The Bottom Line:

- A wide range of packaging shapes and sizes

- Enhanced safety features

- Configurations for a variety of package formats

Flexible packaging equipment—vertical and horizontal form/fill/seal, flow wrapping, pouches, film, and roll stock—has evolved to the point where it can handle a wide range of packaging shapes and sizes to meet the demands of consumers and retailers.

Consumers are requesting a wide variety of sizes and packaging styles, driven by growth in e-commerce and on-the-go trends in consumption. “In response, bakery and snack producers should seek out equipment with increased tolerance ranges that can be easily adjusted with little to no changeover and develop close relationships with OEMs and material suppliers to quickly adapt to the use of new materials,” says Jorge Izquierdo, vice president of market development for PMMI, Reston, VA.

When it comes to packaging equipment, flexibility is increasingly important, as producers are looking for machinery that can do more. The pressures is on for OEMs to develop more sophisticated systems that can, for example, accurately count and place pieces into a package, and have the ability to produce multiple formats such as stand-up bags and pillow bags.

Beyond traditional flexibility demands, factors such as supply chain volatility and sustainability are putting pressure on suppliers to produce machinery that can adapt to new materials and determine the parameters (temperature, time, pressure) that maintain productivity. “So the issue now is not just the technology itself, but the ability to work with material suppliers and CPGs, test new materials, and have the technical capability to run the material,” Izquierdo adds.

The latest flexible packaging equipment has enhanced safety features. Equipment design and electronics have improved wash-down capabilities and digital technologies help to document and store this information. “These technologies, used in conjunction with labeling and coding equipment, make it easier for products to be traced through the entire supply chain.”

Company

ALLIEDFLEX Technologies Inc.

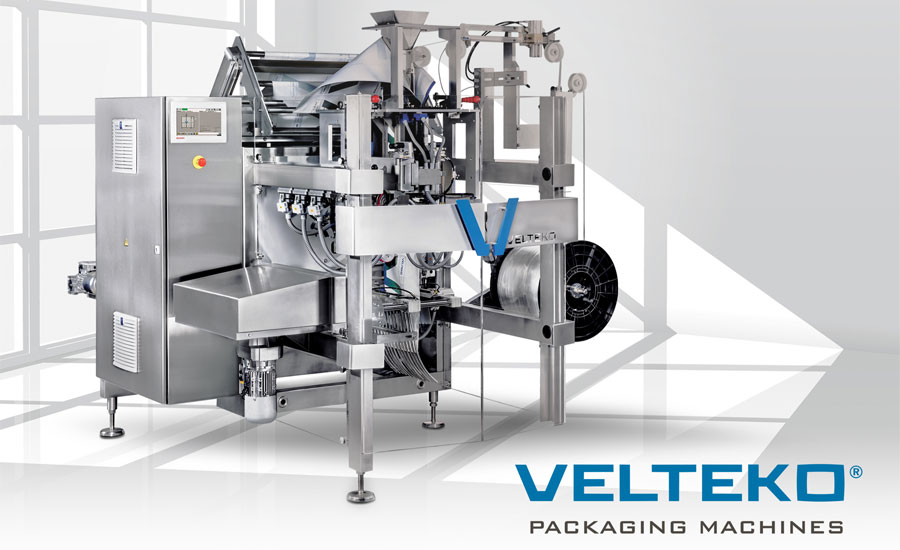

ALLIEDFLEX Technologies Inc., Sarasota, FL, manufactures a variety of flexible packaging machines to suit a host of applications, package formats, and packaging output requirements. “Our VELTEKO VFFS machines can accommodate a single-serve size through the largest club store size,” says Dennis Calamusa, president and CEO. “Our VELTEKO Versatile 360 can accommodate pillow, quad seal, and standup/zipper all on the same machine platform with a five- to 45-minute changeover between package formats.” The equipment can package a variety of snack and bakery items including salty snacks, nuts, trail mixes, extruded snacks, dried fruits, pretzels, confectionaries, biscuits, cookies, and crackers.

