clean

label options for confectionery markets.

A fully customizable safe and secure natural color solution, Fusion Precise Natural Colors is at the

forefront of the natural ingredient movement and is characterized by superior

consistency and stability, as well as an extensive color spectrum.

The Fusion Precise Natural

Colors line is brand defining, backed by unsurpassed trend knowledge and

consumer market insights. We help to protect brands by delivering a consistent

vibrancy, derived through nature and science for jellied candy, hard candy,

pan-coated candy, direct-compression tablets, chewing gum, and candy wafers.

The products in our Fusion

Precise Natural Color line are complete emulsions, dispersions, dry blends

or soluble systems that are formulated to meet global regulatory requirements

specific to your project.

Another Sensient Food Colors’ innovation, Spectra-Flecks adds aesthetic interest to confectionery

products. These flecks of color provide

visual differentiation through colored shapes to develop existing brands or

line extensions. Spectra-Flecks are

available using natural color and can be flavored for additional sensory

impact. Offered in various shapes to give products a unique, eye-catching burst

of color and visual distinction, Spectra-Flecks

will help products stand out on the shelves.

Sensient also offers a complete portfolio of natural color

building blocks like carotenoids and anthocyanins, which capture many of the

healthy attributes inherent in colors derived from fruits and vegetables, such

as antioxidants, vitamins, and polyphenols. Our worldwide reach allows us to

secure the safest supply of ingredients, encouraging confidence in all our food

colors.

Ensuring our customers have the widest selection of products, we

deliver cost-effective, highly concentrated forms of all exempt from

certification colorants. Creatively combining these foundational colorants into

natural color systems allows us to formulate broad shade ranges and product

performance attributes based on our customer’s exacting specifications. In

addition to providing colors to the United States’ palette, we offer

additional global options, such as chlorophyll, gardenia, iron oxides, carbon

black, spirulina, and non-titanium dioxide based white colorants.

For more information, visit www.sensientfoodcolors.com

Union Confectionery Machinery Co., a fourth-generation, family-owned business since 1912, is the world’s largest supplier of second-hand, used and rebuilt machinery for the confectionery, food, packaging, processing and biscuit industries. Our firm’s world headquarters are located in New York and consist of a 270,000-sq.-ft. building that contains sales and executive offices, a full rebuilding facility, massive warehousing and shipping and receiving areas. We also operate a similar plant in Mexico.

Our customer base is worldwide and encompasses a wide range of clients from Fortune 100 firms to small and mid-sized, family-owned and corporate entities. Union can supply modern used and rebuilt machinery solutions for manufacturers in many different fields including chocolate production, sugar confectionery, biscuit and general packaging applications.

We are major suppliers of quality equipment from well-known Original Equipment Manufacturers’ (OEM)s such as SIG/Sapal, Bosch, APV Baker, ACMA/GD, Rasch, Klöckner Hänsel and many others.

We can supply everything from an individual machine to a complete turnkey plant while offering technical assistance for plant design, formulation and general engineering. Our rebuilding facility is the largest in the world among used equipment dealers and our staff, many of whom have worked for the company for more than twenty years, is well trained in sales support, engineering, mechanical repairs, electrical upgrades and PLC programming.

Union offers different levels of rebuilding capabilities, including the delivery of equipment in working order to complete refurbishment with lengthy guarantees against the work performed. Each project is unique and treated as such to tailor customer requirements to the individual job.

Union can also rebuild worn and idle equipment sent in from the field on a contract basis. A full analysis of the equipment is performed before work is initiated and pricing is established. This process ensures complete agreement, and eventual satisfaction, for both parties.

Among our many other services, Union is the world leader in the appraisal, auction and liquidation of idle and redundant plants worldwide. We can help you to recover your investment from an individual idle or redundant machine to a complete turnkey plant. We have conducted sales of this nature in almost every country in the world.

Our greatest assets are knowledge and experience and we realize that our worldwide customer base is always in need of information. That is why we have built the world’s largest electronic database and incorporated our inventory, as well as other sales activities, into our world-class website.

Visit our web site to view photos and descriptions of our 25,000+ stock inventory of machinery, to see a list of our active auctions and liquidations and to learn more about our history and the services we provide.

As a fourth generation, family-owned concern, we understand the need for quality, service and fast accurate response and we continue to travel the world to service our clients.

For further information, visit www.unionmachinery.com

At interpack, come by booth E/03, hall 1.

Original Gourmet Food Co.

Original Gourmet

Food Co.’s patented and state-of-the-art “Candy Cooker” lollipop production

line features the lastest in cutting edge technology, revolutionizing the way lollipops

are made and marketed for years to come.

This customized

“Candy Cooker” is the first deposited candy line of its kind. Noticeably

different, the new Original Gourmet Lollipop has a transparent crystal-like

appearance unlike the standard lollipop seen in the market place with sharp

edges and cloudy centers. This amazing new look makes it fun and colorful for

everyone to enjoy.

Our customer service

department’s lines have been ringing off the hook with all the excitement. They are telling us that children enjoy them,

taking them to the movies, sporting events, and parties or just playing with

friends. Not only are the lollipops fun and colorful, they deliver great taste

with new intensified flavors such as Cotton Candy, Bubble Gum, Cherry and many

others.

Adults have also

found them to be a great low calorie snack; others use them as a smart

replacement for a for their nicotine addictions. More sophisticated flavors

such as Pina Colada, Banana Split and Raspberry Pomegranate - among others -

appeal to adult tastes. Moreover, the lollipops contain only 110 calories and

last almost one hour.

With the

introduction of our new state-of-the-art technology comes new varieties of

Original Gourmet Lollipops. We have

developed a formulation that blends the richest flavors with cream and creates

smooth tasting Original Gourmet Cream Swirls Lollipops. Our new hot flavors are Strawberry Shortcake,

Root Bear Float, Mocha Latte, with many more to come. All these launches

reflect the innovation that drives this company. Expect more of the same this

year.

Join in on the

lollipop phenomenon. Original Gourmet Food Co. has made a substantial

investment in creating fun flavors and colorful lollipops to become the No. 1

leader in the category.

We are on target to

becoming the “World’s Best Gourmet Lollipop,” We are also proud to say that our

quality Gourmet Lollipops are manufactured in the United States.

In the words of the company’s ceo, Richard

Alimenti, “We will change the way lollipops are sold forever!”

For more

information, visit www.ogfc.net