Company

Effytec USA

Effytec USA, De Pere, WI, has introduced the HB 20 Horizontal Pouch Machine, an intermittent machine designed to meet the challenges of the horizontal form/fill/seal pouch market. The HB 20 can be configured for a variety of package formats including flat sachets, stand-up pouches, and pouches with spouts, zippers, and straws. Speeds range from 65 to 90 cycles per minute. Features include compact machine design with a sanitary stainless steel construction, motorized vertical seal bars, a low-maintenance cutting device, machine setup recipe storage, and remote tele-modem assistance. Also, the HB 20 offers automatic film splice and alignment, and servo-driven film pull rolls.

Company

Campbell Wrapper Corp.

Campbell Wrapper Corp., De Pere, WI, has introduced a high-speed automatic feeder and flow wrapper that is capable of flow wrapping granola/energy bars at speeds up to 800 ppm as well as small chocolates at speeds up to 1,200 ppm. It can package granola bars, energy bars, chocolates, snack cakes, hard and soft cookies, and a variety of crackers. Food safety features include an open-frame design, cantilevered conveyors that allow crumbs to fall through, easy-to-remove sealing assemblies for offline cleaning, and spray nozzles integrated into the machine for clean-in-place of product carrier parts.

Company

Viking Masek Packaging Technologies

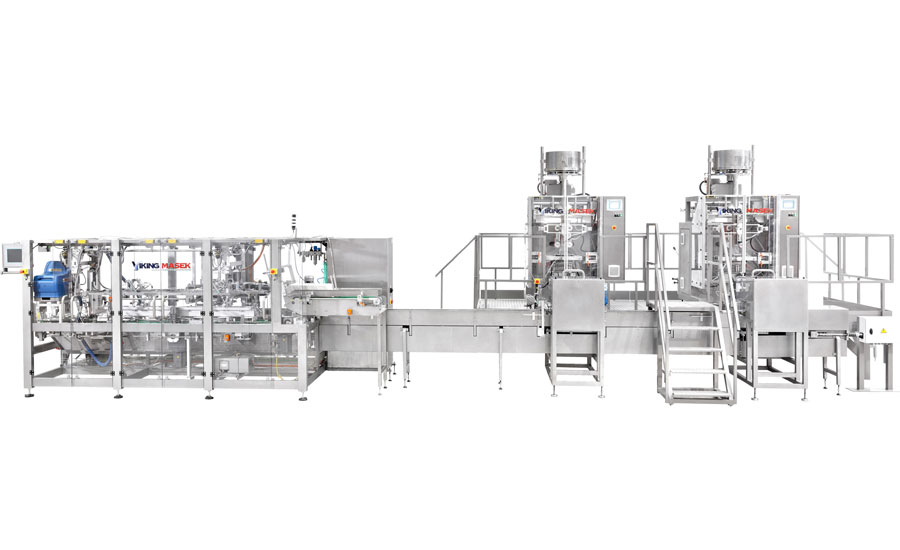

Viking Masek Packaging Technologies, Oostburg, WI, offers the M250 Bag in Bag packaging machine, which combines the bagging capabilities of its M250 with the ability to place small bags inside a larger overwrap bag. Running up to 100 cycles per minute, bags measuring 70 mm by 80 mm are rapidly packed into the main bag in sizes up to 200 mm by 250 mm. The pillow-style vertical form/fill/seal bags can be made with a hole or euro slot for hanging on display racks. The company plans to debut a new machine at PACK EXPO that will set a new benchmark for high-speed pillow bag packaging; details were not available at press time.

Company

Reiser

Reiser, Canton, MA, has made improvements to its horizontal form/fill/seal lines with changeover systems that reduce hand and tool impact, and film protection regarding back-spray or up-spray from wash-downs. “Our Ross tray sealing machines have undergone upgrades in design, access and sanitary features,” says Mike McCann, packaging specialist. “Our Fabbri overwrap machines recently went through a series of changes to improve ease of access and sanitation in their new designs as well.”

Company

Rovema North America

Rovema North America, Norcross, GA, offers the BVI 260 Intermittent Motion vertical form/fill/seal machine, which ensures economical packaging and safe handling of coarse, granulated or powdery products, the company reports. The wide size range and “suit-to-application” add-on modules enable the machine to pack and produce a variety of products and bag styles. For increased efficiency and reduced maintenance, a Sense & Seal function avoids product inclusion in the cross seal and protects jaws. Also, vacuum draw-down belts promote safe handling of materials.

Company

Triangle Package Machinery Co.

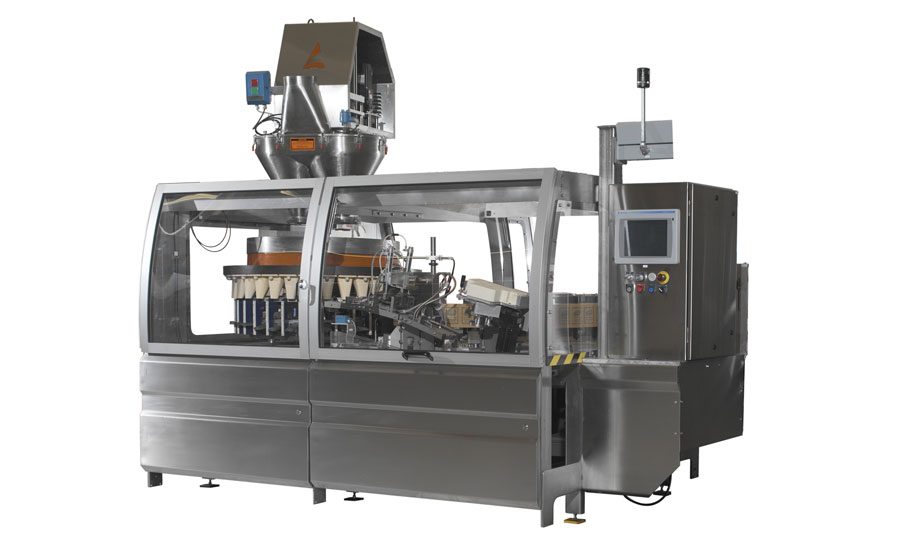

Triangle Package Machinery Co., Chicago, offers the X-Series vertical form/fill/seal baggers in intermittent and continuous motion versions. Features include quick, tool-less changeover; accessible, easy to clean designs; ultrasonic sealing; and integrated zipper applicators. The Model XYRJ—the latest addition to the X-Series line—features an easily rotatable sealing jaw that allows users to run a wide variety of bag styles, including pillow, gusseted, three-sided seal bags and stand-up pouches. The machine is suitable for packaging snacks, nuts and grains, among other applications.

Company

Paxiom Group

Paxiom Group, Las Vegas, offers the VerTek series of vertical form/fill/seal machines, which can package stick pack, pillow and gusseted pouches in a variety of film structures including laminate, metalized and polyethylene. Its family of vertical bagging machines includes the Vertek 800/1200 for pouch widths up to 12 inches and the Vertek 2400 for big bags up to 24 inches wide.

The company’s R2B series of horizontal form/fill/seal machines can run three-sided and four-sided seal pouches with zipper closures as well as shaped pouches requiring die cuts. The machines can be customized to accommodate gas flush, hole punching, middle capping devices, shaped bag molding devices, stand-up pouch formers, vacuum stations, zipper applicators, and rigid spout inserters.

Company

Volpak, a Coesia company

Volpak, a Coesia company, Covington, KY, manufactures horizontal form/fill/seal machines. The company has introduced a continuous motion SC+ poucher for snacks and bakery products, which offers a large production capacity for medium- and large-sized pouches. “The technology is available for companies interested in operating from reels, forming the pouches, filling and sealing them online, and for companies looking for pre-made pouch filling machines,” says Francese Busquets Bueren, head of sales and marketing.

Company

R.A Jones Group

R.A Jones Group, Covington, KY, offers two machines for pouch creation to meet bakery and snack producer needs. The Pouch King PCU-2000 forms and fills a variety of pouch styles from roll web materials at 4,000 linear inches per minute in the standard high-speed size or 7,000 linear inches per minute in the high-speed format. The PCU-2000 features high throughput and reliability for 24/7 operation, patented sealing technology, multiple component filling approaches, and complete cutting, collating, and integrated cartoning systems.

The Pouch King PCA-500 is an adjustable pouch machine that can benefit bakery and snack production operations by acting as either a pouch maker or a pouch maker and filler. The machine can output up to 500 pouches per minute for three-sided, four-sided, and gusseted pouches. Its adjustable design allows users to handle a wide range of pouch widths and heights without the need for change parts.